Sorry to have confused the build by changing the internal structure of the the kit. But I thought it would make a better guitar. Beard might disagree, but he' not in my basement.

The walnut ring, the sound posts, and the back braces replace the basket. The ring and the basket do the same thing - each acts as a shelf for the spun cone to sit on.

Yes, the walnut ring is not supplied with the kit.

I'm using a McDonalds wifi to post this but after I get home in a couple of days, I will try to find some photos oh how the basket fits into the guitar. Unless someone beats me to it.

And, this will be a round neck for fingerpicking.

Beard Reso Guitar Kit

Re: Beard Reso Guitar Kit

OK got it -- makes sense to me. Seems it may reduce the overall weight too.

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

-

Dan Pennington

- Posts: 76

- Joined: Mon Dec 19, 2011 1:52 pm

Re: Beard Reso Guitar Kit

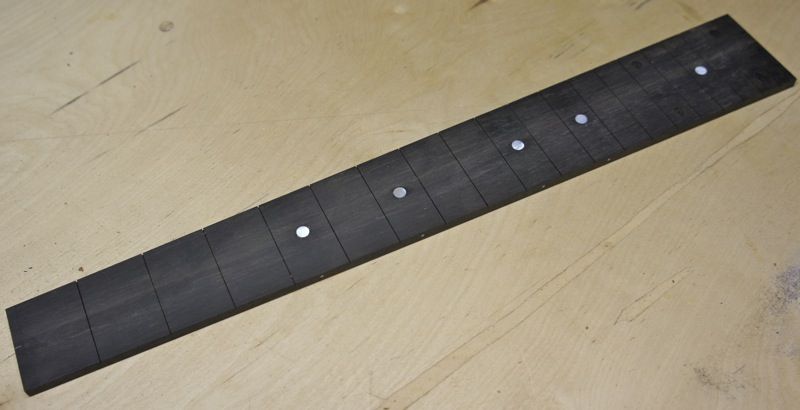

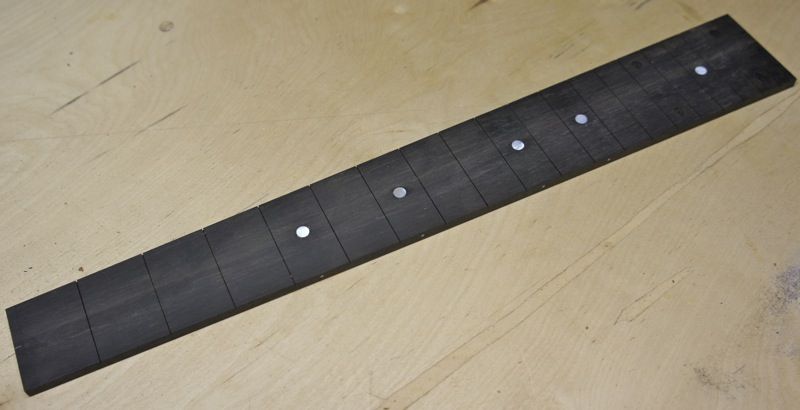

I got back to work on this kit today. Did some dot inlays on the finger board and some side markers.

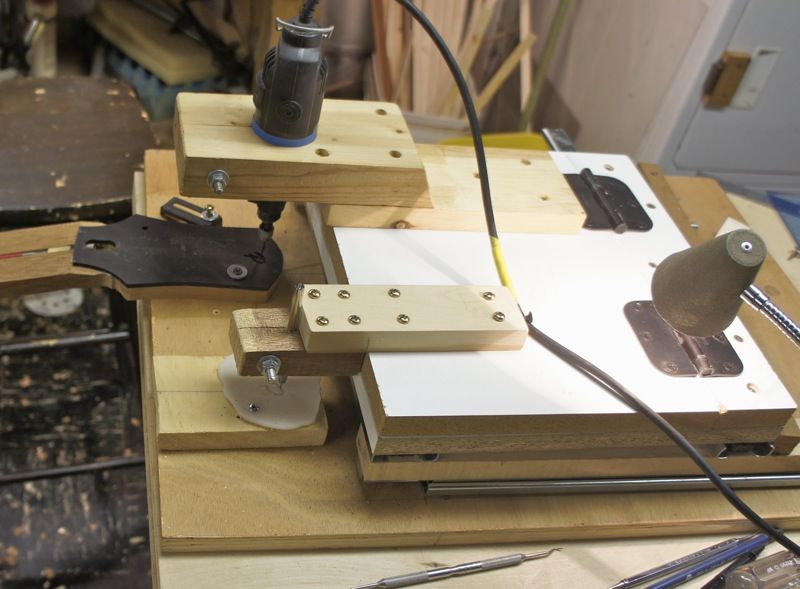

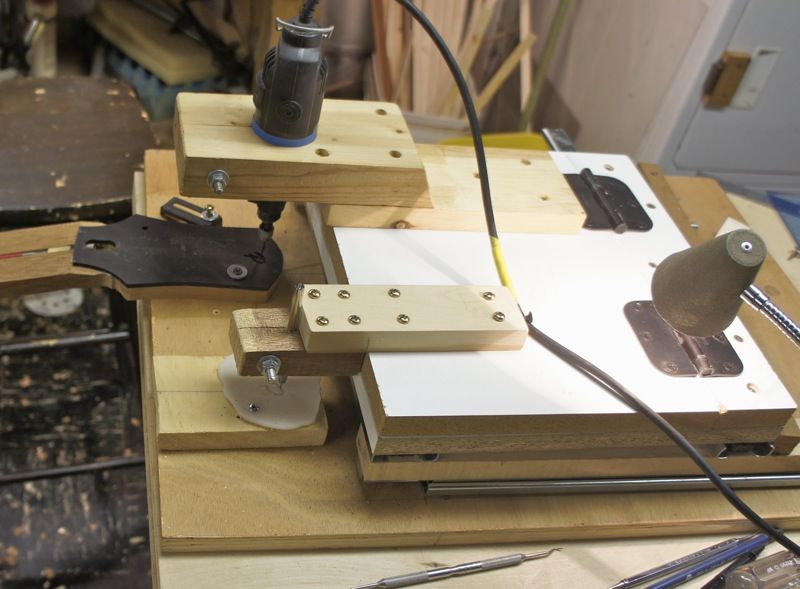

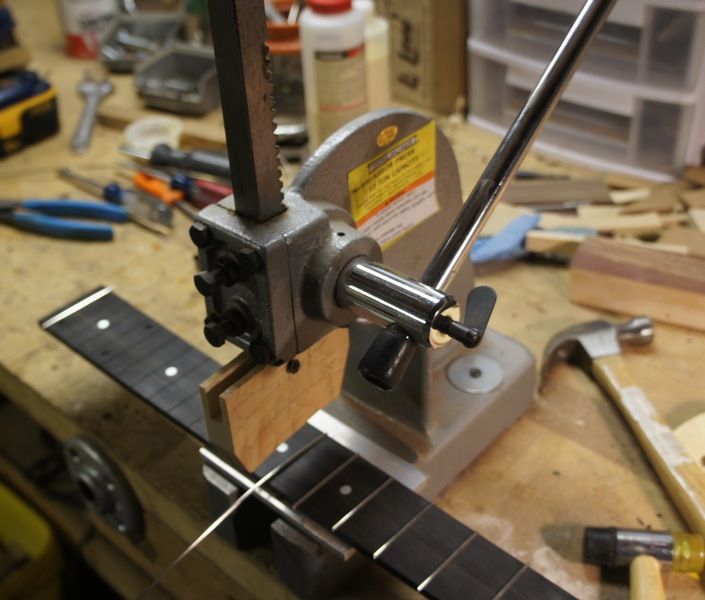

And used my inlay router pantagraph machine thingee to inlay a P in the head stock. Based on one made by Keith MacKenzie and demoed on youtube by guitar gadgeteer Chris Paulick. It uses two sets of drawer slides to give two dimensional movement and the hinges on top allow vertical movement.

A mold of the inlay piece is made of Friendly Plastic. The plastic gets soft in hot water and solidifies at room temp. The stylus follows the mold and the Dremel cuts the cavity.

And the result.

A little bit of ebony dust and some CA glue and it will be permanent. Tomorrow I'll fret the board and glue it to the neck.

And used my inlay router pantagraph machine thingee to inlay a P in the head stock. Based on one made by Keith MacKenzie and demoed on youtube by guitar gadgeteer Chris Paulick. It uses two sets of drawer slides to give two dimensional movement and the hinges on top allow vertical movement.

A mold of the inlay piece is made of Friendly Plastic. The plastic gets soft in hot water and solidifies at room temp. The stylus follows the mold and the Dremel cuts the cavity.

And the result.

A little bit of ebony dust and some CA glue and it will be permanent. Tomorrow I'll fret the board and glue it to the neck.

Re: Beard Reso Guitar Kit

Hey Dan that copier "thingy" is pretty cool and looks simple enough to construct -- do you have a plan you could share in the "specialized tool section"?

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

-

Dan Pennington

- Posts: 76

- Joined: Mon Dec 19, 2011 1:52 pm

Re: Beard Reso Guitar Kit

No, I don't have any plans for the inlay machine. I used Mackenzie's as a model and just put scrap wood together till it did what I wanted it to. I don't feel right taking any credit for the idea. People should go to youtube and see the original Mackenzie/Paulick version.

http://www.youtube.com/watch?v=8PQlDAg971c

And copies of his machine by two other guys.

http://www.youtube.com/watch?v=TYCubwav ... re=related

http://www.youtube.com/watch?v=0Qad45qX ... re=related

http://www.youtube.com/watch?v=8PQlDAg971c

And copies of his machine by two other guys.

http://www.youtube.com/watch?v=TYCubwav ... re=related

http://www.youtube.com/watch?v=0Qad45qX ... re=related

-

Dan Pennington

- Posts: 76

- Joined: Mon Dec 19, 2011 1:52 pm

Re: Beard Reso Guitar Kit

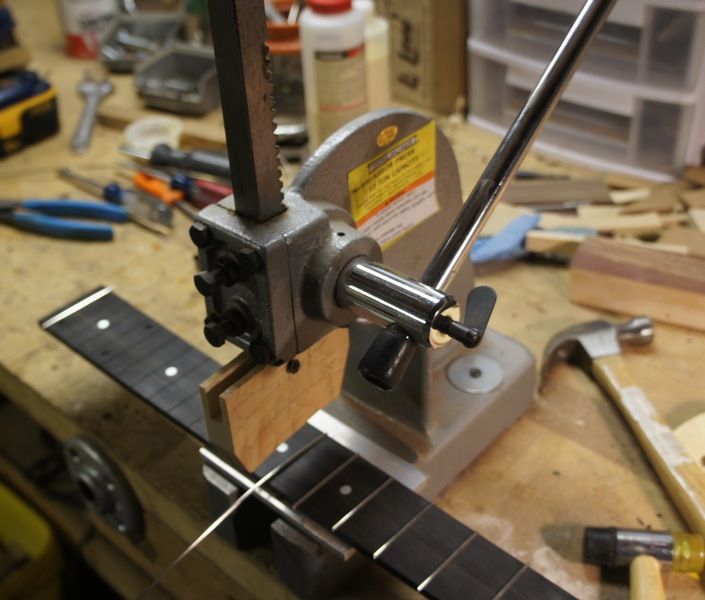

I pressed in the frets with my Harbor Freight arbor press. I adapted it to take the StewMac cawl. I have only one cawl insert that is for Martin finger boards and that's 16 inch radius. The finger board on the Beard is almost flat - probably 20 inch or more. So I made my own curved cawl to fit the board from some hard maple. Worked just fine.

Then I glued it to the neck and did some rough shaping of the neck. Looking like it might grow up to be a guitar.

At this point in the assembly, I think I will do some sanding on the neck to get it feeling good to my hand. Then I'll apply a couple of coats of shellack to just the back of the neck just to keep the raw wood from absorbing crud from my hand while test playing. Then I'll mount all the hardware and string it up to see how it fits and sounds and feels. Just to make sure that I haven't done something dreadfully wrong that can be corrected before I apply a finish.

Then I glued it to the neck and did some rough shaping of the neck. Looking like it might grow up to be a guitar.

At this point in the assembly, I think I will do some sanding on the neck to get it feeling good to my hand. Then I'll apply a couple of coats of shellack to just the back of the neck just to keep the raw wood from absorbing crud from my hand while test playing. Then I'll mount all the hardware and string it up to see how it fits and sounds and feels. Just to make sure that I haven't done something dreadfully wrong that can be corrected before I apply a finish.

-

Dave Bagwill

- Posts: 5951

- Joined: Tue Dec 13, 2011 7:44 pm

Re: Beard Reso Guitar Kit

Looking very good! How wide is that headstock at the widest point? I like that, gives plenty of area for making it distinctive.

-Under permanent construction