Page 1 of 5

Installing tenon brass inserts

Posted: Fri Jan 20, 2012 12:11 pm

by ken cierp

The most important aspect of this operation is to have the correct insert -- which is the

course outer thread 1/4-20 style. The fine threaded inserts sold at most wood worker supply center are way too large on the outside diameter.

Our fixture serves several purposes -- the tenon is gauged for size, it is securely captured to prevent split out, and the table keeps the installation tool perpendicular -- this is important, an insert that is out of alignment can cause problems down the road.

Re: Installing tenon brass inserts

Posted: Wed May 09, 2012 9:24 pm

by Tj Turner

Ken...

Do you have a suggested place to find the inserts?

Thanks!

Tj

Re: Installing tenon brass inserts

Posted: Wed May 09, 2012 10:07 pm

by ken cierp

LMII has them for a zillion dollars a piece or you can get them here

http://www.microfasteners.com/

Re: Installing tenon brass inserts

Posted: Thu May 10, 2012 9:40 am

by Dan Pennington

I use this driver from Rockler in my drill press. Helps me keep them going in straight.

Then I squirt some thin CA glue around the threads to toughen up the end grain. This is a cedar neck from an all cedar guitar. The cedar needs some toughening up to keep the inserts from pulling out under pressure.

Re: Installing tenon brass inserts

Posted: Thu May 10, 2012 10:01 am

by ken cierp

The CA is a good practice we do that as well.

Again I do not recommend the use of that fine thread insert -- the OD is too large for a thin wall application and once the tenon is cut the wood left is marginal. Dan I know you have had success but I'd suggest the course thread insert as an improvement. The course thread insert I pictured is the same one used by Martin as well as other manufacturers. If one tries to insert the fine thread insert after the tenon is formed splits are very likely.

Re: Installing tenon brass inserts

Posted: Thu May 10, 2012 10:22 am

by ken cierp

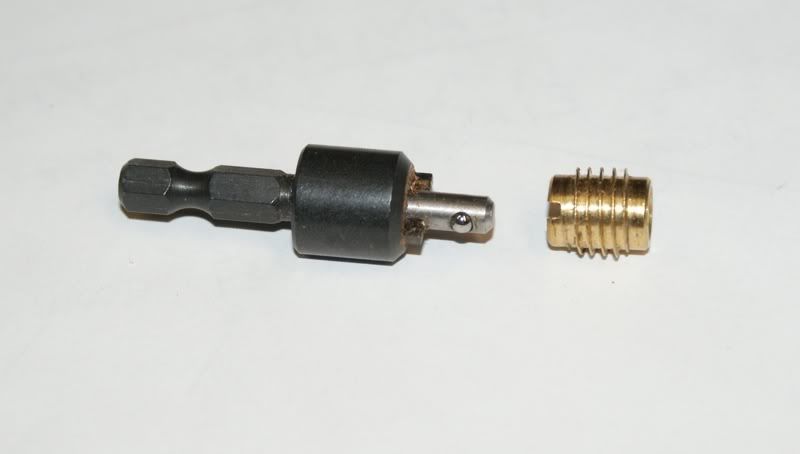

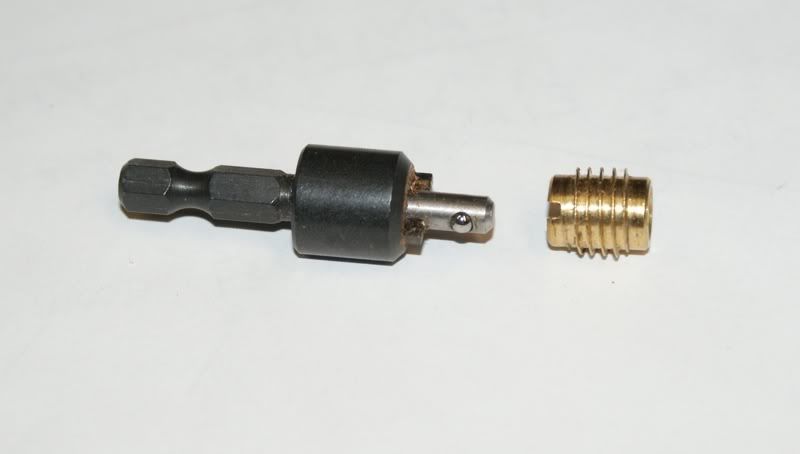

Here's the gadget we use to install the inserts -- purchased from Harbor Freight

The "insertion tool" is simply a cut-off bolt and two nuts, catch the insert on a few threads run down snug, hold the nuts with an open end wrench and reverse the drill motor. Oh -- the end that looks like a screw driver slot is really part of the tread cutting process and

it goes into the pilot hole.

Re: Installing tenon brass inserts

Posted: Thu May 10, 2012 11:43 am

by Dan Pennington

I agree with you completely about using the coarse thread inserts. The insert in my photo above was just the one I grabbed to make the picture with the insert tool.

I use a butt joint with a fairly wide heel, so I don't worry about the tenon splitting.