For routing the side purfling slot, you have to be able to follow the bent side panel and the angled arm bevel. Tricky!! In the video above a huge dremel base is used. That seemed too lumpy to me, so I made a jig for my Dremel base. Since it is very easy to screw things up, I was a bit scared to start the routing. But surprisingly, with patience and a steady hand, it worked perfectly. No sweat after all.

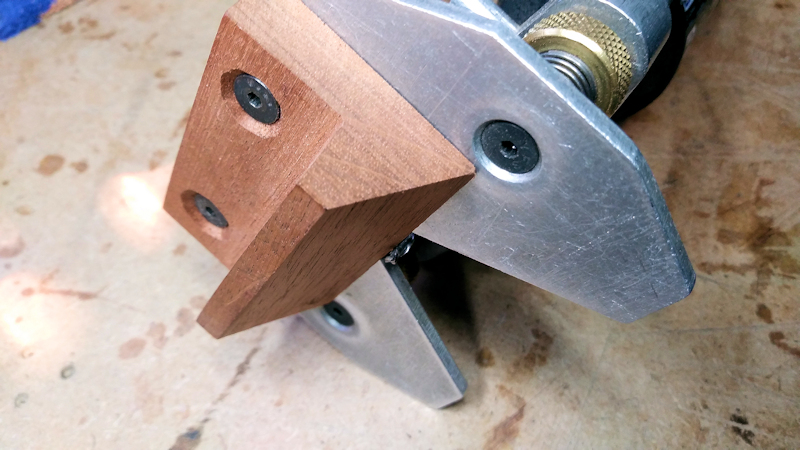

This is how the guide looks:

This is the position how it is used: