Construction:

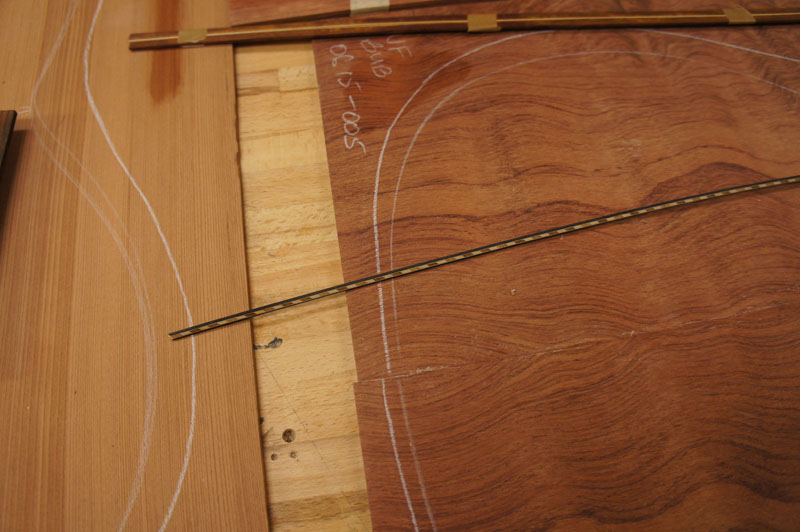

I had no issues at all bending the pre profiled sides on a fox style bender with a heat blanket. I was very happy as the sides once trimmed to size fit perfectly in the molds without needing to push it in place with spreaders. I am taking care to place the bend exactly where I want it so the bend matches the profile I cut also the if the sides are book matched I can control the match.

I also roughed out a neck blank on my band saw. I use a smoothing plane to square the service of the fret board surface and the peg head surface. As you can see in the pictures I cut a 1/2" channel for the truss rod and then epoxy in two .125 * 3/8" carbon fiber rods for neck reinforcement. This leaves me with the proper 1/4 channel for the truss rod. I have seen people rout three different slots, but I see no advantage of spreading the carbon fiber rods. The farther they are spread the better chance you have of them showing when the neck is carved. When I epoxy in the carbon fiber I wrap the truss rod in wax paper and push it in the slot to push the carbon fiber rods against the channel. I DO NOT epoxy in the truss rod.

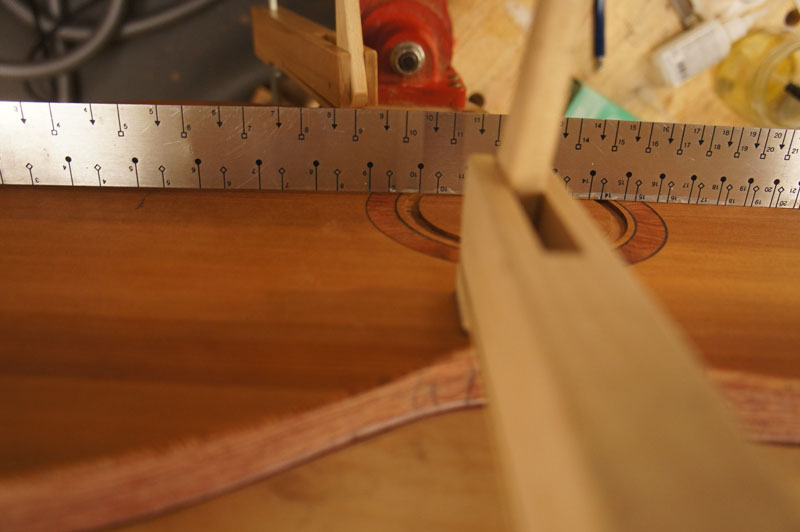

If you are using an outside mold, here is a trick I got form Gore build book. One the end blocks are glued on to the sides and before any profiling take the time to mark out a couple of reference lines.

First adjust the rim on the top side of the guitar (mine top is flat at this time) so that it is straight in the mold, 25mm from the top to the mold all of the way around. Then use the mold as a guide and mark a line all of the way around the guitar. This line is a reference throughout the build process to put the rims back in the mold square. One the rims are sanded to the right profile there are no good other references to be sure that the rims are in the mold square.

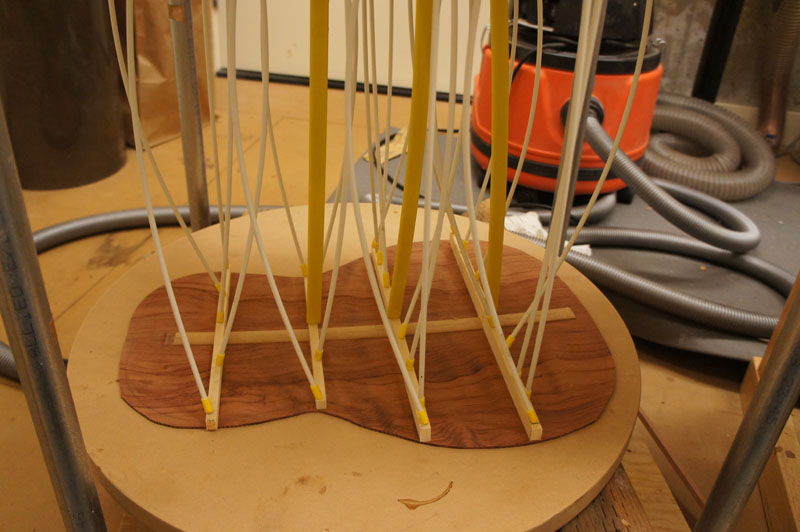

I used a plane to trim the rims on the back to they were very close to the correct profile. I use a 15' radius dish for the back and a 28' dish for the top to sand the profiles I want. I do the top different than Ken to set the angle, but I have found that if I carefully sand a 28" radius on the top I have the correct angle on the top. Before I glue the top on I check the angle to make sure it is correct.

I completely profile the rims before I put the kurfed linings on with the linings just a bit proud. Before gluing on the linings I use a technique that Ken shows on his web site to pre-bend reverse kerfling on the out side of the rims by spraying both sides of the kerfed linings and letting them dry in place.