Hi John

The machines are made by a company called Schertler and are the best tuner I've ever used - not cheap tho!

Have a look here - http://gallery.me.com/schertler#100233& ... &view=grid and here - http://www.schertler-guitars.com/Schert ... UNERS.html

I believe StewMac sells some of their tuners and I've also seen them on ebay - highly recommended.

harp ukulele project - Gluing down the bridge...

-

Bob Matthews

- Posts: 146

- Joined: Mon Dec 19, 2011 8:49 am

- Location: Surrey, England

- Contact:

Re: Starting a harp ukulele

John:

COOL!!! I will love watching your progress on this build!! The only other person I was able to get some tips from, when I was building mine last summer, was Pete ---- I'm sure I'll get some great ideas and tips from you as I watch your build! I recently sold my harp uke to a fellow teacher, who advises our high school's uke club, and so now I need to build another one for myself (this one I don't intend to sell!), so watching your build will be fun, and, I'm sure, a help to me. It's a really fun, challenging project, a bit different from anything else I've built! Will you be posting your progress here, regularly?

Kathy

COOL!!! I will love watching your progress on this build!! The only other person I was able to get some tips from, when I was building mine last summer, was Pete ---- I'm sure I'll get some great ideas and tips from you as I watch your build! I recently sold my harp uke to a fellow teacher, who advises our high school's uke club, and so now I need to build another one for myself (this one I don't intend to sell!), so watching your build will be fun, and, I'm sure, a help to me. It's a really fun, challenging project, a bit different from anything else I've built! Will you be posting your progress here, regularly?

Kathy

Kathy Matsushita

http://theamateurluthier.com

http://theamateurluthier.com

-

John Parchem

- Posts: 2749

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: Starting a harp ukulele

Thanks Kathy,

I tend to post in detail so you will see my progress for good or for bad. I have read through your blog a few times, notice the shape of the form I made so that it fits in the bender. I post progress pretty regularly but as I work full time it is usually on weekend and sometimes life intrudes. Most of my instruments take 4 to six months. I hope to see the progress of yours as you build a second.

John

I tend to post in detail so you will see my progress for good or for bad. I have read through your blog a few times, notice the shape of the form I made so that it fits in the bender. I post progress pretty regularly but as I work full time it is usually on weekend and sometimes life intrudes. Most of my instruments take 4 to six months. I hope to see the progress of yours as you build a second.

John

Re: Starting a harp ukulele

Way cool John!!!

David L

David L

-

John Parchem

- Posts: 2749

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: Starting a harp ukulele

With the bass guitar out of the way and a couple of weekends doing garden work :(. I finally got to get back to the harp ukulele.

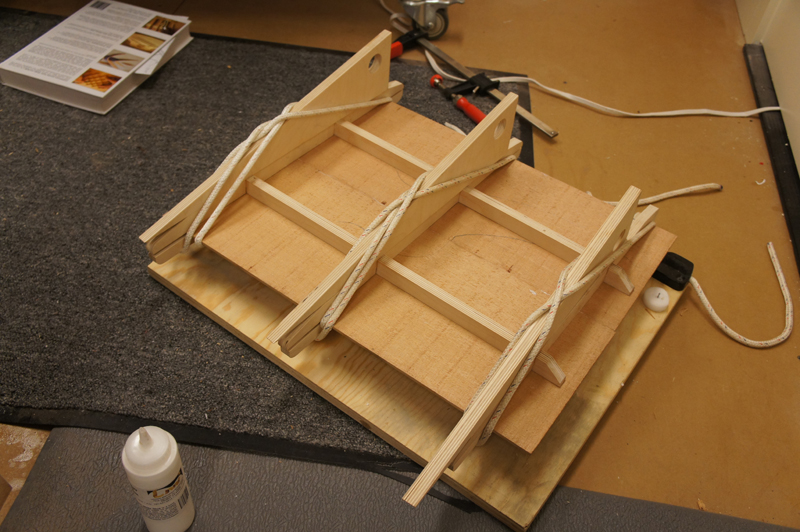

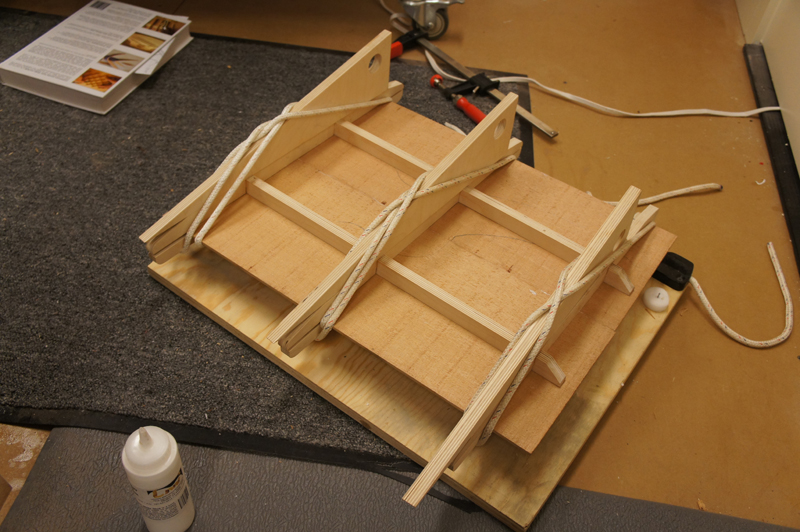

First up I made a shooting board to help when I need to join the top and back plates. I am still learning with the plane. The jointer in the picture worked great for the cedar but had too low of an angle for the koa and tended to tear out some of the more figured areas. I do not have a good bench plane so I finished the koa joint with a strip of sand paper on glass.

I do like using the plate joining jig. Before buying this jig (I know looks pretty easy to make) I tried both the streched tape and clamping it between some nails. This jig is fool proof to assure the plates are both clamped flat and have good clamping force.

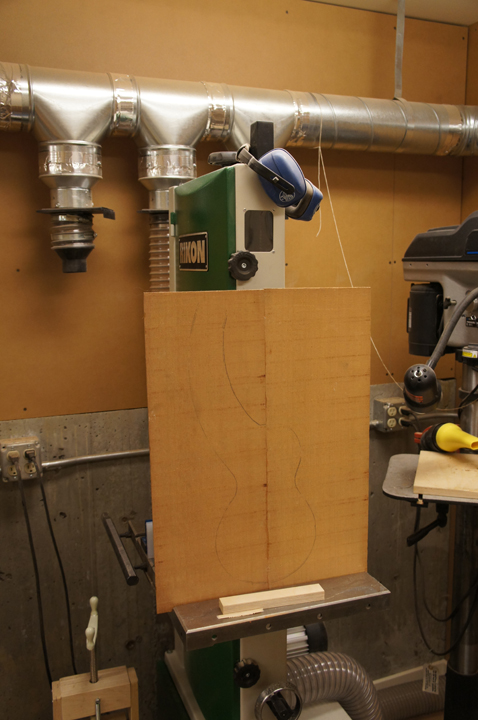

With the back curing, I went to assemble to rims but Oh - oh. Notice how flat the profiled sides are laying; basically top down but the top template is UP. Any one need a koa rim set bent for a left handed harp ukulele?

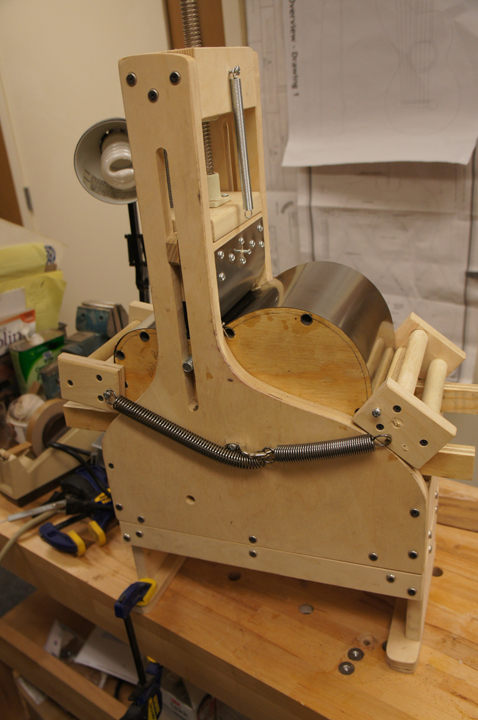

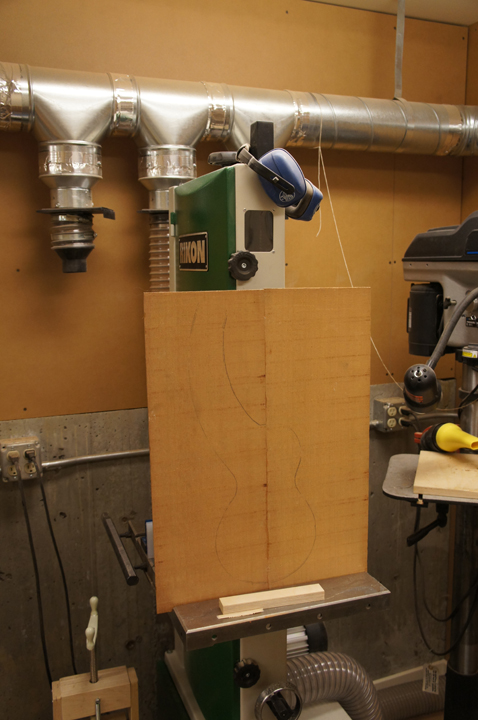

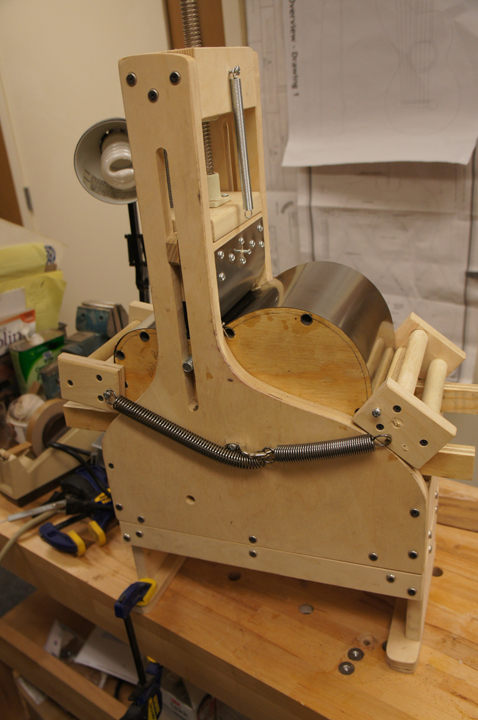

I had another Koa set set :{ and as the next series of photos show I produced a new set of rim components. I rigged up my John Hall bender the best I could to bend the small sides. The harp components I bent on a bending pipe.

The right side miters into the inside harp neck, so I had to build a little jig on my belt sander to sand the 45 degree angle. As you can see in the second photo the angled on the end of the side matches the 45 degree angle on the inside neck block.

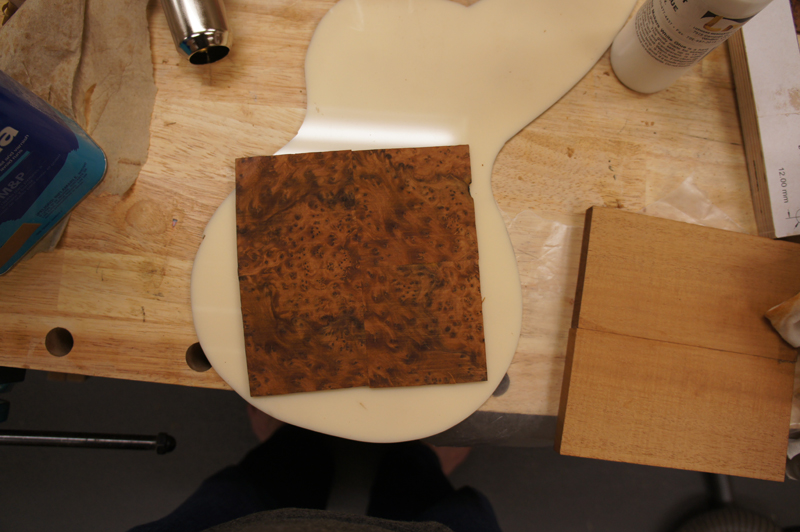

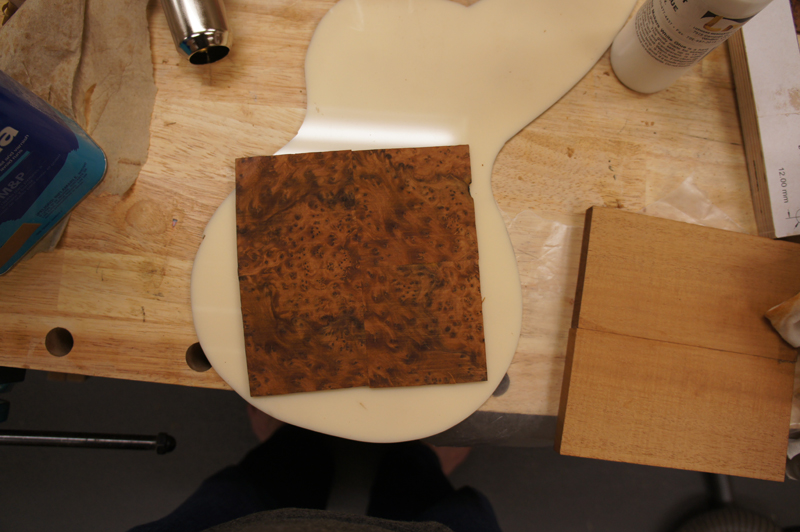

As the next set of picutres showed I worked between gluing the right handed ukulele sides to the neck and tail blocks and preparing the remaining components of the ukulele. I had a block of thuya burl that I resawed of both the bottom and the sides. I joinded the veneers together in various ways to produce a set of veneers for the rosettes, the harp peg board and the uke peg board.

I hope to get more done this weekend I will post again.

First up I made a shooting board to help when I need to join the top and back plates. I am still learning with the plane. The jointer in the picture worked great for the cedar but had too low of an angle for the koa and tended to tear out some of the more figured areas. I do not have a good bench plane so I finished the koa joint with a strip of sand paper on glass.

I do like using the plate joining jig. Before buying this jig (I know looks pretty easy to make) I tried both the streched tape and clamping it between some nails. This jig is fool proof to assure the plates are both clamped flat and have good clamping force.

With the back curing, I went to assemble to rims but Oh - oh. Notice how flat the profiled sides are laying; basically top down but the top template is UP. Any one need a koa rim set bent for a left handed harp ukulele?

I had another Koa set set :{ and as the next series of photos show I produced a new set of rim components. I rigged up my John Hall bender the best I could to bend the small sides. The harp components I bent on a bending pipe.

The right side miters into the inside harp neck, so I had to build a little jig on my belt sander to sand the 45 degree angle. As you can see in the second photo the angled on the end of the side matches the 45 degree angle on the inside neck block.

As the next set of picutres showed I worked between gluing the right handed ukulele sides to the neck and tail blocks and preparing the remaining components of the ukulele. I had a block of thuya burl that I resawed of both the bottom and the sides. I joinded the veneers together in various ways to produce a set of veneers for the rosettes, the harp peg board and the uke peg board.

I hope to get more done this weekend I will post again.

-

John Parchem

- Posts: 2749

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: Starting a harp ukulele

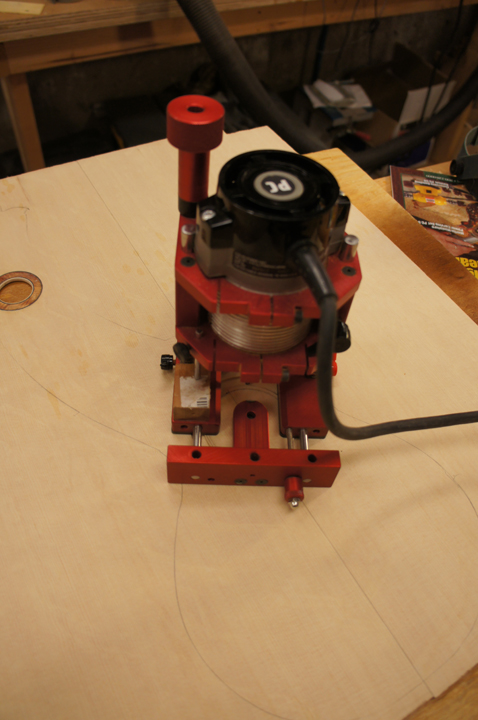

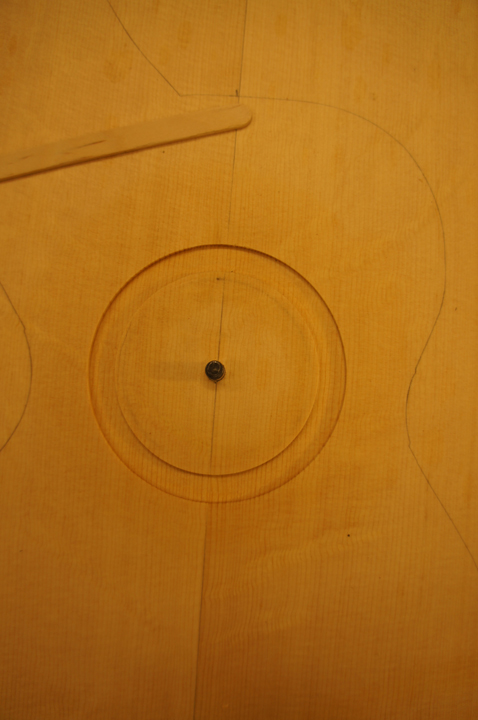

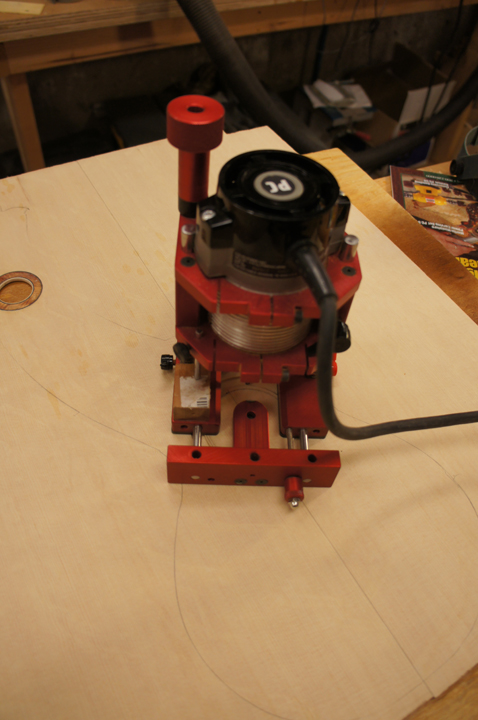

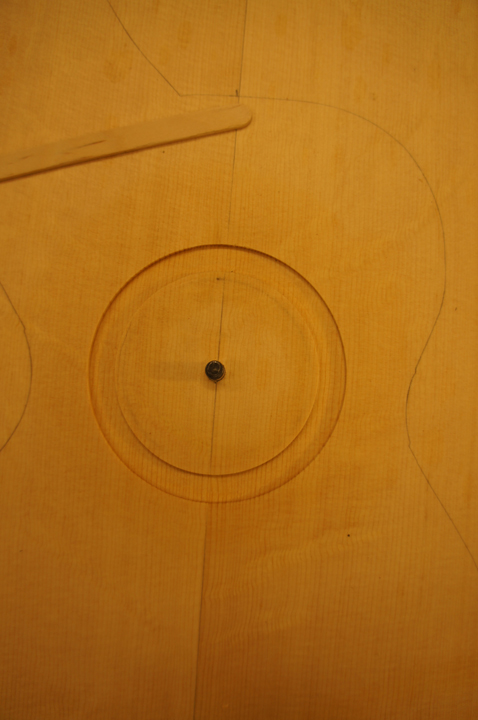

I ended up not liking the color of the Thuya burl on Cedar. They are so close that they clash. So I ended up changing my top to bear claw Sitka spruce with Amboya burl for the rosettes and the peg board veneers. I was able to make and install both rosettes. The little rosette in the harp neck was too small for my PC 310 router with the Bishop Cochran router base, so I had to use the little circle maker that came with my dremel. The little rosette was particularly hard as there is not a fret board that covers up the top of the rosette. Ultimately to get the exact size for the purfling I measured the diameters of the rebates and multiplied them by pi. Then I had the perfect size.

Included in the pictures show the reason I really like a good router in a stable base. You can really see the difference in the quality of the cuts when you compare the two rebates one made by the dremel the other made by the Porter Cable310 abd the Cochran base.

Included in the pictures show the reason I really like a good router in a stable base. You can really see the difference in the quality of the cuts when you compare the two rebates one made by the dremel the other made by the Porter Cable310 abd the Cochran base.

-

John Parchem

- Posts: 2749

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: Starting a harp ukulele

Normally I have a nice tool that allows me to drill the slot head holes and route out slots for my acoustic and classical slot head guitars. I do not have a tool with the right spacing for the ukulele holes or a template narrow enough for the slots. So this one I mostly had to do the old fasion way with a drill and a rasp for the slots. I was able to jury-rig my slot head tool as a drill guide. I had to mark the tuning machine holes and align the tool by eye for each hole. All in all it came out ok. When I was drilling the holes at the end of the slots I blew out the back of the peg head a bit so I sanded it down 2mm and I am gluing on a 2 mm koa back strap veneer. I was considering that any way so I was sort of forced into it.