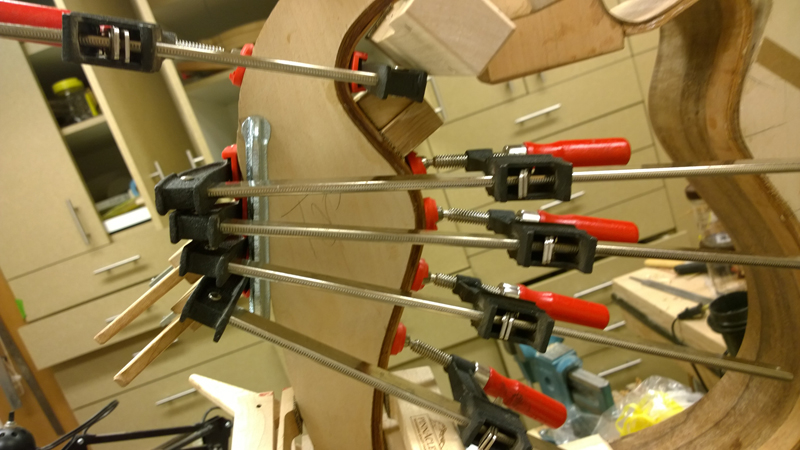

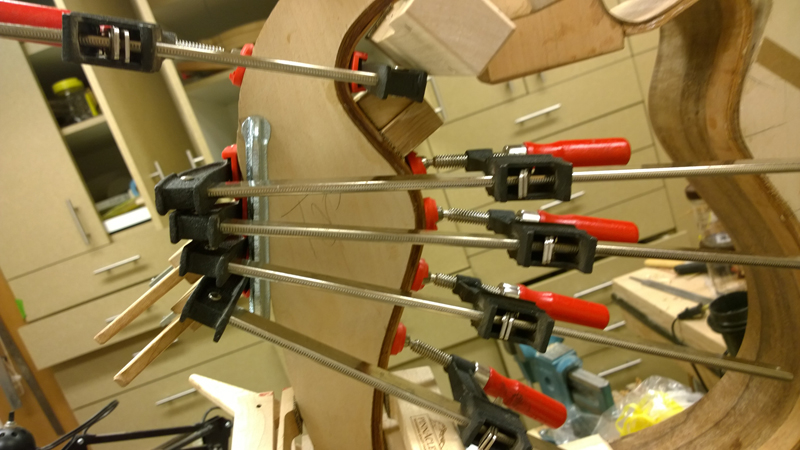

"Here a clamp, there a clamp, everywhere a clamp clamp"!

Wow, that did take a lot of clamps, and John, clean up that messy shop! :>)

This is quite the project. So is this fretboard extension going to screw down?

Kevin

continuing build thread for Gore Medium body SS

-

Kevin in California

- Posts: 2817

- Joined: Mon Dec 19, 2011 4:19 pm

-

John Parchem

- Posts: 2754

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

yes there will be a neck extension under the fret board extension. I will route a cavity in the block that you see to accept the extension. Sort of like an electric guitar. Trevor actually describes it as an electric guitar neck joint with a heel. There will be two holes in the extension on the block for bolts. The neck extension will have two t-nuts to accept the bolts. There will be pictures soon. There will also be the standard mortise and tenon with two bolts. So the neck can bolt on and off. Also nearly the entire fret board is supported.Kevin in California wrote:"Here a clamp, there a clamp, everywhere a clamp clamp"!

Wow, that did take a lot of clamps, and John, clean up that messy shop! :>)

This is quite the project. So is this fretboard extension going to screw down?

Kevin

Re: continuing build thread for Gore Medium body SS

Sounds very similar to the Taylor neck joint. Theirs has a mortise that accepts the entire heel profile.

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

-

John Parchem

- Posts: 2754

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

The epoxying of the neck block went OK. Everything seemed to be in the right place and glued down

Not have a special form for gluing making laminated linings together and I decided, as suggested in the book to both glue the laminate together at the same time as gluing them to the rims. Before starting I knew that there going to be the need for a few clamps and as things slides around I would need some time to get everything clamped tight and the bindings at least close to level, I decided to use fish glue. It is great stuff but it likes to stay clamped for 12 hours.

In the first picture you can see that I made a caul for inside of the cutaway. As it was not perfectly bent some clamping force was required. In this picture if you look toward the center I used really cute 4" hand screw clamps to square up the stack of linings as I clamped along the stack.

Ultimatly I am glad I had the time with the fish glue as there was some jockeying of clamps before I was happy. I started with the cutaway side. the neck day I did the non cutaway side.

The glue up went well on both sides. The rims are really stiff with the linings installed. A noticeable difference from regular kerfed linings.

Using a block plane and my radius dishes I profiled the back and top rims. First the top, and then I measured the heieght I wanted at the center of the blocks and used my poster board rim profiles to draw a rough profile where the back rims would be. When I started my neck block was a bit over 10 mm long, so I actually took the body to the band saw to cut the back profile a bit closer.

Now I need to put the kerfed linings on the back rims, make and install the side reinforcement strips and make and install the side weight mount.

Not have a special form for gluing making laminated linings together and I decided, as suggested in the book to both glue the laminate together at the same time as gluing them to the rims. Before starting I knew that there going to be the need for a few clamps and as things slides around I would need some time to get everything clamped tight and the bindings at least close to level, I decided to use fish glue. It is great stuff but it likes to stay clamped for 12 hours.

In the first picture you can see that I made a caul for inside of the cutaway. As it was not perfectly bent some clamping force was required. In this picture if you look toward the center I used really cute 4" hand screw clamps to square up the stack of linings as I clamped along the stack.

Ultimatly I am glad I had the time with the fish glue as there was some jockeying of clamps before I was happy. I started with the cutaway side. the neck day I did the non cutaway side.

The glue up went well on both sides. The rims are really stiff with the linings installed. A noticeable difference from regular kerfed linings.

Using a block plane and my radius dishes I profiled the back and top rims. First the top, and then I measured the heieght I wanted at the center of the blocks and used my poster board rim profiles to draw a rough profile where the back rims would be. When I started my neck block was a bit over 10 mm long, so I actually took the body to the band saw to cut the back profile a bit closer.

Now I need to put the kerfed linings on the back rims, make and install the side reinforcement strips and make and install the side weight mount.

Re: continuing build thread for Gore Medium body SS

I like the idea of limiting/tapering the ends of the tail block to width of the ribbon lining. Some factories are now doing this (including Martin on some model) makes it a tad easier to put the contour on the back side of the rim.

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

-

Beth Mayer

- Posts: 11

- Joined: Fri Nov 02, 2012 11:01 am

Re: continuing build thread for Gore Medium body SS

Trevor recommends this in his Build book because he said it gives a continuous width gluing surface which prevents a ripple effect that happens when the tail block is left thick at the glue surface level. I'm going to try it on my future builds.ken cierp wrote:I like the idea of limiting/tapering the ends of the tail block to width of the ribbon lining. Some factories are now doing this (including Martin on some model) makes it a tad easier to put the contour on the back side of the rim.

Re: continuing build thread for Gore Medium body SS

Well you got me there --- what is the ripple effect? And what is the problematic issue with the millions of guitars constructed in the conventional manner?

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html