Florentine Cutaway

-

Dave Bagwill

- Posts: 5952

- Joined: Tue Dec 13, 2011 7:44 pm

Re: Florentine Cutaway

I use a can of Harry & David's Turkey rub for my soundhole bindings to wrap around. I don't like the rub itself, though..

-Under permanent construction

Re: Florentine Cutaway

I've heard of the old turkey rub trick. Does it work on chickens as well?

-

Dave Bagwill

- Posts: 5952

- Joined: Tue Dec 13, 2011 7:44 pm

Re: Florentine Cutaway

Very professional paint can. Very professional sanding. From where I am sitting, it looks like you know what you are doing.

Re: Florentine Cutaway

Never had that turkey rub, but I sure like Anja's rub. And don't hijack the tread with the can. This is serious matter. :-)

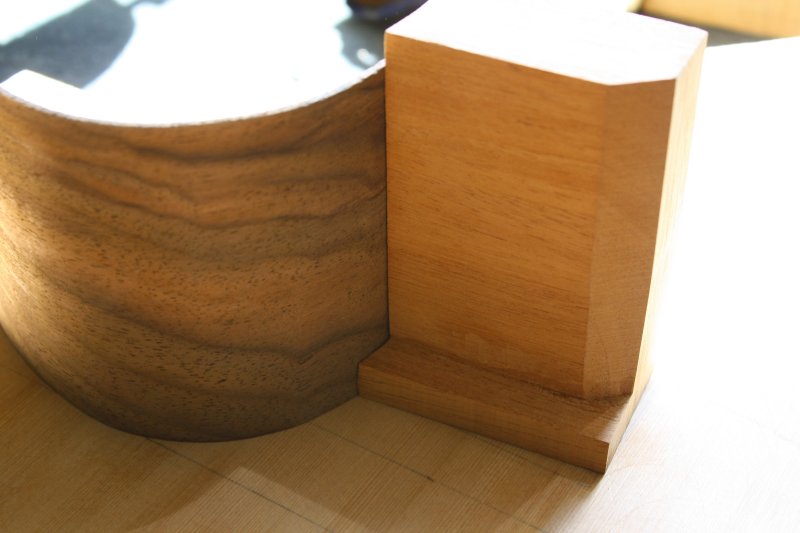

Next: The bending of the sides. This black walnut surprisingly bends like butter. Never had this easy wood.

I cut it straight off at the marked cutawaypoint and bended the cutawaycurve. I was able to bend it right from the edge, so it follows up the figure from the sides.

The match to the neckblock is quite nice. Not a 100% snug fit, but with epoxy no one will notice.

It worked out to get a smooth curve:

Nice walnut. Browns, greys, greens, and a bit of orange. Me like.

Next: The bending of the sides. This black walnut surprisingly bends like butter. Never had this easy wood.

I cut it straight off at the marked cutawaypoint and bended the cutawaycurve. I was able to bend it right from the edge, so it follows up the figure from the sides.

The match to the neckblock is quite nice. Not a 100% snug fit, but with epoxy no one will notice.

It worked out to get a smooth curve:

Nice walnut. Browns, greys, greens, and a bit of orange. Me like.

Re: Florentine Cutaway

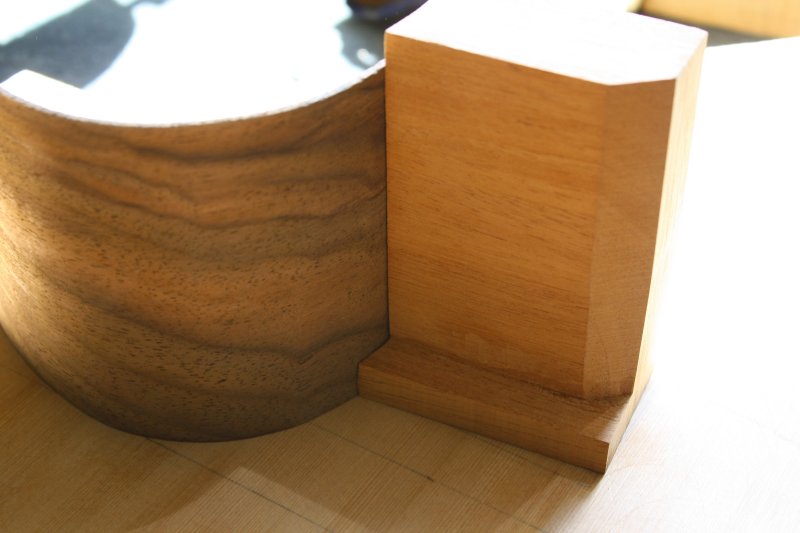

Clamping of the tail- and neckblock.

First the tailblock was clamped. All should be straight and snug. No pics, 'cause there is nothing special to it.

The neckblock has to be flat and perpenducular to the workboard and the sides. I had always some trouble to keep the neckblock flat to the mold, because of the moldfasteners were in the way of clamps. so I thought: why not screw the block to the mold. Therefore I drilled holes though the mold for some screws to be attached in the neckblock. These on a place where later on the dovetail will be routed. No visable marks in the end. Check first if the inside of the mold is perpendicular!

(Before gluing, do a dry-test!). No very hightech, but to my amateur skills, plain brilliant ;-)

Now glue is applied and all is made together in the complete mold. Screws fastened and the alligment is checked.

Now it is possible to open the cutawayside the mold, so overall clamping is easier

First the tailblock was clamped. All should be straight and snug. No pics, 'cause there is nothing special to it.

The neckblock has to be flat and perpenducular to the workboard and the sides. I had always some trouble to keep the neckblock flat to the mold, because of the moldfasteners were in the way of clamps. so I thought: why not screw the block to the mold. Therefore I drilled holes though the mold for some screws to be attached in the neckblock. These on a place where later on the dovetail will be routed. No visable marks in the end. Check first if the inside of the mold is perpendicular!

(Before gluing, do a dry-test!). No very hightech, but to my amateur skills, plain brilliant ;-)

Now glue is applied and all is made together in the complete mold. Screws fastened and the alligment is checked.

Now it is possible to open the cutawayside the mold, so overall clamping is easier

Re: Florentine Cutaway

I have always failed to understand the need/use of those big honk'in toggle things -- for the very reason you've sighted, to me they just get in the way. Great idea securing the neck block from the outside of the mold. We recommend stabilizing the block with screws in our assembly manual, but that is from the inside -- your way is more accessible.

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html