Binding of the headstock.

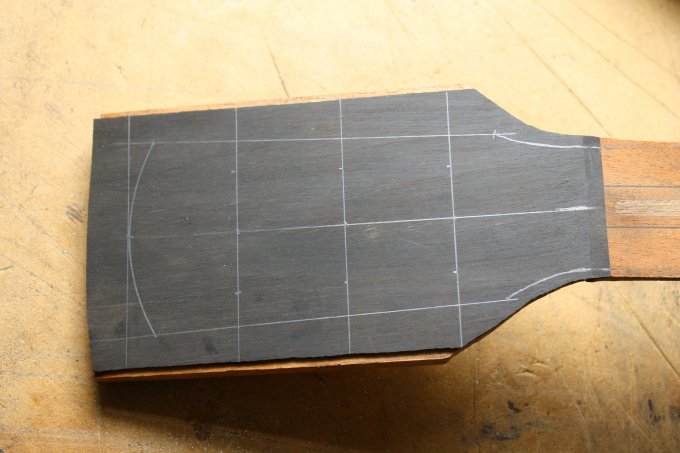

First make the perimeter of the headstock to its final dimensions. 'cause when the binding is on, you can only take off tiny bits. Then with the dremel the slot all around was made.

Crucial imo is the allignment with the fretboardbinding. That looks best.

I glue them with CA. It has a minimum waiting time. I start at the topside with oversized binding. Then, as with the bodybinding I take off the excess and miter the corners with a scalpel. Then work down to the fingerboardside.

If you work slow, with some dryfitting, you can make it almost perfect in line.

Plane off the excess and make thing flush with a scraperblade. be careful not to hook into the buttjoints of the bindings.

Yes with maple they always show. I hate that! Why do people always want curly maple for a binding. Please choose a nasty grayish/brownish wood for that, and I make you an immaculate edge. But here maple it is...........

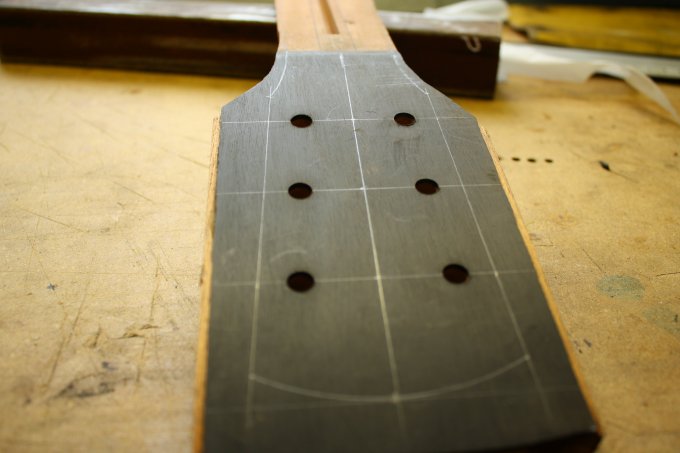

So when all maple-discontent is gone, the fingerboard is glued.

-trussrod in place with a few drops of gelly photoglue. Veneer on top. Be shure the topside of the neck is flush with that.

-Little nails through the 1st and 12th fretslot into the neckwood for alligment. That way the fingerboard cannot slip out of position during glueing.

-I still use titebond. I did use epoxy before, but found that even a bit too much glue wasn't squeezed out enough and leaving a too thick visable glueline. I know lots of us like epoxy for this, but this is how I do it.

-Also I do not clamp with a flat caul like many of us, but still use my firsttimer innertube. Works for me. Next time I tell you if the fingerboard is not twisted of curved. Cause that would be the reason not to rubberband the thing.