continuing build thread for Gore Medium body SS

-

Justin Hill

- Posts: 1

- Joined: Sat Jun 07, 2014 10:06 pm

Re: continuing build thread for Gore Medium body SS

Wow! That is looking very good! I love following the build process, great job documenting.

-

John Parchem

- Posts: 2750

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

Thanks guys,

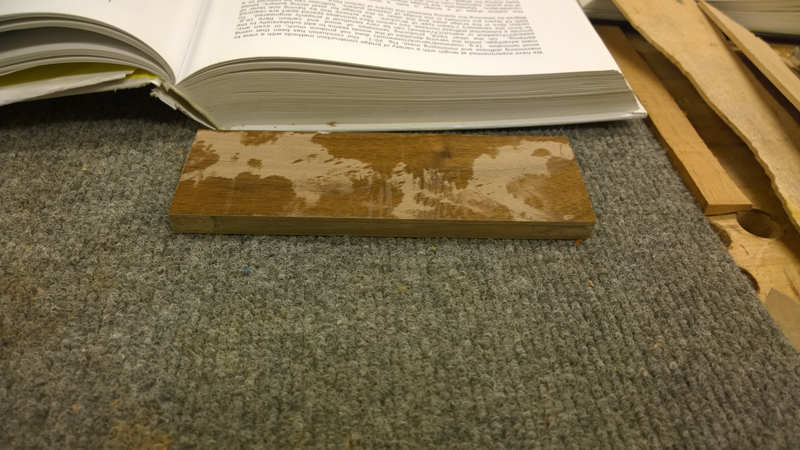

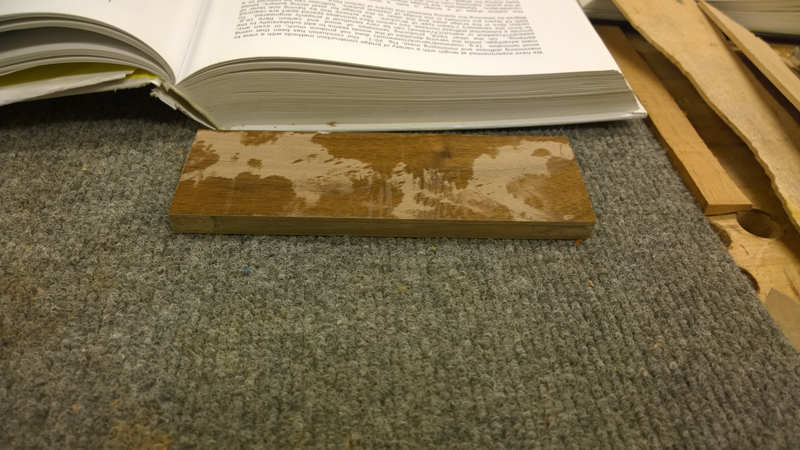

I am going to use a carbon reinforced walnut bridge of this guitar due to it lower density. I can make a much lighter bridge with walnut than with rosewood or ebony. I want the bridge to be dark so following sugestions in the book I will ebonize the walnut. Ebonizing the wood relies on a chemical reaction between the tannins in the wood and iron oxide in a made up solution of steel and vinegar.

The walnut I have will ebonize just fine, that is it has enough tannin in it. I started two batches of vinegar/steel wool one with an absolutely new and clean (I worked to wash out any oils) steel wool pad and the second a steel wool pad I rusted with salt water and then washed out. The streak on the left was three days of one pad of 0000 steel wool in a quart of white wine vinegar, the right pad is two days of a somewhat rusted steel wool pad in a quart of vinegar. In both cases the steel wool has not dissolved even close to all the way.

The wood stained very quickly and is quite dark.

I am going to use a carbon reinforced walnut bridge of this guitar due to it lower density. I can make a much lighter bridge with walnut than with rosewood or ebony. I want the bridge to be dark so following sugestions in the book I will ebonize the walnut. Ebonizing the wood relies on a chemical reaction between the tannins in the wood and iron oxide in a made up solution of steel and vinegar.

The walnut I have will ebonize just fine, that is it has enough tannin in it. I started two batches of vinegar/steel wool one with an absolutely new and clean (I worked to wash out any oils) steel wool pad and the second a steel wool pad I rusted with salt water and then washed out. The streak on the left was three days of one pad of 0000 steel wool in a quart of white wine vinegar, the right pad is two days of a somewhat rusted steel wool pad in a quart of vinegar. In both cases the steel wool has not dissolved even close to all the way.

The wood stained very quickly and is quite dark.

- Attachments

-

- ebonise.jpg (176.26 KiB) Viewed 333 times

Re: continuing build thread for Gore Medium body SS

That Z-poxy really enriched to look of the back and sides.

This is an impressive build.

This is an impressive build.

John

Re: continuing build thread for Gore Medium body SS

Why bother with carbon reinforcement for the bridge? Or is it a decorative element? I know that Ovation's have non-reinforced pin-less bridges made of Walnut. Lightweight is good -- I totally agree with that concept.

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

-

John Parchem

- Posts: 2750

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

The carbon fiber paired with the fiber between the bridge plate and the top (forming an I beam) provides a stiff cross grain brace. This is important for the falcate braced design as the bridge is the only cross brace for the center of the guitar. Also the carbon fiber will help prevent splitting around the bridge holes or slot.ken cierp wrote:Why bother with carbon reinforcement for the bridge? Or is it a decorative element? I know that Ovation's have non-reinforced pin-less bridges made of Walnut. Lightweight is good -- I totally agree with that concept.

Re: continuing build thread for Gore Medium body SS

OK I get that -- thanks

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

-

John Parchem

- Posts: 2750

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: continuing build thread for Gore Medium body SS

Here is a sequence of photos making a carbon fiber reinforced bridge for the falcate brace guitar out of walnut. Unlike an x-braced guitar the falcate bracing pattern does not have a cross brace across the center of the top in the lower bout so the bridge is used to provide a stiff brace. You will see in the pictures that I laminated carbon fiber in a walnut bridge blank. Walnut was use to as a bridge made with walnut is substantially lighter than an ebony or a rosewood bridge.

I also used a vinegar\steel wool solution to ebonize the walnut to give it an ebony look. That process is like magic and worked amazingly well.

I may make another bridge as I sanded it to the carbon fiber when putting on a 16" radius. It is not super noticeable as it is black on black after I ebonized the walnut. But doing the first is part of learning.

I cut out the shape on a band saw very close and just sanded to the final shape using the template as my guide. I have gotten to where I hate to shape on a router.

I shaped the wings with my luthiers friend in its drum sanding mode.

So far so good.

Here is where things went wrong I sanded a little deep when sanding the 16" radius on the bridge and expose some fiber on the top of the bridge

You can see the fiber. Next time I will have the top veneer a little thicker. Note the weight right around 22 grams with more sanding to go.

I used a brush to apply the the vinegar with dissolved steel wool. This pictures is the length of time to get my camera later.

You can see it is not a bad match for ebony. The ebony bridge in the picture weighs 35 grams.

I also used a vinegar\steel wool solution to ebonize the walnut to give it an ebony look. That process is like magic and worked amazingly well.

I may make another bridge as I sanded it to the carbon fiber when putting on a 16" radius. It is not super noticeable as it is black on black after I ebonized the walnut. But doing the first is part of learning.

I cut out the shape on a band saw very close and just sanded to the final shape using the template as my guide. I have gotten to where I hate to shape on a router.

I shaped the wings with my luthiers friend in its drum sanding mode.

So far so good.

Here is where things went wrong I sanded a little deep when sanding the 16" radius on the bridge and expose some fiber on the top of the bridge

You can see the fiber. Next time I will have the top veneer a little thicker. Note the weight right around 22 grams with more sanding to go.

I used a brush to apply the the vinegar with dissolved steel wool. This pictures is the length of time to get my camera later.

You can see it is not a bad match for ebony. The ebony bridge in the picture weighs 35 grams.