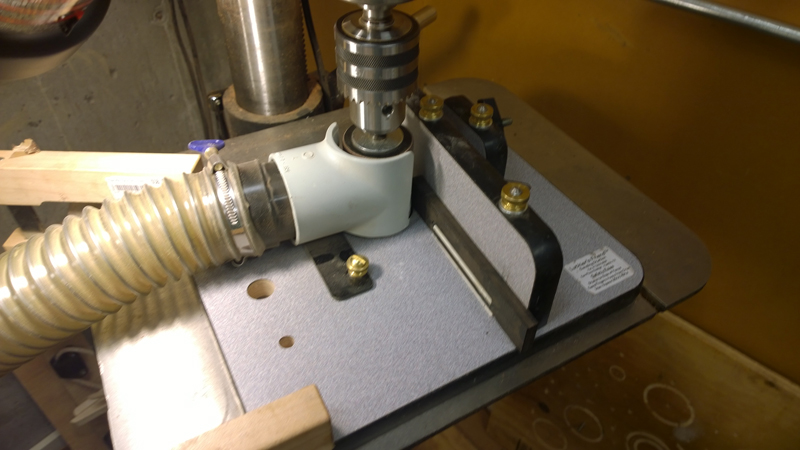

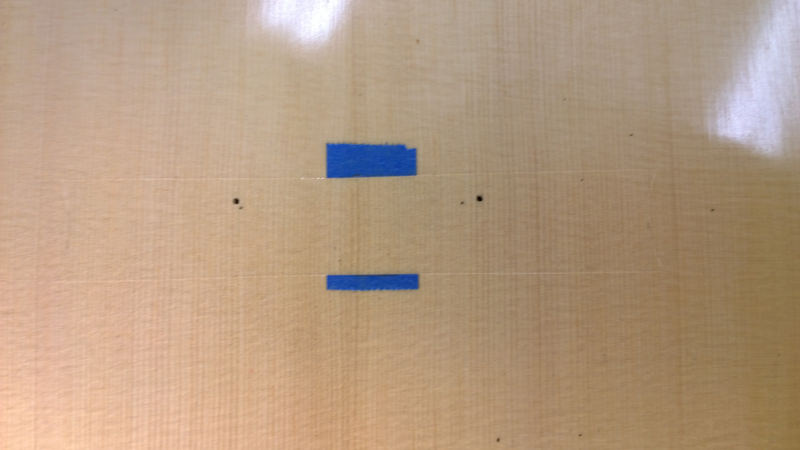

Before finishing the top I looked for glue on the top with a black light. Yup I had some smears in the center and some along the bindings. You can see the bright spot in the lower bout especially along the edges. This is after I though I had the top clean.