Lonnie, The fish glue is nice as it has some of the repair qualities of HHG but has a long open time, and two year shell life. I mainly bought it because I am going to be making traditional classical guitar rosettes and it is a good glue for that.

As for the clamps, it really depends on the system you are using. Did you buy one of Ken's mega molds? I believe that the mold make it easy to use rubber bands as clamps.

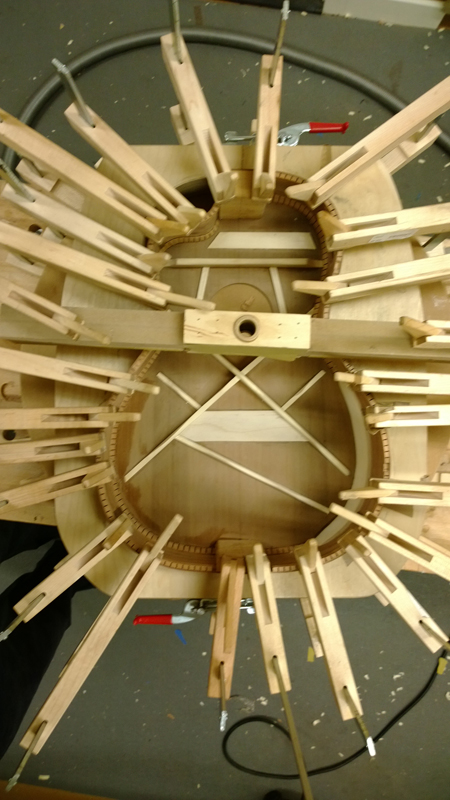

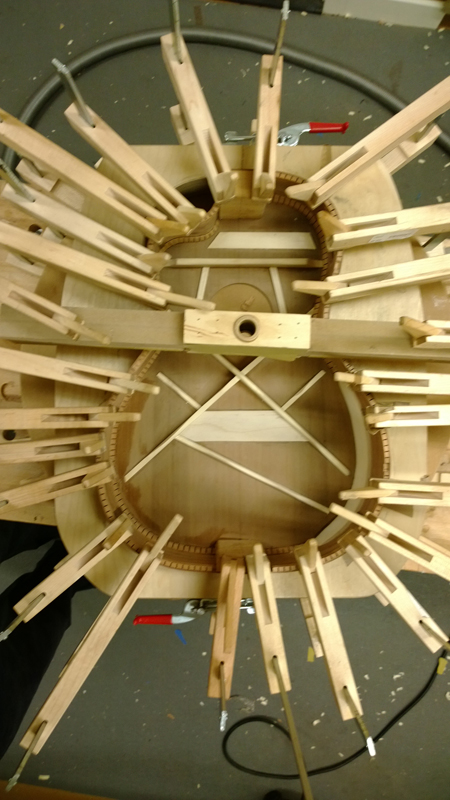

The following picture illustrates what is different about Kent Everett's bevel procedure than others that I had looked at before starting. The purfling and the binding edge for the top and rims are set before the guitar is assembled. My fear of the bevel was how to get a clean edge on the purflings\top or the purfling\rim hand cutting on the finished body. Setting this up before assembly allowed me to use all sorts of tools to get a clean edge.

Once I start binding I will glue the top purfling in the bevel backed by the top cutout from cutting the top. On the binding side I will thin the binding height where I need to follow the bevel.

Once the guitar is bound, I can comeback, with rasps and or sanding to shape the bevel. Then I will have a smooth surface to glue a piece of veneer. The veneer can be loosely cut as I can trim and sand back the over hang and it should blend in to the thinned binding on the rim and can blend into the top purfling.

Although I am not using a purfling on the rims, this method would have allowed me to do that as I am bending the binding into the bevel.

To make life a little easier I am using ebony bindings and ebony veneer.

We shall see.