Boy the colors are really poppin on that Coco John. It is looking mighty sweet.

Kevin

cont... 00-14, with strings

-

Kevin in California

- Posts: 2799

- Joined: Mon Dec 19, 2011 4:19 pm

-

John Parchem

- Posts: 2749

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: Starting to put together a 00-14 fret to the body guitar

I have only a couple of more coats on the backs and sides and I am finished spraying. So far it all looks good. After 8 coats on the top I filled some gaps near the bindings and around the rosette, leveled the top some and sprayed 2 more coats. The back and sides were completely leveled during prep and pore fill so I have not leveled the back or sides while finishing but it looks really level and no gaps showing up so I will just sand level after the lacquer clears.

Cutting the pearl and ebony for the head stock when really well this time. The two pieces fit with no need for full.

Cutting the pearl and ebony for the head stock when really well this time. The two pieces fit with no need for full.

-

John Parchem

- Posts: 2749

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: cont... 00-14, making CF reinforced Edonized Walnut brid

While waiting for the finish to cure, I made the bridge. This bridge is basically from the Gore\Gilet Contemporary Acoustic Guitar Design and Build Build book. The shape is right from the Medium size Acoustic plan shipped with the book. The bridge is reinforced with carbon fiber fabric and I use it in combination with a 1 mm thick hardwood CF reinforced bridge patch. This gives me a very light bridge but one with good lateral stiffness from the two separated parallel carbon fiber sheets.

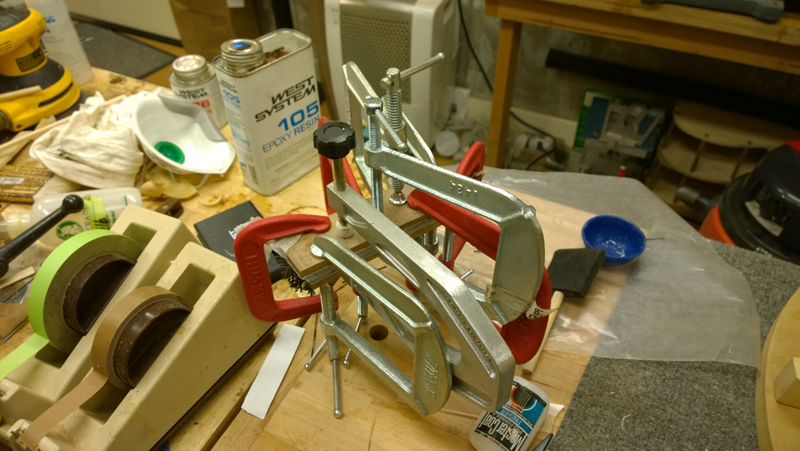

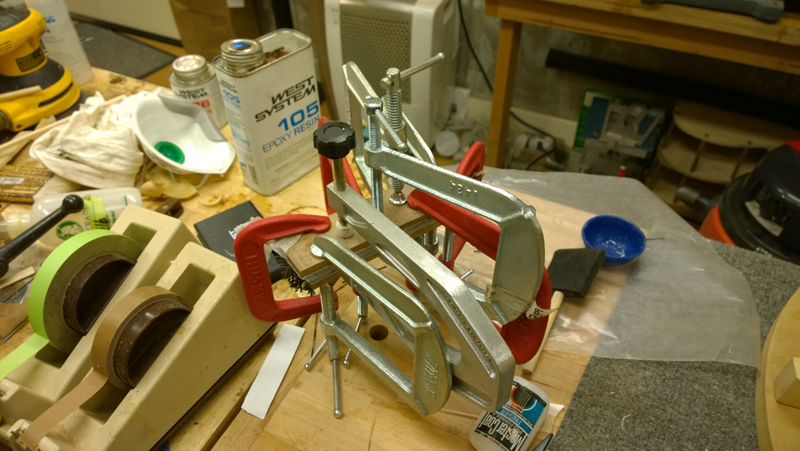

The first task is to rip a 12 mm Walnut bridge blank so that you end up with an 8 mm thick slice and a 3 mm slice. I clean up the gluing faces on each side with a plane and use epoxy to laminate them with a sheet of carbon fiber fabric in between. I let the epoxy cure over night.

I clean up the top edge with a plane, tape on a template and first cut very close to the template with a band saw. I clean up the profile of a belt sander. I use to route to the template, but I have been getting spooked shaping with the router. Also it just takes a moment to cut out the shape and clean it on the band saw. I also drill the bridge pin holes before removing the template.

With some drawn out guide lines I use my Luthier's Friend as a drum sander to thin the wings. I just keep my eye on the guide lines in the early cuts. Once the cut is deep enough it is easy to feel how far to go. Although my final target for the wings are 2 mm. I only take them down to about 4 mm or so at this stage. Ultimately I will end up with a 9-10 mm high with 2 mm or so thick wings.

I put a 16: radius on the top of my bridges. I use a wood radius block to sand the radius on to the top. I take a bunch of care not to over sand the sides and expose the CF on the top of the bridge.

At this point the bridge is roughed out. I use stewmac bevel cutter to bevel the pin holes and then finished sanded the bridge. I ended up a bit tall and took 1.5 mm off of the bottom of this bridge and then radiused the bridge to match the 32 foot radius of the top.

Then the magic ebonizing solution. (1 quart apple cider vinegar, one 0000 steel wool pad, washed of any oil, and well rinsed to remove soap). After sitting in the vinegar for about a week it is good to go. The blackening is not a stain rather it is a chemical reaction between the tannin in the wood and the iron oxide in the solution. The wood is changed deep enough to allow for some finish sanding. Also no problem just putting on more.

The first task is to rip a 12 mm Walnut bridge blank so that you end up with an 8 mm thick slice and a 3 mm slice. I clean up the gluing faces on each side with a plane and use epoxy to laminate them with a sheet of carbon fiber fabric in between. I let the epoxy cure over night.

I clean up the top edge with a plane, tape on a template and first cut very close to the template with a band saw. I clean up the profile of a belt sander. I use to route to the template, but I have been getting spooked shaping with the router. Also it just takes a moment to cut out the shape and clean it on the band saw. I also drill the bridge pin holes before removing the template.

With some drawn out guide lines I use my Luthier's Friend as a drum sander to thin the wings. I just keep my eye on the guide lines in the early cuts. Once the cut is deep enough it is easy to feel how far to go. Although my final target for the wings are 2 mm. I only take them down to about 4 mm or so at this stage. Ultimately I will end up with a 9-10 mm high with 2 mm or so thick wings.

I put a 16: radius on the top of my bridges. I use a wood radius block to sand the radius on to the top. I take a bunch of care not to over sand the sides and expose the CF on the top of the bridge.

At this point the bridge is roughed out. I use stewmac bevel cutter to bevel the pin holes and then finished sanded the bridge. I ended up a bit tall and took 1.5 mm off of the bottom of this bridge and then radiused the bridge to match the 32 foot radius of the top.

Then the magic ebonizing solution. (1 quart apple cider vinegar, one 0000 steel wool pad, washed of any oil, and well rinsed to remove soap). After sitting in the vinegar for about a week it is good to go. The blackening is not a stain rather it is a chemical reaction between the tannin in the wood and the iron oxide in the solution. The wood is changed deep enough to allow for some finish sanding. Also no problem just putting on more.

Re: cont... 00-14, making CF reinforced Edonized Walnut brid

John - this is looking great. I'm thinking about trying to ebonize some walnut - great to see it in action.

Re: cont... 00-14, making CF reinforced Edonized Walnut brid

Well done John. Nice to see your vingar/iron solution work. Something for me to keep in mind. Thanks.

Herman

Herman

-

John Parchem

- Posts: 2749

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: cont... 00-14, out of the spray booth.

Thanks, Herman I am taking a liking to the ebonized Walnut bridges.

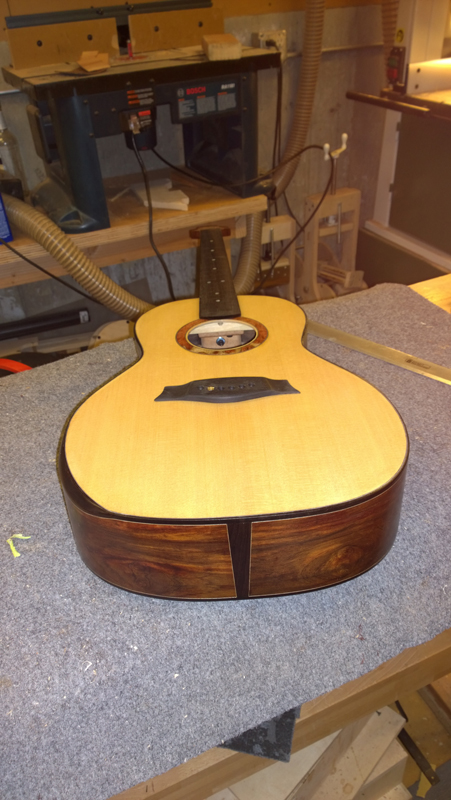

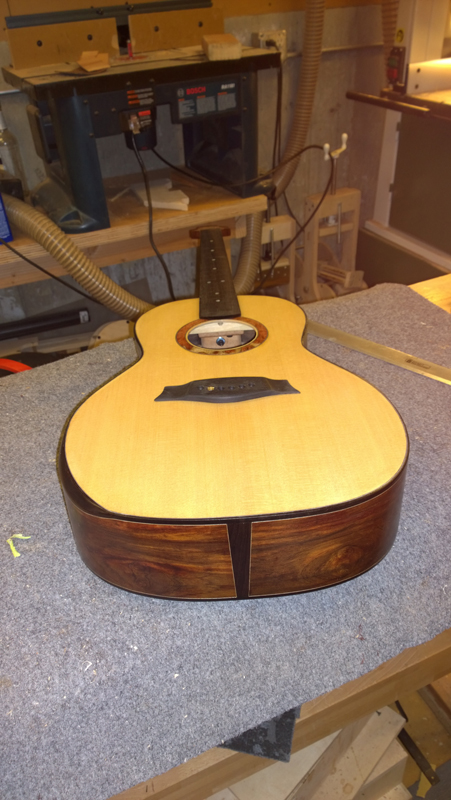

I just pulled this guitar out of the spray booth this afternoon . I am going to wait until the morning until I start wet sanding and buffing out the finish. I think I am getting better with the spray gun as these pictures are the guitar 15 or so coats of EM6000 lacquer with no level sanding. Not a sag, orange peel, over spray or drip to be found.

I just pulled this guitar out of the spray booth this afternoon . I am going to wait until the morning until I start wet sanding and buffing out the finish. I think I am getting better with the spray gun as these pictures are the guitar 15 or so coats of EM6000 lacquer with no level sanding. Not a sag, orange peel, over spray or drip to be found.

Re: cont... 00-14, out of the spray booth.

Lookin sweet