Re: 12 String SS Falcate braced Ziricote\spruce guitar.

Posted: Fri Jun 03, 2016 12:23 am

I like carving the neck but I tend to be nervous about the preparation I do to get ready to start carving. I need to take the big router to make the mortise. I switched to the table saw to make the tenon.

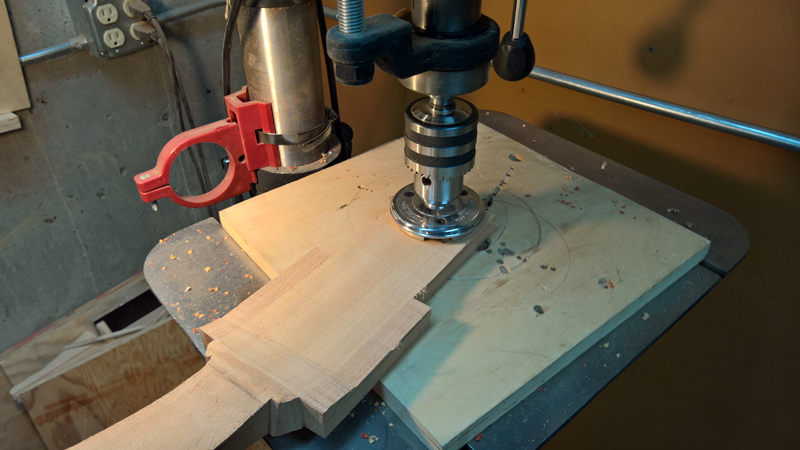

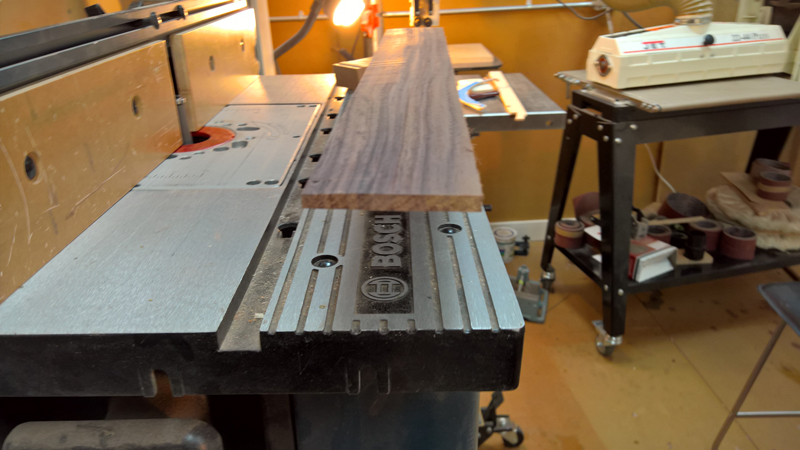

I use a 3/8th bit and my router table to route the truss rod channel in the neck.

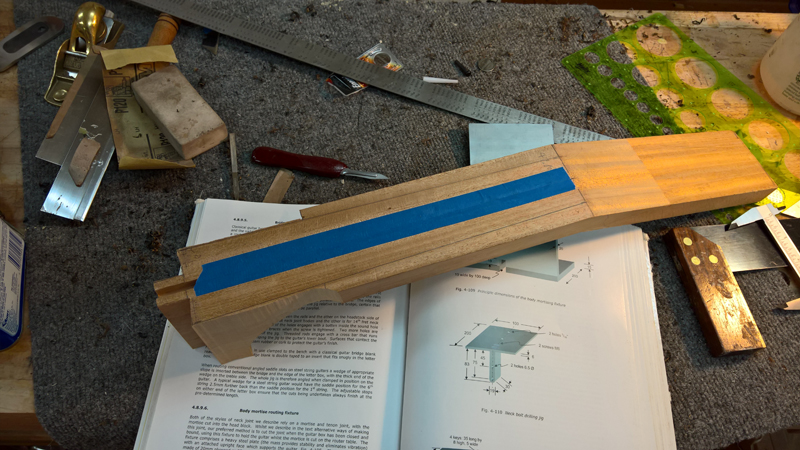

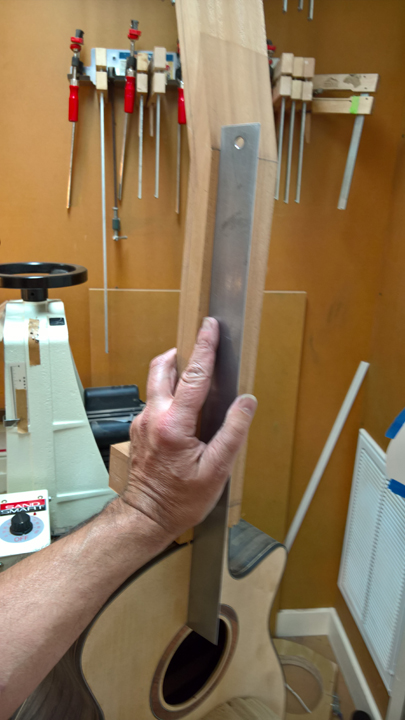

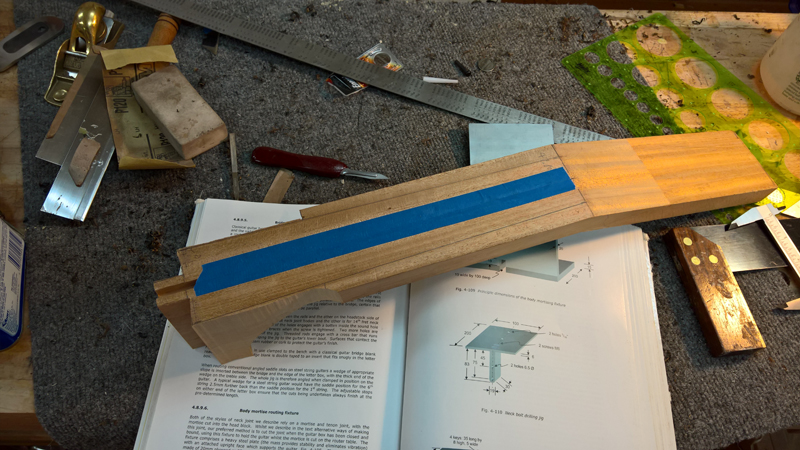

Before making the tenon I sliced the angle I though the neck shoud have on the bottom of the neck blank to and checked the it was correct. I will use the same angle to cut out the mortise.

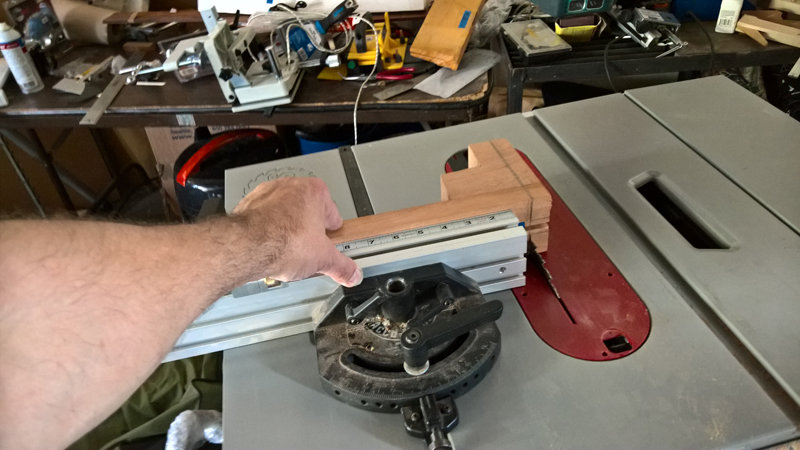

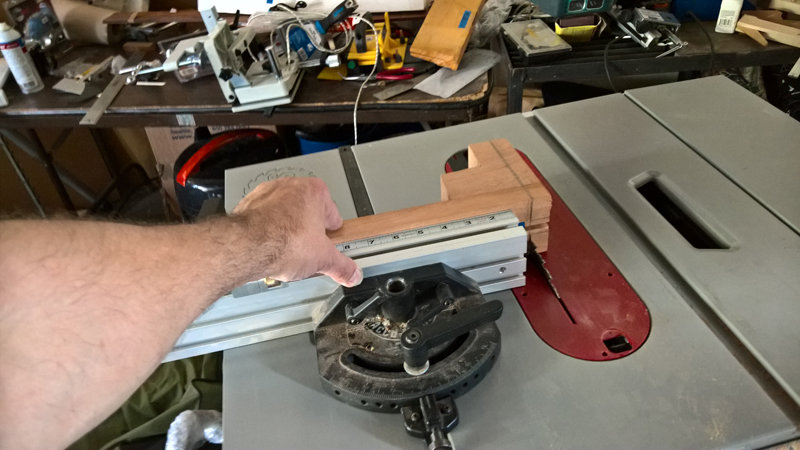

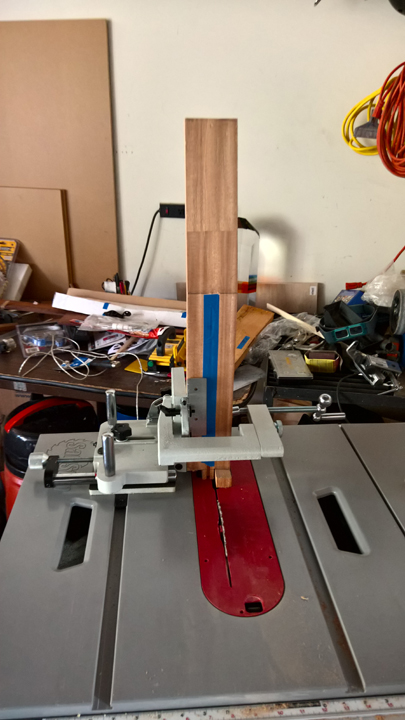

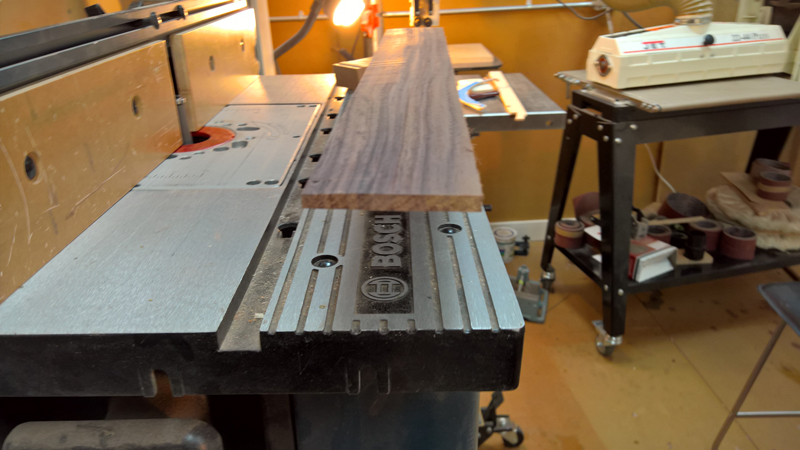

This is my new way of making the bolt on tenon using the table saw. I used a miter gauge to set the angle of the cheeks and I have the blade tilted at 5 degrees to make it easier to fit to the body.

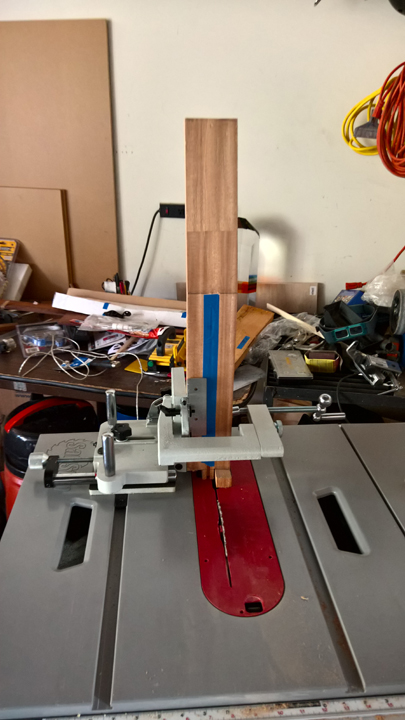

I have a new grizzly tenoning jig to cut the tenon out. The jig actually allowed me to turn the neck back to front without changing a setting so for once I got a perfectly centered tenon.

It came out OK.

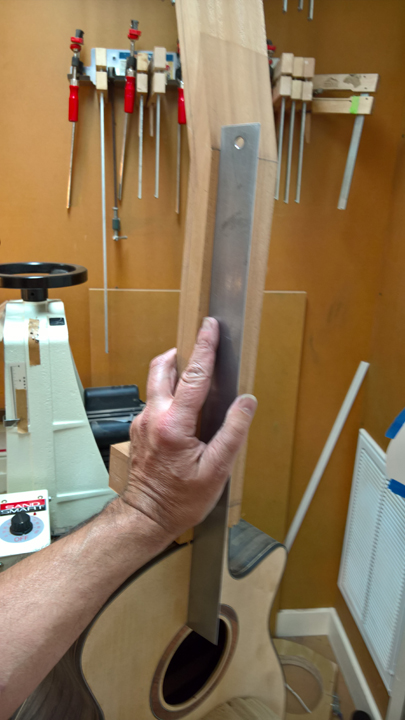

I have a luthiers tool body clamp and template. Not shown they have a Plexiglas template that allowed me to properly center the body clamp. I use a big router with a template follower and used a half inch down cut bit. The mortise is 3/4" deep.

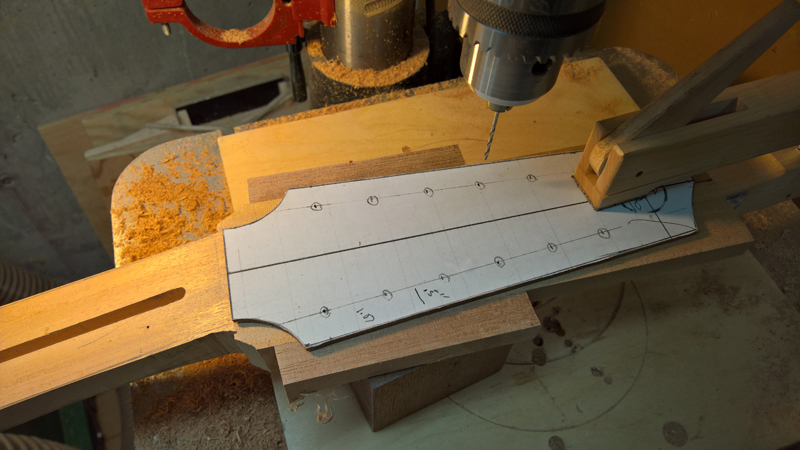

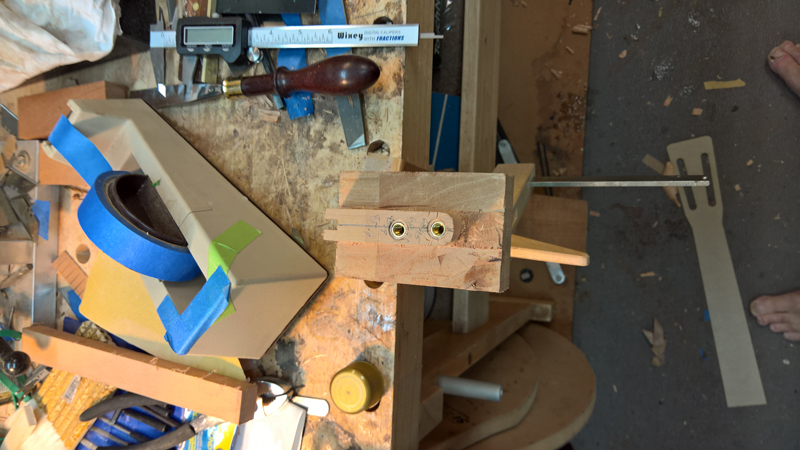

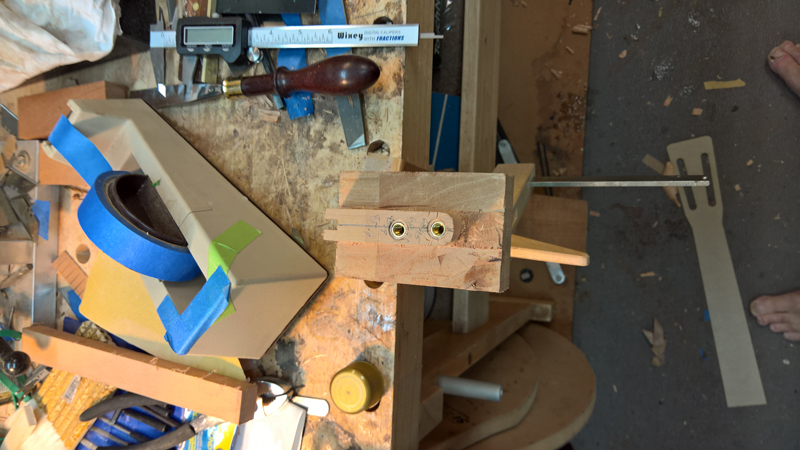

I used my pillar drill (or drill press) to drill a couple of 5/8 holes for the brass inserts I use. I use to use a hand drill but I got tired of crooked holes. I used hole centers to mark where the bolt holes needed to go on the neck block and then installed the brass inserts. You can see why I need to mark the holes as I was off center on one. :(

.

.

.

.

.

.

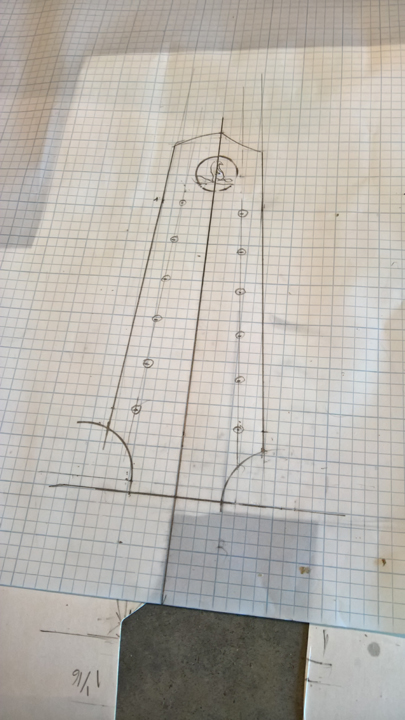

Before going farther I really need to a fret board. The neck will be a bolt on bolt off. Before I drill the pocket for the the neck extension block I wanted the neck centered and at the correct angle.

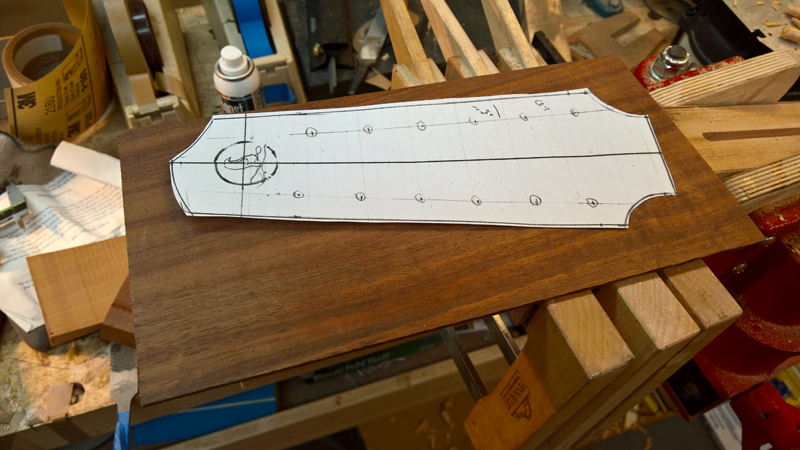

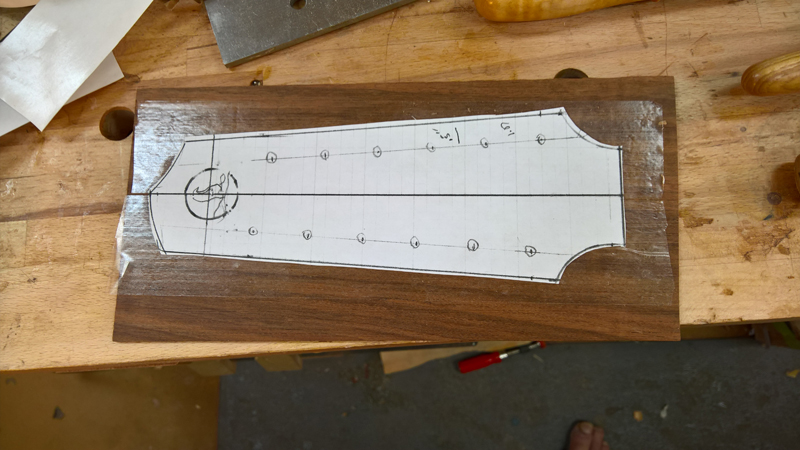

This is my forth guitar that I used the fret board radius router bits I purchased from http://sje-tools.com/. They really work well and save me from a bunch of planing and sanding. THis router bit gets me 95% there. I just clean the fret board with a radius block.

While I was at it I sawed the fret slots and use a band saw and a plane to taper the fret board

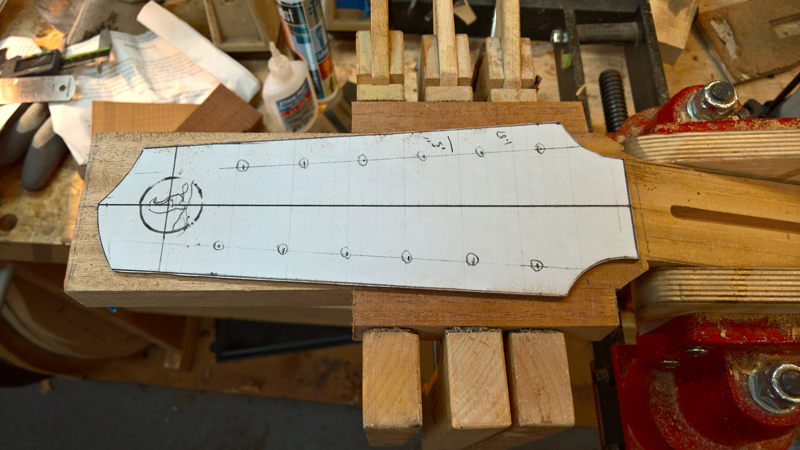

I trimmed the lower portion of the neck to match the fret board with the band saw and a spoke shave. With the neck to body join properly dimension. I went through the normal procedure to correct a bit of side to side tilt and fine tuned the neck angle.

.

.

.

.

.

.

With the neck properly aligned and bolted on I used my jig to route out the pocket in both the neck block and the neck itself. I did not take a picture but here are a couple from my last guitar.

And this guitar

Currently I have the extension clamped into the neck while the glue cures.

I use a 3/8th bit and my router table to route the truss rod channel in the neck.

Before making the tenon I sliced the angle I though the neck shoud have on the bottom of the neck blank to and checked the it was correct. I will use the same angle to cut out the mortise.

This is my new way of making the bolt on tenon using the table saw. I used a miter gauge to set the angle of the cheeks and I have the blade tilted at 5 degrees to make it easier to fit to the body.

I have a new grizzly tenoning jig to cut the tenon out. The jig actually allowed me to turn the neck back to front without changing a setting so for once I got a perfectly centered tenon.

It came out OK.

I have a luthiers tool body clamp and template. Not shown they have a Plexiglas template that allowed me to properly center the body clamp. I use a big router with a template follower and used a half inch down cut bit. The mortise is 3/4" deep.

I used my pillar drill (or drill press) to drill a couple of 5/8 holes for the brass inserts I use. I use to use a hand drill but I got tired of crooked holes. I used hole centers to mark where the bolt holes needed to go on the neck block and then installed the brass inserts. You can see why I need to mark the holes as I was off center on one. :(

.

. .

. .

.Before going farther I really need to a fret board. The neck will be a bolt on bolt off. Before I drill the pocket for the the neck extension block I wanted the neck centered and at the correct angle.

This is my forth guitar that I used the fret board radius router bits I purchased from http://sje-tools.com/. They really work well and save me from a bunch of planing and sanding. THis router bit gets me 95% there. I just clean the fret board with a radius block.

While I was at it I sawed the fret slots and use a band saw and a plane to taper the fret board

I trimmed the lower portion of the neck to match the fret board with the band saw and a spoke shave. With the neck to body join properly dimension. I went through the normal procedure to correct a bit of side to side tilt and fine tuned the neck angle.

.

. .

. .

.With the neck properly aligned and bolted on I used my jig to route out the pocket in both the neck block and the neck itself. I did not take a picture but here are a couple from my last guitar.

And this guitar

Currently I have the extension clamped into the neck while the glue cures.