The body:

The top is .100; the sides are .075; and the back is .090. The length is 17 15/16";

The lower bout is 11 1/2" W; the waist is 7 5/16"W; and the upper bout is 8 5/8"W The depth or height at the rear tail block is 3 3/4"D; the waist is 3 7/16"D and the upper bout is 3 5/16"D and the heel is 3 1/8"D.

The lower bout back appears to be 25' radius that flattens out at the waist forward; The length very close to the same. The top is 1/16" low from the bridge location to the sound-hole but otherwise is flat.

Again, the sides and back are Brazilian and the top really appears to be Sitka or German Spruce, it's hard to tell...for me anyway...

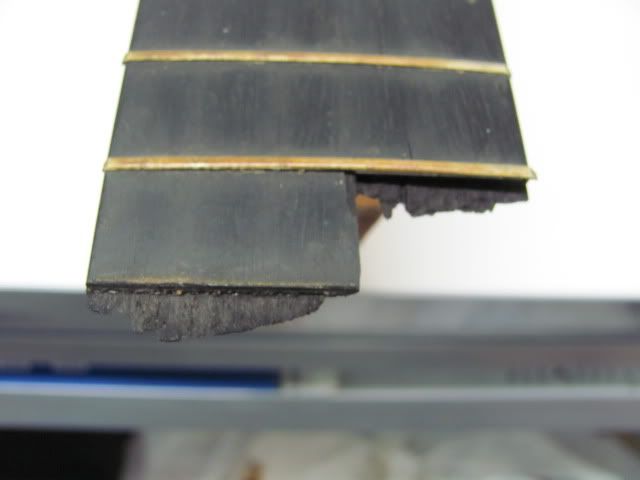

IT would appear from the string pieces that I removed from the tuners that it was strung with 13's thru 52's and the tension simply pulled the neck off the guitar. As you will see in the pics....there isn't much in the way of glue failure...it simply pulled the wood apart...the neck attachment is interesting, it's a curved teardrop shape that is 2" at the top and 5/8" at the bottom. There was a mortise and tenon joint pretty close to the center that was an extension of the brace that ran from the tail block through the neck block and into the neck. I have no idea how deep. it measures 15/16" high and 1/4" wide and apparently was meant to be a method of stabilizing the neck. The neck sits 3/16" deep into the neck block and is otherwise a "Butt joint" all glued with hot hide glue.

Here are some Pics...notice the M&T at the center of neck joint that I have colored a bit with a pencil so it can be seen...it appears that the neck block is spruce and the tail block is Brazilian RW.

I'm not a very good photog, and I don't want to be too pic heavy so I've tried to pic out those of the most interest...

I have ALL the pieces...right down to the smallest....it all fits together like a jigsaw puzzle. The frets are not "T" shaped, they are BAR frets. They are somewhat worn...then neck shows that it was really played at EVERY position all the way up the neck. Not sure I want to mess with the neck..the only parts broken are on the extension.

concerned about attaching the neck....make another mortise an tenon...use a bolt with an inset...screws? There is VERY little room inside with that center bar to get at the heel block...only a child could get there hand inside to repair the cracks on the top like you see the other guitar was repaired unless one removes the back...the maple binding is very fragile....not sure one COULD remove the back w/o destroying the binding...but I don't know...not REALLY sure how to do the neck set...the neck is as straight as it can be...no twists or curves...a tiny bit of back-bend and I think that's "Built-in" for string tension...but again...I'm a new-be. All the help an suggestions will be greatly appreciated...if I've Miss-spoken..say so...not thin-skinned! Unless my cat gets PO'ed at me and bites me anyway! Thanks for looking...

Oh...the neck is 12 frets to the body...the nut width is 1.78 and 2.155 at the12Th fret...it is also .07715 thick at the nut and 1.015 at the 9Th fret just prior to the curve up the heel. it has a very deep "V" shape that's very comfortable. it's also a 24.5" scale.

Ray