Thanks guys, ... These cutaways are a pain. Early on I promised myself that I was not going to make cutaways. Unfortunately I did not keep that promise. It sure adds a lot of time in a lot of the procedural steps. Each time I learn something or try a new idea I seen in other's blogs.

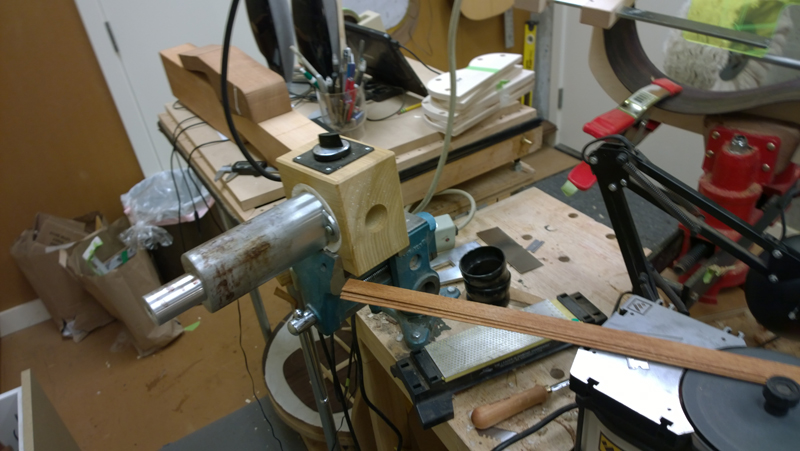

Continuing to build components before starting the assembly of the guitar I have had time to fabricate the end blocks and bend the a bunch of mahogany to make the laminated linings for the top side of the rims.

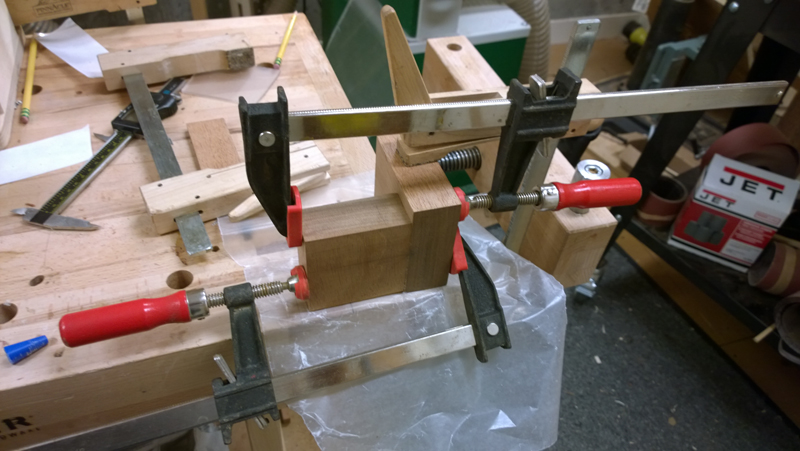

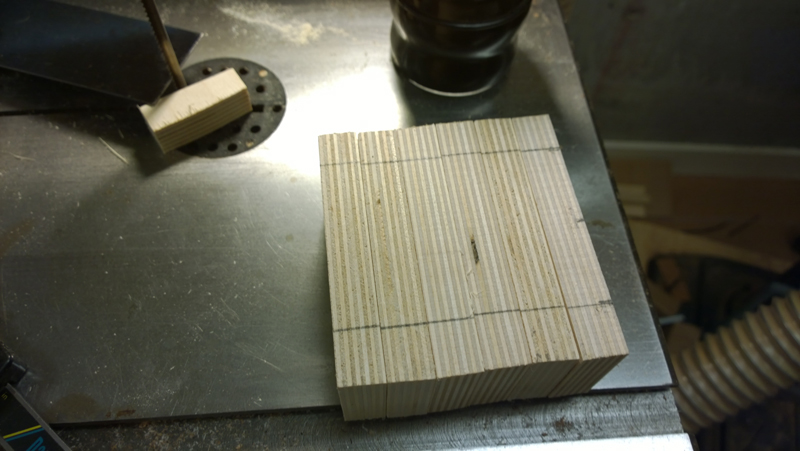

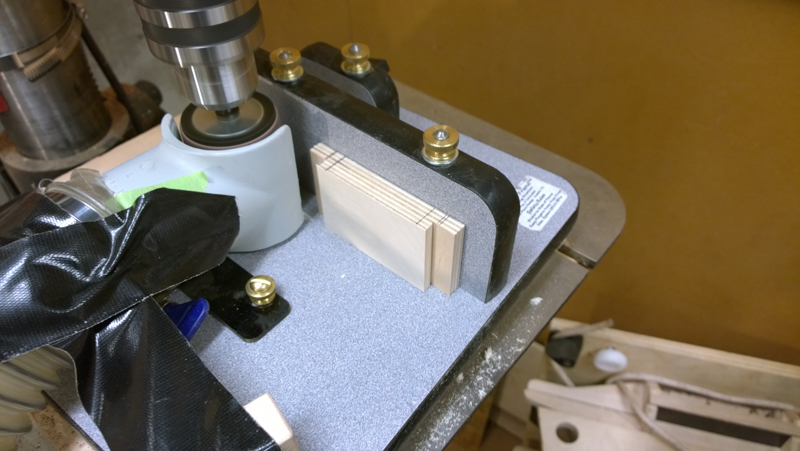

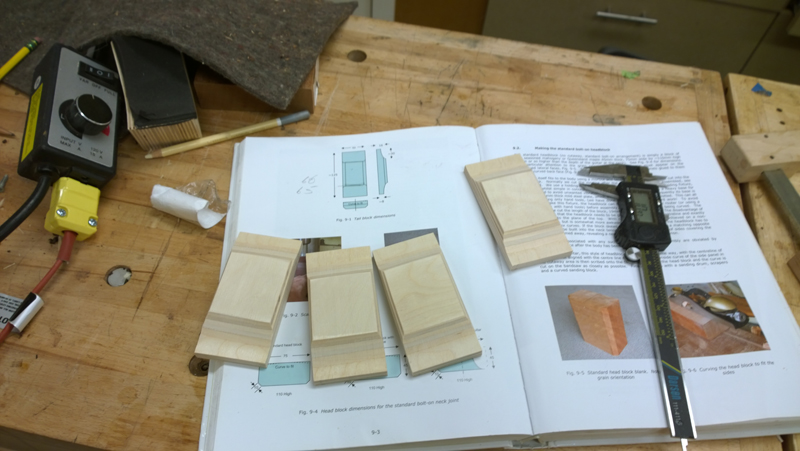

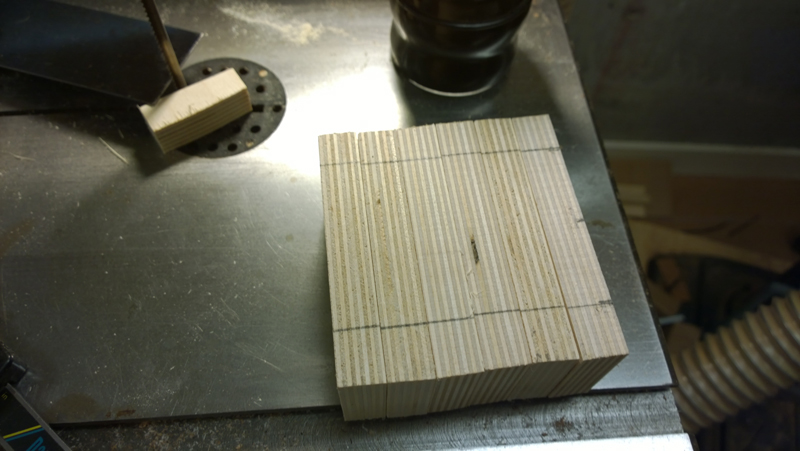

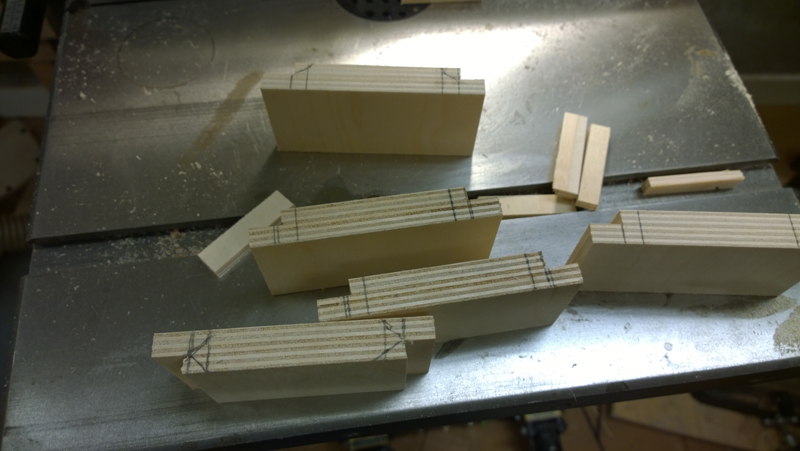

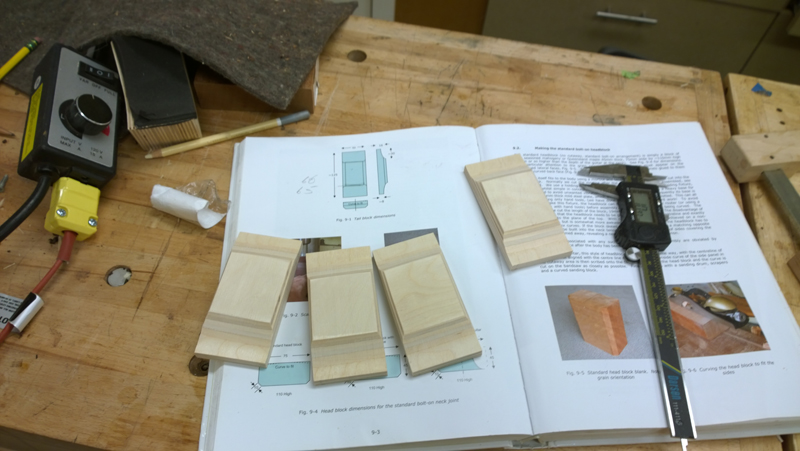

The neck block for a bolt on bolt off neck takes a bit of work to support a mortise for the heel of the neck and a second mortise to support a tenon under the fret board extension. Not a big deal, the main part of the task was to find a large enough block of mahogany that allowed me to make blocks with the grain running the right way. Luckily I had a large bock intended for a classical Spanish heel that I was able to cut to make two fretboard extension support block and still have a large enough block for the heel. Once the heel bock and

fretboard extension block were cut to dimension I glued them together.

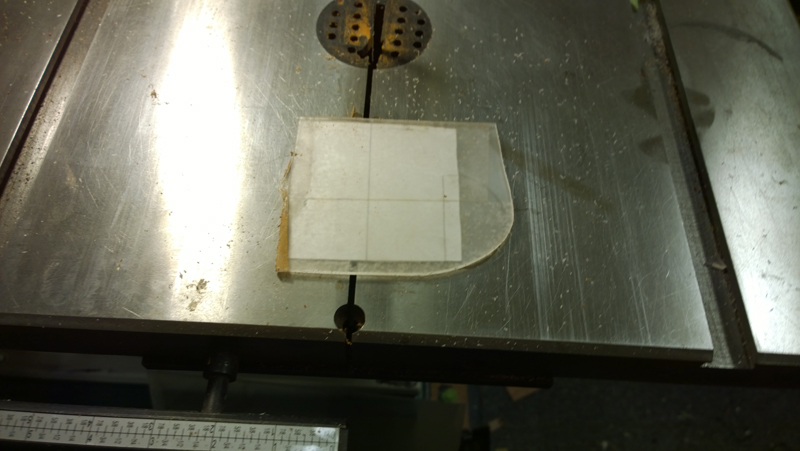

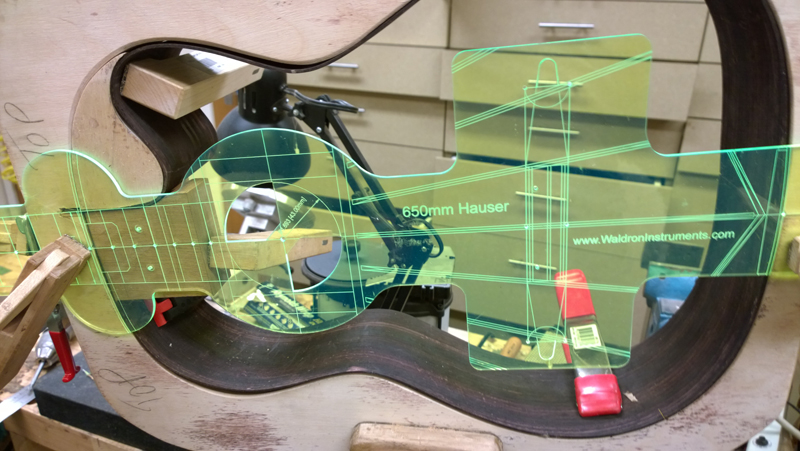

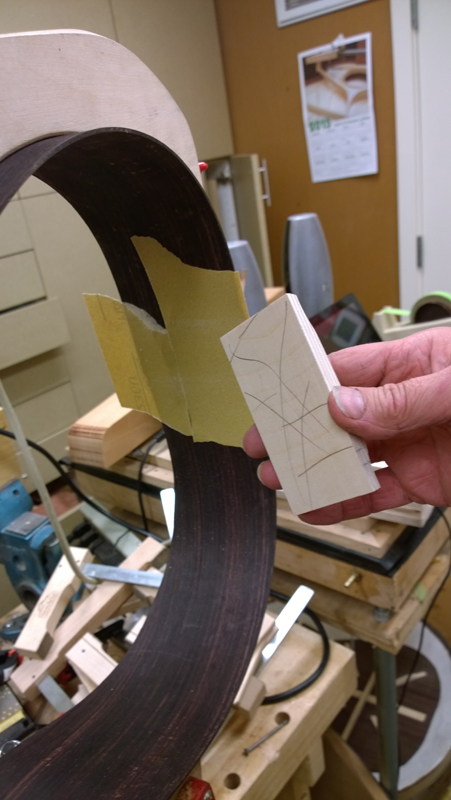

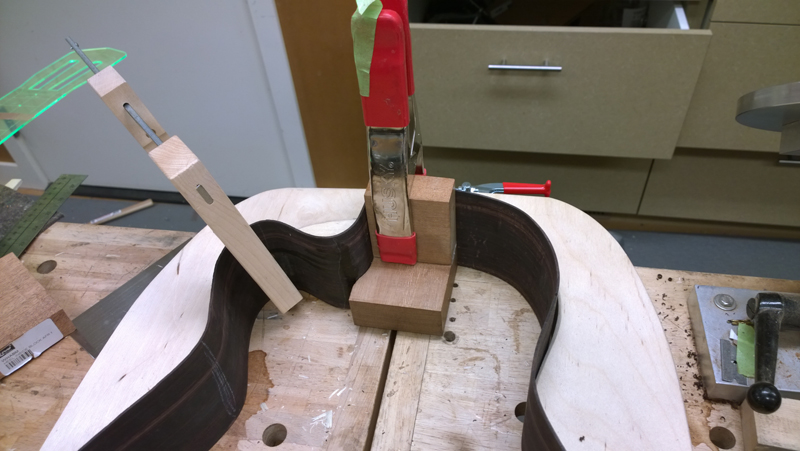

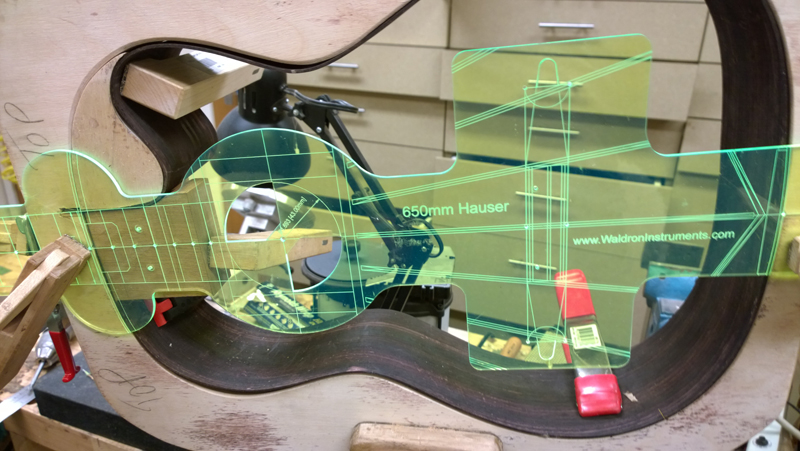

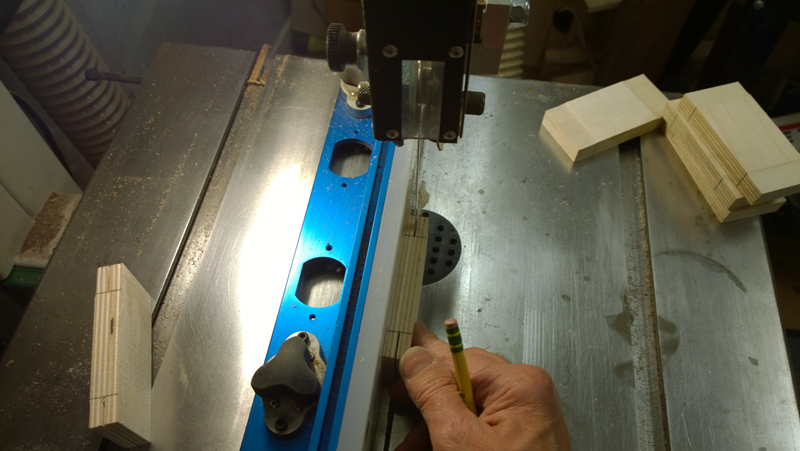

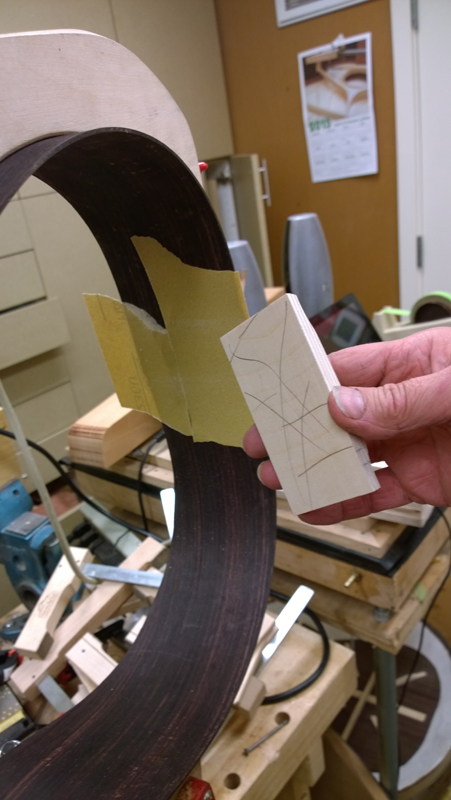

As this is the first time building this style of classical guitar I used the mold to make a template for the fret board extension block profiled for the cutaway. My cutaways have an absolutely flush joint between the cutaway side and the neck, so much care must be taken to assure that the side will be in the correct location relative to the center line. (basically half the width of the fret board at the 12th fret.

But

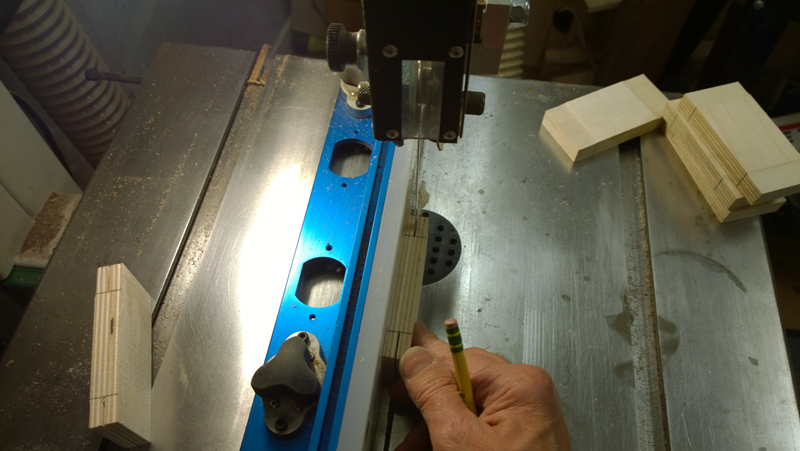

BIG whoops! cut the cutaway profile on the

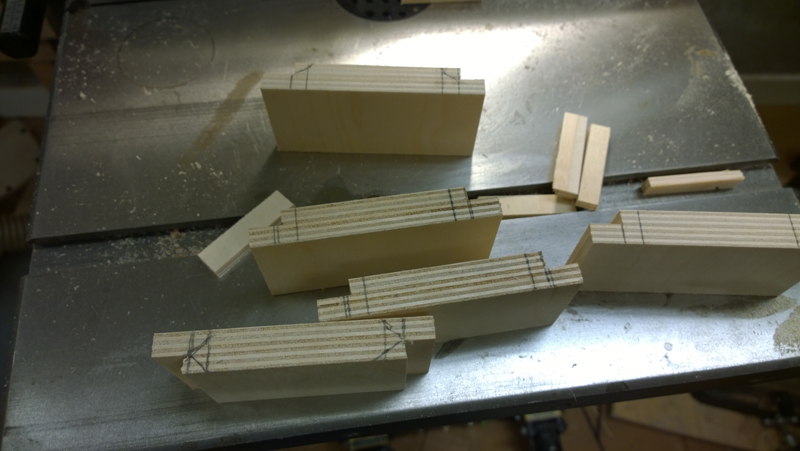

wrong side. Luckily I had enough wood and made two extension blocks

Cut the heel block off and cleaned it for reuse, glued the new block on and finally profiled a cut the correct side

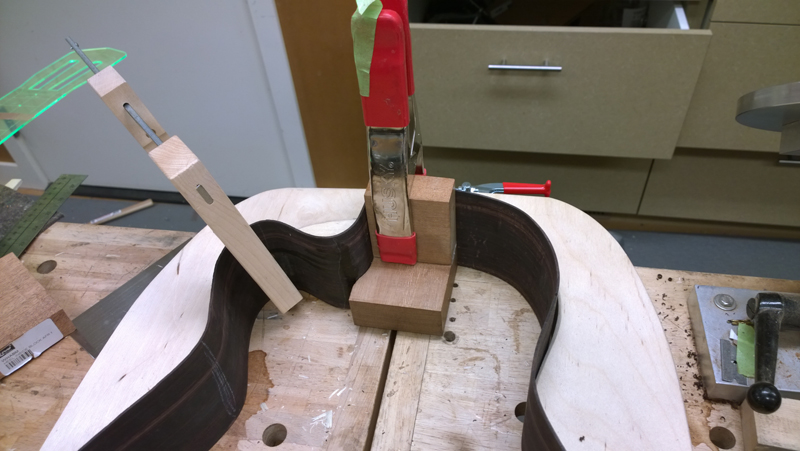

You can sort of see how the extension works and how the side meets the neck in the following photo.

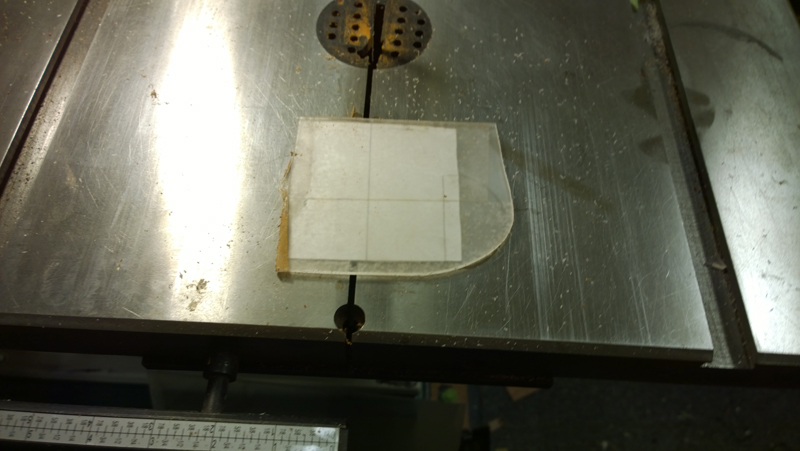

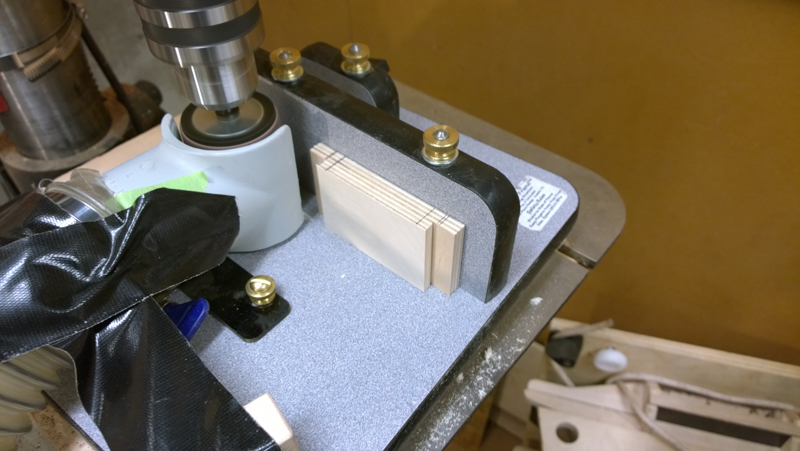

I made a handful of tail blocks to have some on hand. I make the same side for all of my guitars. I used 3/4 birch plywood. To make I cut the wing to dimension on my band saw and used my luthiers friend as a drum sander to cut the curve into the wings. Then just a bit of cleanup on my belt sander.

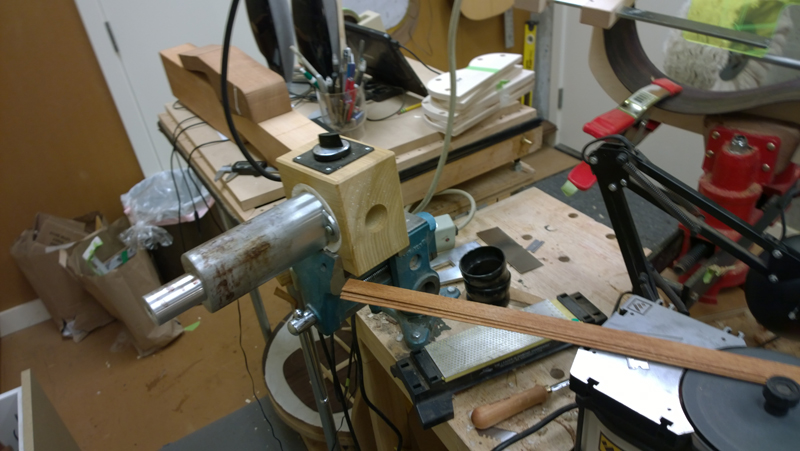

To make the laminated binds I used a couple of orphaned mahogany sides that I had purchased in a deal for bunch of orphaned sides. The Gore\Gilet build book suggested using three ply each ply about 2.2 mm. I decided four 1.8mm plys my make bending the cut away easier. I just used my Blues Creek bender to bend the non cutaway. The curves are gentle enough that I can stack them together. I hand bent each of the cutaway so that they would nest properly. The curves on the outside ply sure get small. In any case it gave me a bit of bending practice.

I just ripped the bend side for the non cutaway into four strips. I stored them on the bending molds that I have used.

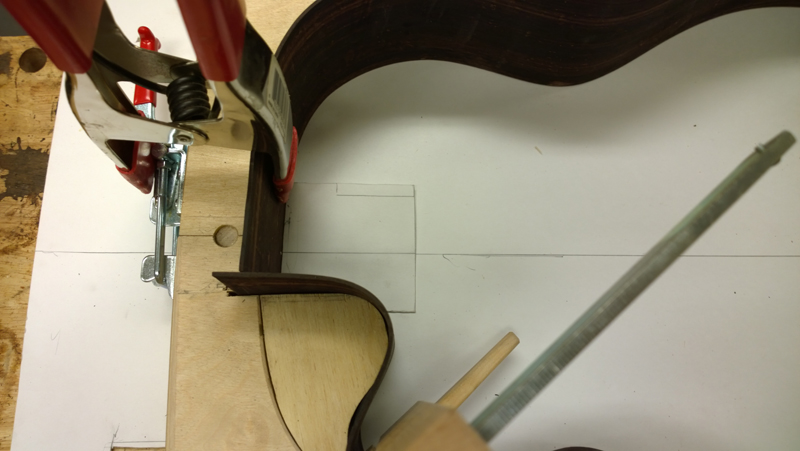

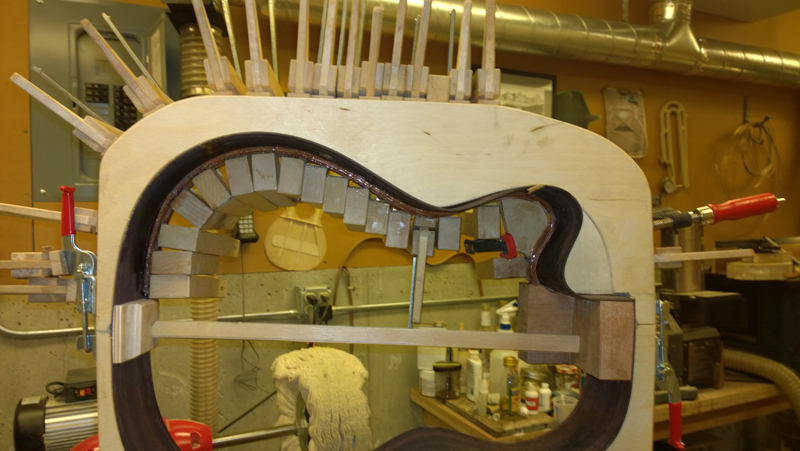

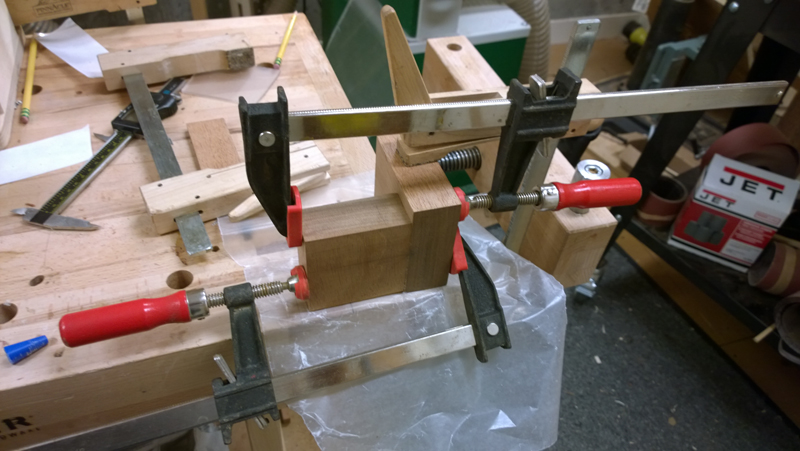

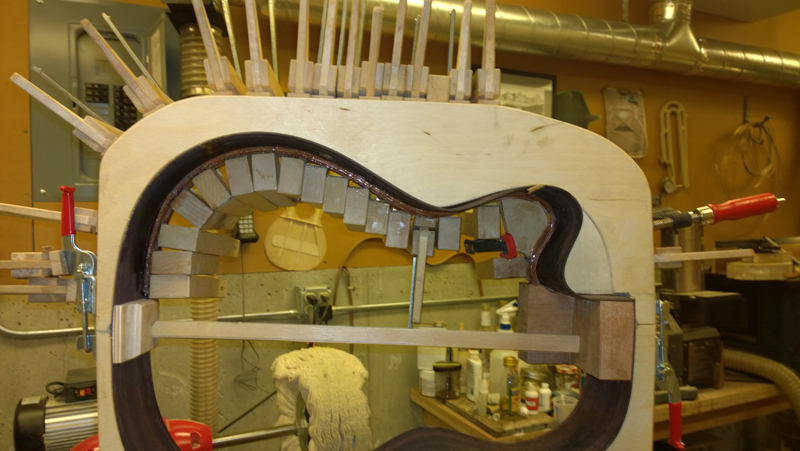

I profiled the two end blocks to the curve of the top and bottom and started to assemble the rims. It takes a bunch of carefully placed clamps to get the heel block in.

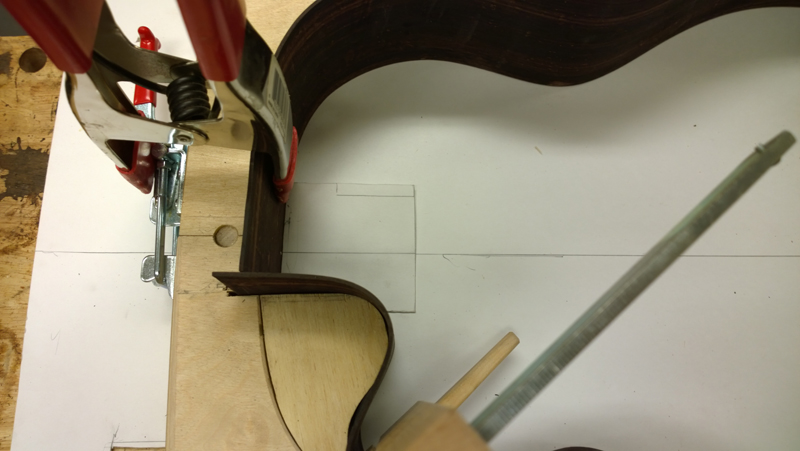

I used the rims them self to profile the bottom of the tail block.

A few clamps to glue the block to the rims.

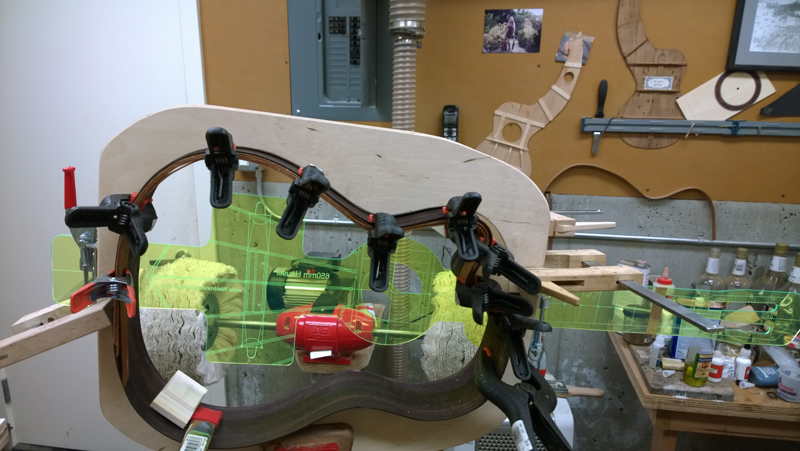

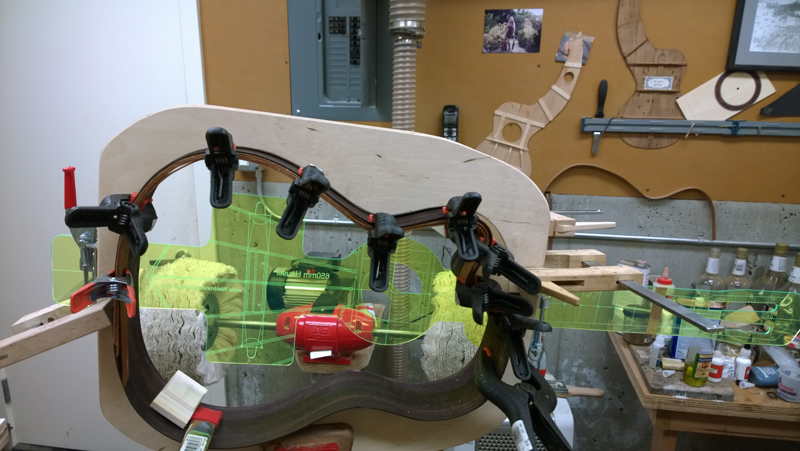

I used the outside mold as the form to laminate and glue on the cutaway top linings. I built a very accurate clamping caul for the cutaway section. When I saw how well that clamped I added some strips to force the apex in a bit more. To give me a bit of open time so I was not in a panic during clamping I used fish glue.

I used a couple small clamps to square the strips together as I worked at clamping the strips to themselves and the rims.

I used a bunch of clamps to really assure that the linings were properly laminated.

I will let this set until tomorrow to give the fish glue the time it needs.