Second Falcate Classical with strings!

Posted: Mon May 04, 2015 11:03 pm

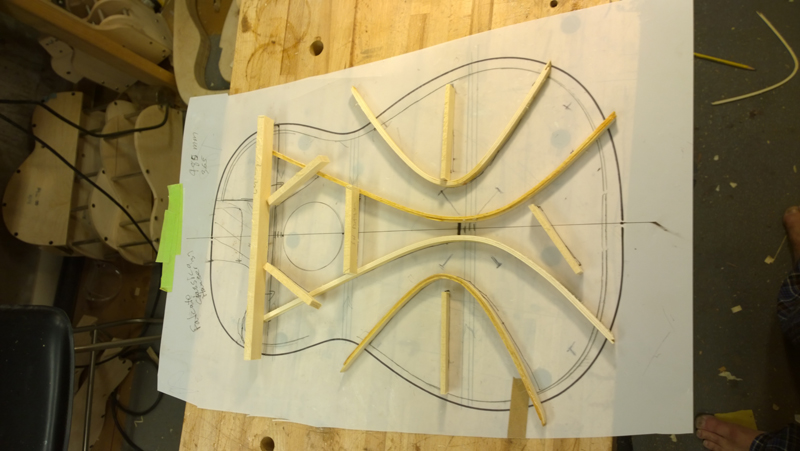

As I am building the same guitar as my last. I decided not to blog this build, I will highlight any new procedures that differ from last project. This guitar is a commission from my classical guitar instructor. He loved the sound of the last more importantly though is he really like the ergonomic features I added. Slightly narrower nut and the 20" radius on the fret board. He also like the cutaway. For this guitar I selected a nice engelmann spruce top and panama rosewood back and sides. The tap quality and the stiffness of the rosewood was outstanding. I picked up the rosewood set a couple of years ago from LMI. I went totally classical and chose spanish cedar for the neck. Other than the wood the only design difference is that I will make the braces a mm taller based on the results of my last guitar. Also I am trying to avoid all of the hidden mistakes I had in the last one. So far that is going well.

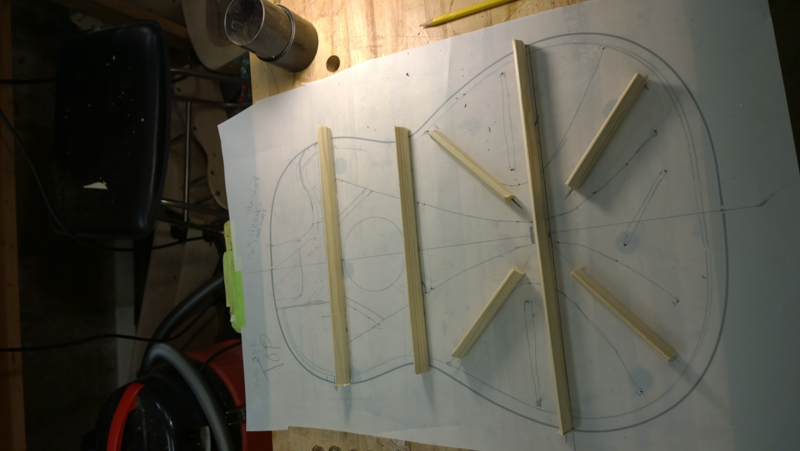

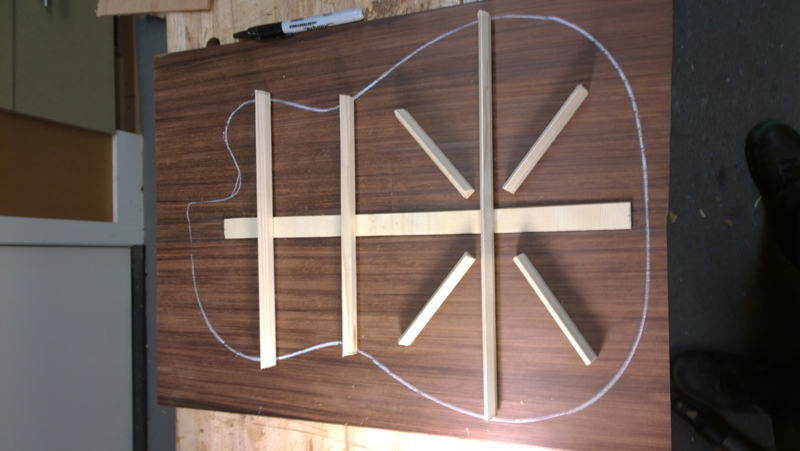

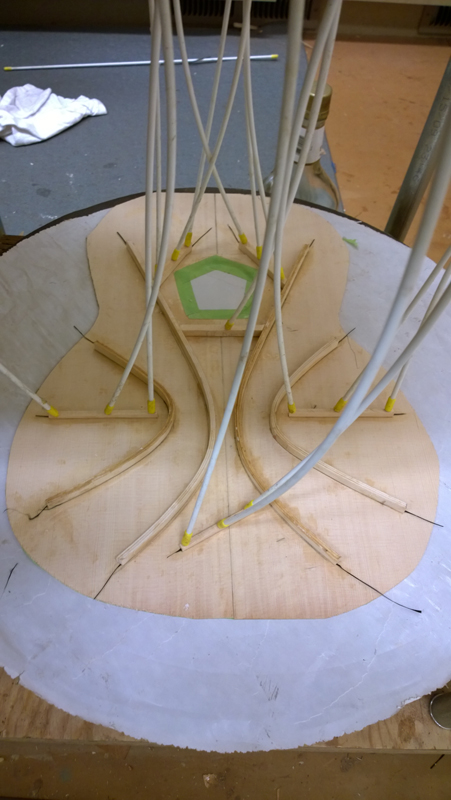

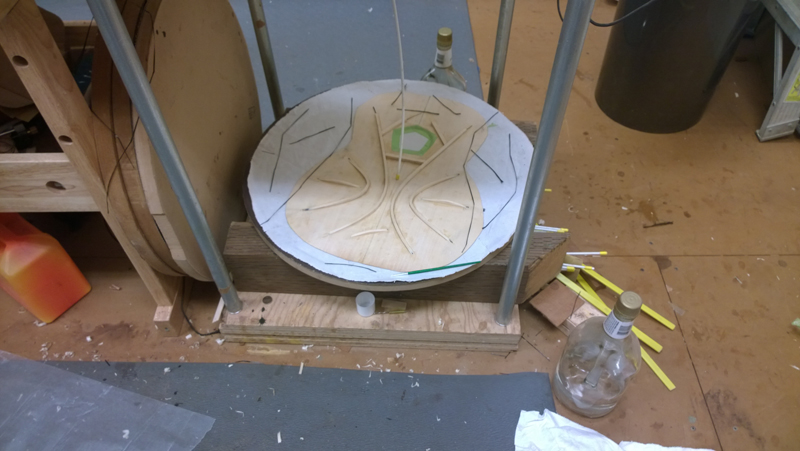

So far I have the rims built and profiled, the neck has been prepared and I am starting on bracing the top and the back.

I went away from my neck jig and just used a table saw for the tenon. The advantages of the table saw is I can still set the neck angle, but I van also angle the cheeks making it easier to fit the neck on the body. Also the procedure was so clean compared to mucking with the 1/2 inch router bit. I have a sawstop saw, so I am less nervous about cutting my fingers off. Ultimately I will build a sled to make this an easier process. The neck will be a bolt on bolt off neck. The Spanish cedar glued to the fret board will be planed to a wedge to create the negative angle required for a classical.

I posted my rosette build viewtopic.php?f=9&t=2291

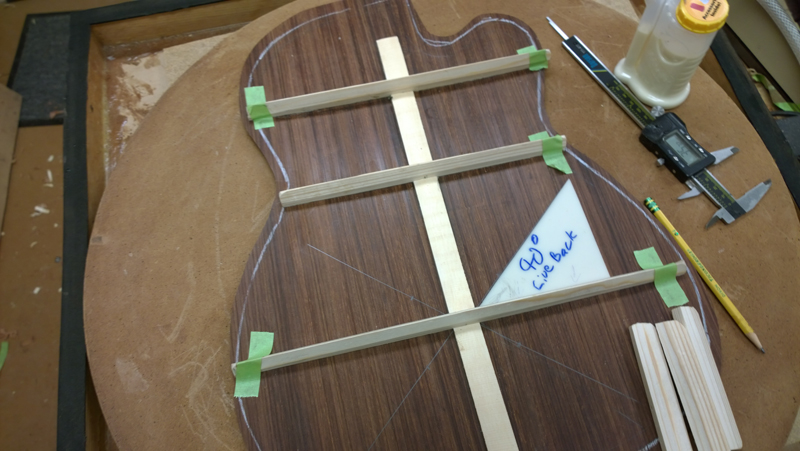

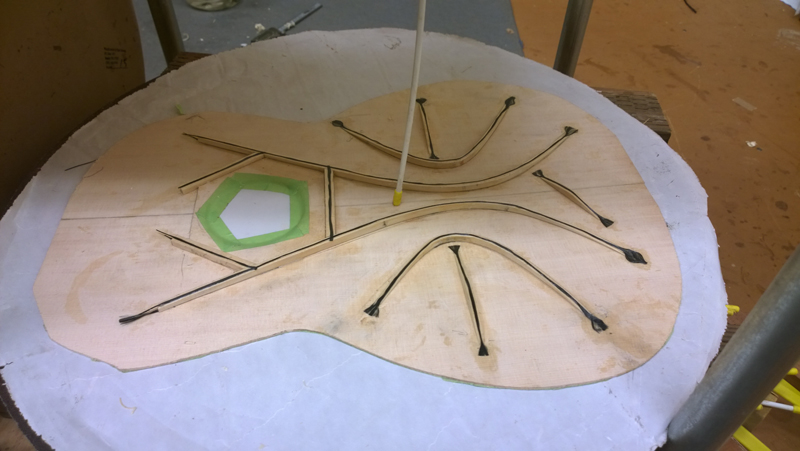

Today I installed the sound hole patch and am starting the back

So far I have the rims built and profiled, the neck has been prepared and I am starting on bracing the top and the back.

I went away from my neck jig and just used a table saw for the tenon. The advantages of the table saw is I can still set the neck angle, but I van also angle the cheeks making it easier to fit the neck on the body. Also the procedure was so clean compared to mucking with the 1/2 inch router bit. I have a sawstop saw, so I am less nervous about cutting my fingers off. Ultimately I will build a sled to make this an easier process. The neck will be a bolt on bolt off neck. The Spanish cedar glued to the fret board will be planed to a wedge to create the negative angle required for a classical.

I posted my rosette build viewtopic.php?f=9&t=2291

Today I installed the sound hole patch and am starting the back