Thanks Tony,

Kevin pushed me to start this thread, and now he wants me to show how I make the neck. Well fine, here's the followup:

The fingerboard and headstock get a lot of inlay. It would be a shame to do all that work and screw it up with the dovetail. That is why here the joint comes first.

The routing you saw above is a precise, but not a very interesting subject. So when that is done I start two things first. The angle toward the bridge. I aim, when the neck is flush with the body, for a little gap between the top and the straightedge (on top of the neck). About 1,5 mm.

so when that is too small, like on the picture, I take off some wood of the bottom end of the neckside.

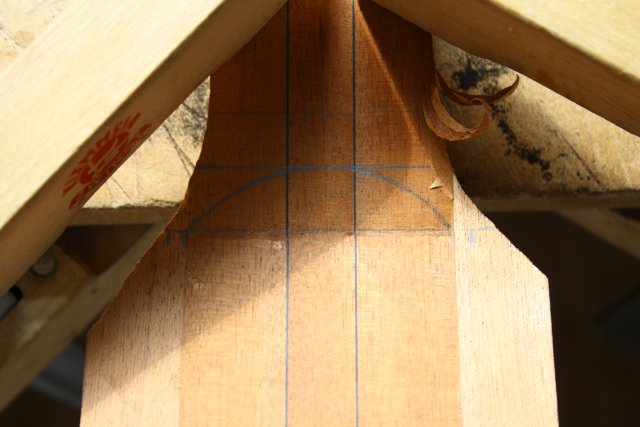

Along with this procedure I want to have the neck be pointed at the middle of the top. if that is out of direction, I take a little wood of the side of the neck. At this point the sides of the neck are straight and parallel. So I can easily, with the straightedge on both sides of the neck, if all is centered.

So when the neck is alligned to the center and with the right angle it just sits a little too high in the joint. Now there is time to make the neck sitting on the sides as flush as possible. therefor I ´sandscribe` the neck, sitting on the side. Sandpaper between the two and gently pull it out toward the heelend. This was the neck sands to the profile of the sides.

Go slow and use your eyes and you can make it almost immaculate.

When the angel, the centering and the side of the joint are right, the neck needs to be lowered into the body.

I use some chalk for this purpose. Put it on the dovetailside of the neck.

Push the neck firmly into the body and you can see where the high spots are. If you do this over and over, you will see that the joint get tighter and tighter.

Again take your time and take off some wood of the neckside until the neck is flat with the body. You do not want to go too far, ´cause then you need to glue on a veneer and start over. Not a big deal, but annoying.

And when all works out, there will be a dovetailjoint that is flush, tight, and right angled. Here the straightedge sits the aimed 1,5 mm above the top. Don´t be frightened, If I can,you can do it! I had some flaws before too you know, but here I am very happy.