I wonder if, in the interest of saving top mass, carving the braces into an "A" shape, with the CF being the size of the top of the "A" would be of any help as the top is voiced? Seems like the CF on the bottom and the top of the braces constitutes the horizontal parts of an "I-beam" and therefore the loss of some of the separating material would have little effect on their stiffening aspect.

I realize Trevor does not do this in his own building. But as the guy in the video said, some improvements are the result of numerous otherwise "undetectable" changes. Then again, they may simply be in the ear of the beholder. Like pointy scallops.

continuing build thread for Gore Medium body SS

-

John Parchem

- Posts: 2754

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

John Link wrote:I wonder if, in the interest of saving top mass, carving the braces into an "A" shape, with the CF being the size of the top of the "A" would be of any help as the top is voiced? Seems like the CF on the bottom and the top of the braces constitutes the horizontal parts of an "I-beam" and therefore the loss of some of the separating material would have little effect on their stiffening aspect.

I realize Trevor does not do this in his own building. But as the guy in the video said, some improvements are the result of numerous otherwise "undetectable" changes. Then again, they may simply be in the ear of the beholder. Like pointy scallops.

Interesting thought, I am sure that there would be little loss of stiffness and some loss of weight. I can say though on this first one getting the fiber down on top of the flat braces was hard enough without having it slide down the A.

-

John Parchem

- Posts: 2754

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

Here is the completed top bracing, now on to building a guitar to use it.

Re: continuing build thread for Gore Medium body SS

I was thinking of carving the sides back after the CF was applied. The bracing system itself is the only one I know of that places the bridge at the center of its structure. Visually, it appears to facilitate the unified motion of the top usually described as the monopole.

John

-

John Parchem

- Posts: 2754

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

Yes that does make sense. Looking at the brace patterning I agree I like the symmetry radiating out from the bridge in the lower bout. The symmetry is also reflected in how the braces thin toward the edges. While my version is a bit messy for the most part I am right on the plan with regard to height, width and tapering of the braces.John Link wrote:I was thinking of carving the sides back after the CF was applied. The bracing system itself is the only one I know of that places the bridge at the center of its structure. Visually, it appears to facilitate the unified motion of the top usually described as the monopole.

I am going to work on the rims this week and maybe the back this coming weekend.

-

John Parchem

- Posts: 2754

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

I had to slow down a bit. The last few days I had to keep peace in the household come up out of the shop and installed a poly-carbonate roof on our all steel pergola in my wife's garden. :| She is a landscape designer by trade, if I am not careful she will have me working full time.

I did find one reward to working outside, a small batch of morel mushrooms for a tasty snack.

I finally made it back in the shop Friday and got the sides bent. There is a pretty tight bend for the cutaway.

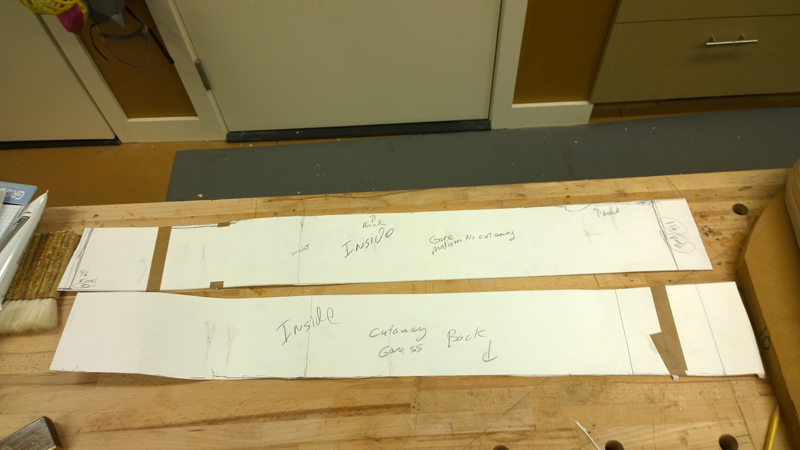

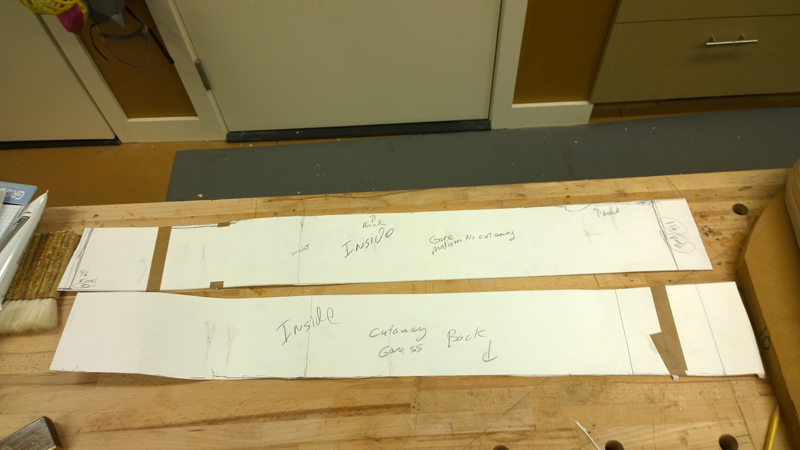

First I had a bit of prep work. I used a 10' radius dish I am using for the back radius to make an accurate template of the profiled sides. I put a strip of poster board into the mold on top of the radius dish and used a pencil in a small bit of wood to trace the curve of the radius board on to the poster board. from the neck and tail side of the curve, I measured up the depth of the body, plus a 10 mm, drew a straight line for the top and cut out the profiles. I leave the top flat has I will use it as a reference when I am first setting the rims in the mold.

I cut out the side profiles and then used my drum sander to thickness both sides to 2.2 mm. I used a scraper to thin the cutoff side from above the waist to 1.9 mm so I would have a chance of bending them.

I took extra care was to keep track of the top and outside of each side so that I would not bend the asymmetrical sides for a left handed guitar. I must have checked this 10 times. I did once end up with a sides for a left handed harp ukulele.

As the profile for this guitar has different proportions for the upper and lower bouts I found I had to drill a new set of holes in my bender to put the cutaway press in the correct space.

Also notice the band clamp. The last time I did a Florentine cutaway the spring back on the sides was scary. This time as I loosened the cutaway press I tightened the clamp holding down the lower sheet of spring steel.

.

.

.

.

All and all it tuned out ok. I had a bit of fibers tearing away on the inside. I used a bit of CA to fix.

I did find one reward to working outside, a small batch of morel mushrooms for a tasty snack.

I finally made it back in the shop Friday and got the sides bent. There is a pretty tight bend for the cutaway.

First I had a bit of prep work. I used a 10' radius dish I am using for the back radius to make an accurate template of the profiled sides. I put a strip of poster board into the mold on top of the radius dish and used a pencil in a small bit of wood to trace the curve of the radius board on to the poster board. from the neck and tail side of the curve, I measured up the depth of the body, plus a 10 mm, drew a straight line for the top and cut out the profiles. I leave the top flat has I will use it as a reference when I am first setting the rims in the mold.

I cut out the side profiles and then used my drum sander to thickness both sides to 2.2 mm. I used a scraper to thin the cutoff side from above the waist to 1.9 mm so I would have a chance of bending them.

I took extra care was to keep track of the top and outside of each side so that I would not bend the asymmetrical sides for a left handed guitar. I must have checked this 10 times. I did once end up with a sides for a left handed harp ukulele.

As the profile for this guitar has different proportions for the upper and lower bouts I found I had to drill a new set of holes in my bender to put the cutaway press in the correct space.

Also notice the band clamp. The last time I did a Florentine cutaway the spring back on the sides was scary. This time as I loosened the cutaway press I tightened the clamp holding down the lower sheet of spring steel.

.

. .

.All and all it tuned out ok. I had a bit of fibers tearing away on the inside. I used a bit of CA to fix.

-

John Parchem

- Posts: 2754

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

Amazingly, the guitar rims fits in the mold. I think I will find a very bendable wood for the bindings. The last one I did I used ebony, it only took 10 or so strips to bend 2 without cracking.