This weekend I booked progress on the preparation work.

-I made the body mold square and smooth on the inside

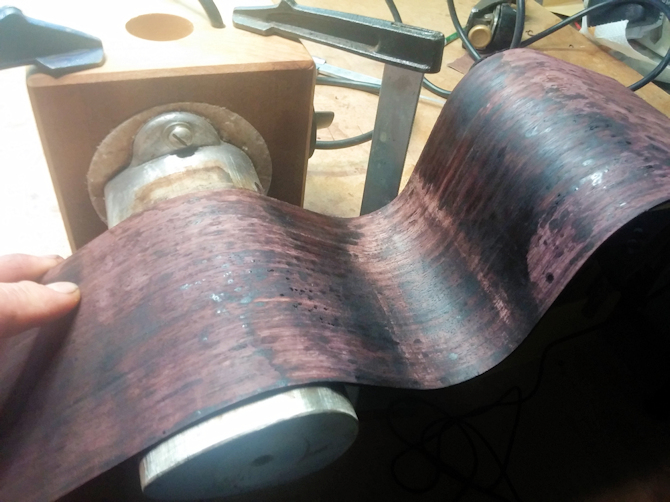

-I thinned the sides to 0.08" and the top to 0.09"

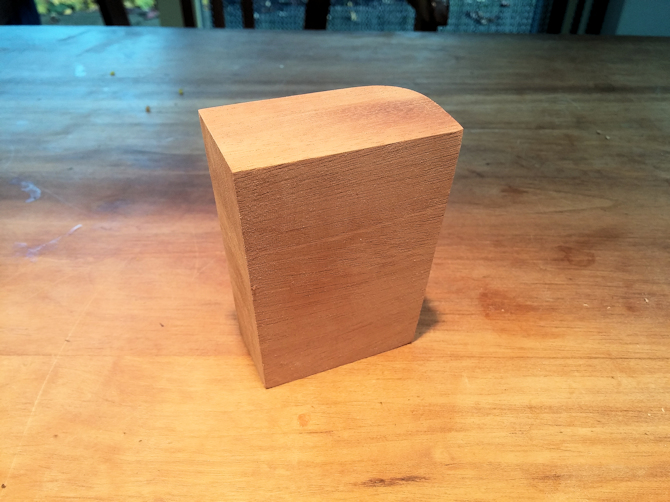

The hemlock tailblock is 0.55" and rounded to accept the sides according to the mold's profile

The headplate is made of a triple veneer with ebony on top

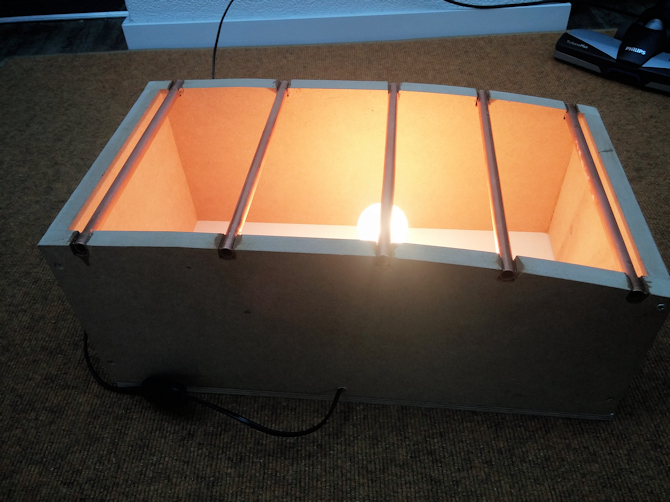

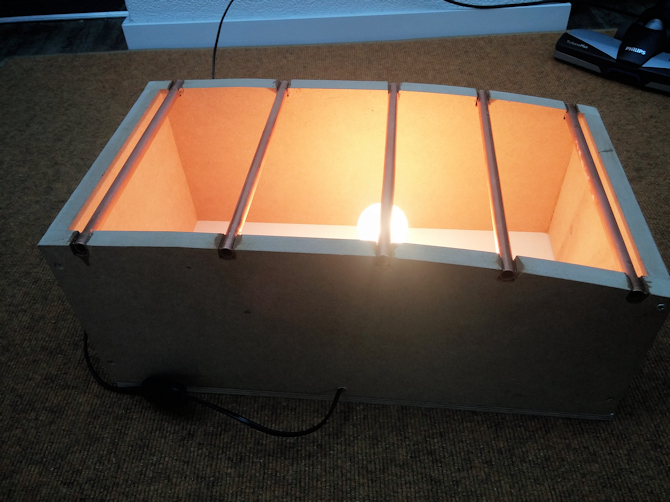

The forming box for bending the top has its warming light attached

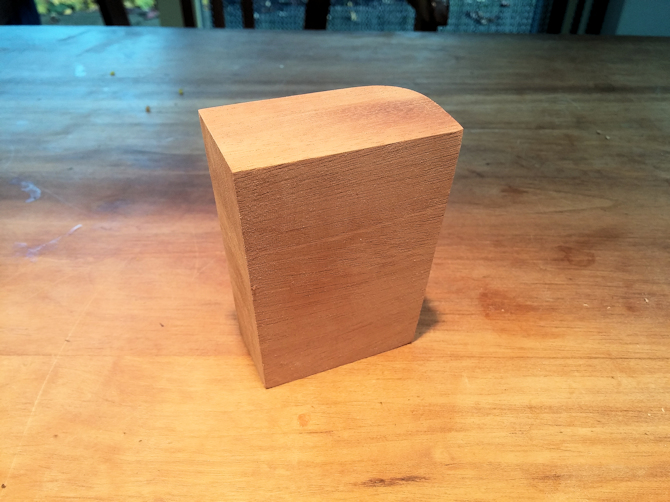

The mahogany neck block is little complicated one. The side of it that has to match the cutaway side. And that has a compound angle.

Looking from its top it has a 1.3 degree angle to match the taper of the fingerboard.

Looking from the front side it has a 5 degree angle to meet the heel, which has that taper too.

My band saw has the adjustment options to make that cut in one pass. But think twice and cut only one time. Ha!