Thanks Kevin,

Well I did one step forward, about 8 steps back then forward again.

I closed the box successfully, but when I tapped the closed box I was not happy with the resonance frequency of the top. It ended up about 10 hertz lower than my target. I was pretty sure the guitar would end up close to my first. As I really wanted to hear would the higher pitched top would sound like I ripped off the top with plans to make another.

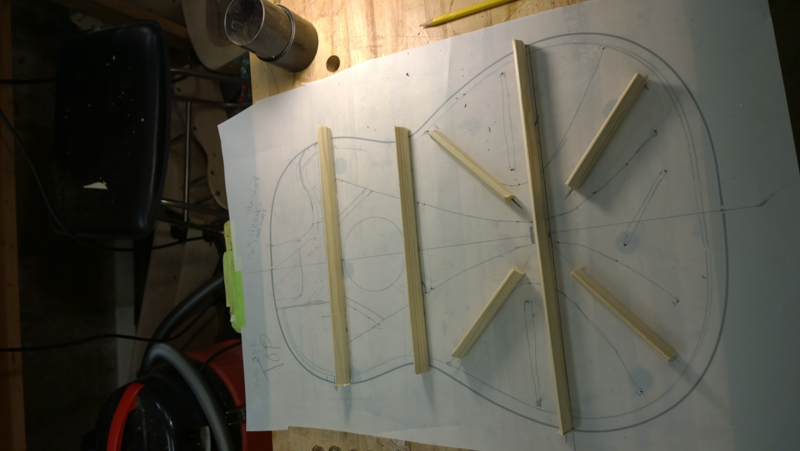

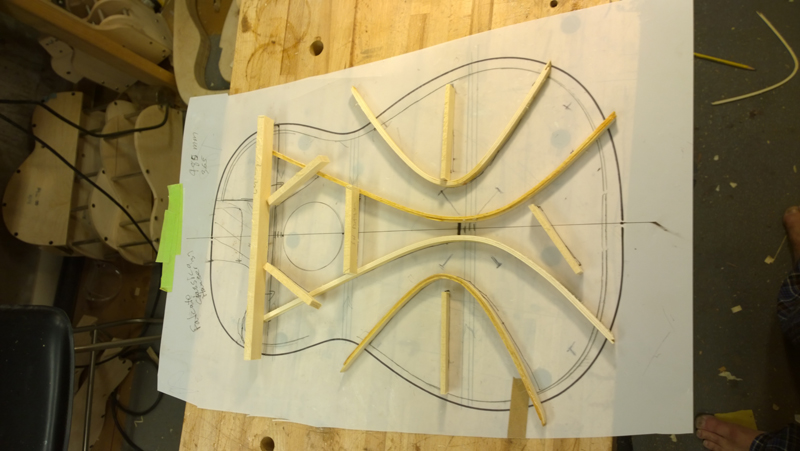

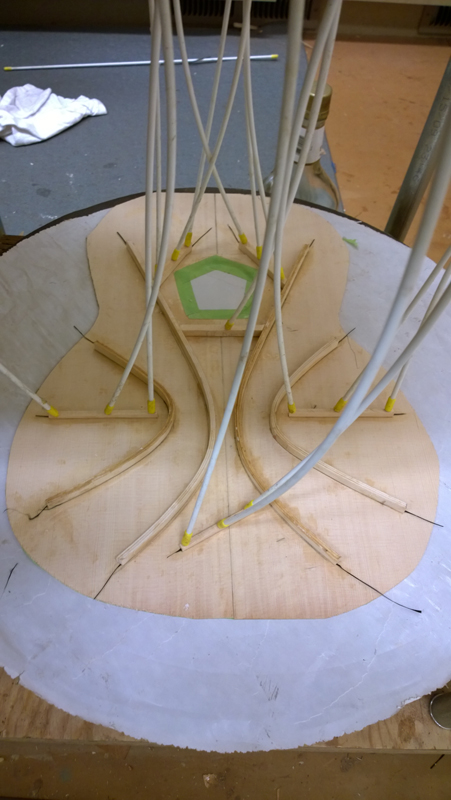

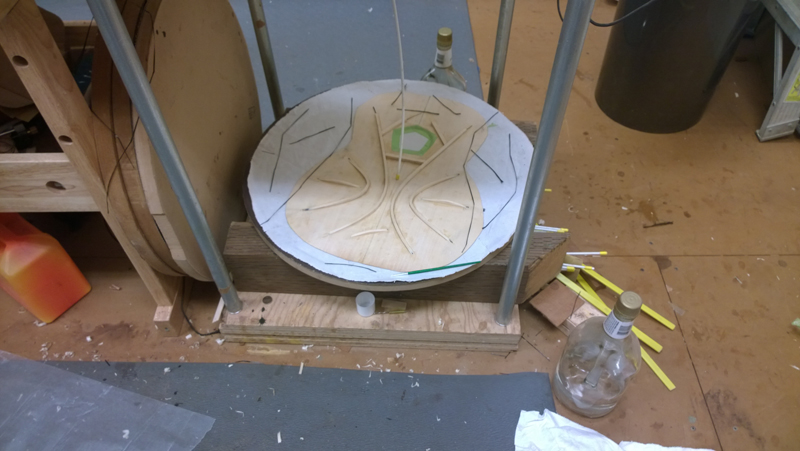

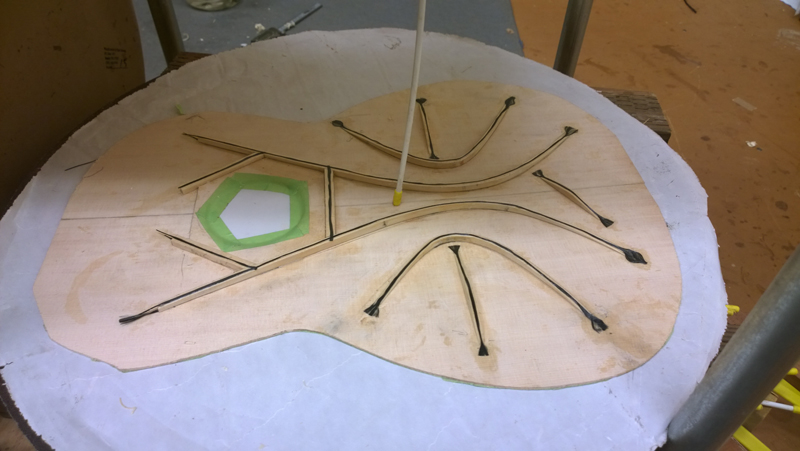

I put the project on the back burner and built a top for an eight string classical guitar with higher falcate braces (8.5mm) and ended up with a top pitched at my target.

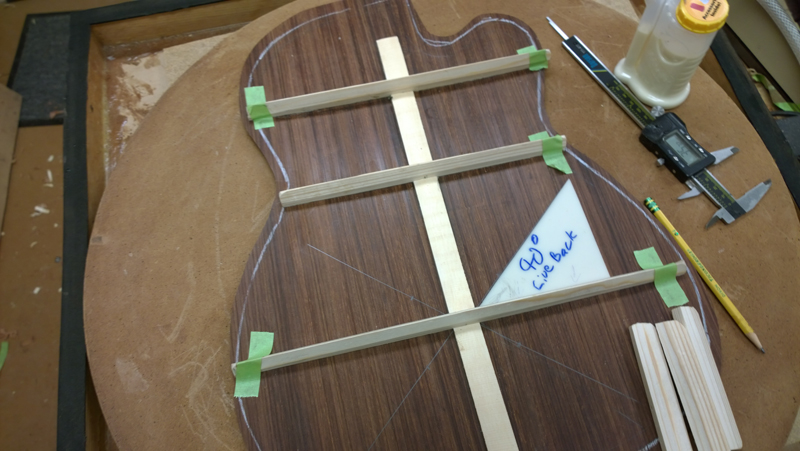

So I am back on this guitar. I made the new top, glued it to the rims and back and got the bindings on ...

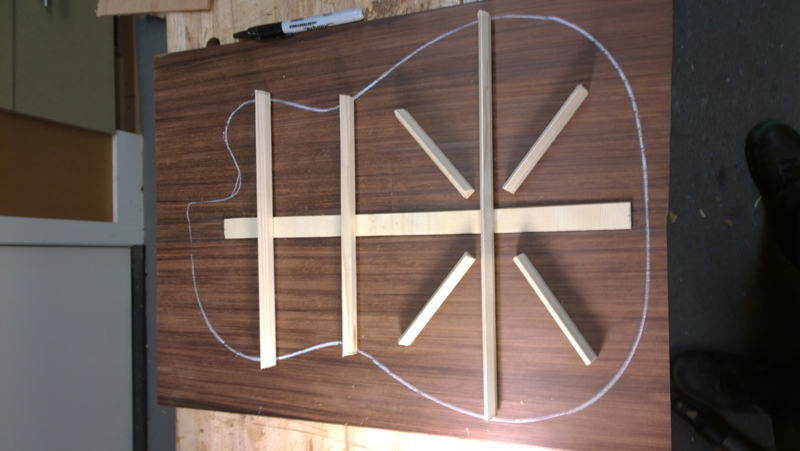

I pulled the first top I was using for this project. I accidentally spilled a bottle of brown stain on the top after the rosette was installed and put it off in disgust. Well the stain came off with light sanding so I had a top with a nice rosette all ready for bracing.

The Australian Blackwood bindings for the cutaway side I bent in the fox bender were cracked so I bent new ones on a hot pipe. A fun job but I did learn a few things about bending on a hot pipe. First after very carefully achieving a perfect bend for the waste and cut away sections be careful. One can still crack a side bending the lower bout. Also I bent these purflings dry. I use a very very hot pipe. I found the wood got plastic much quicker dry, probably as the moisture keeps the wood closer to 220 degrees as it evaporates. Bending by hand I ended up with bindings that fit without having to be forced into the channel shape wise. Also I used a long fabric strip to bind the bindings after I glued them on. I have a 10' radius on the back. The binds fit the profile but they still need to be forced to the back radius. That forcing wants to twist the bindings a bit so they pull away from the channel. Binding them helped close any gaps.

Also I am happy with the resonance frequency of the box now. I think when I finished the guitar it will be very close to my target.