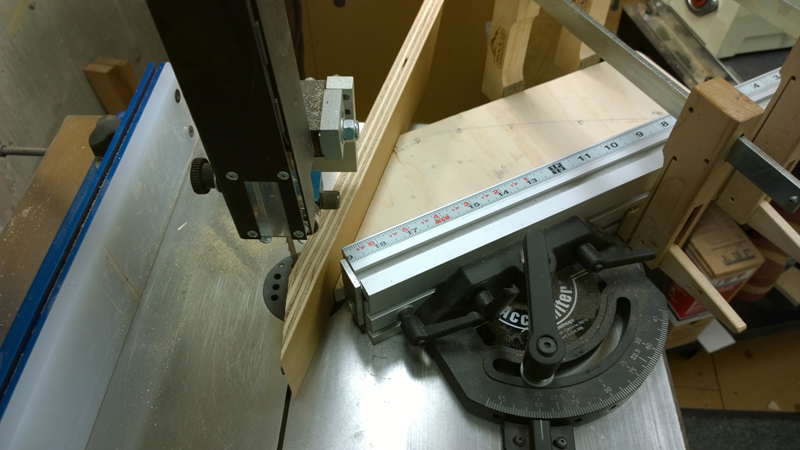

This last week I made my first scarf joint neck blank. I have been cutting necks out of single pieces of wood. I have sort of been scared of the joint as I can not cut a straight line on the band saw. Luckily my kids bought me a miter guide for my band saw. I could not cut a 15° with it but I cut some plywood at a 45 degree angle allowing to set and hold my scarf angle. It actually worked and I got a clean cut. Here are pictures of the process, including my bone headed screw up.

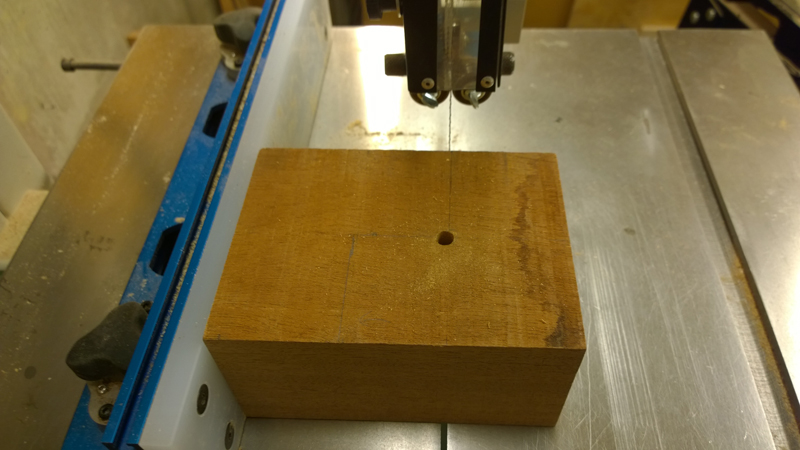

First I used my jointer plan to square the wood,

Then I cut a 45° angle to use as a guide for the miter. Just to be sure I made a test scarf cut on some scrap plywood

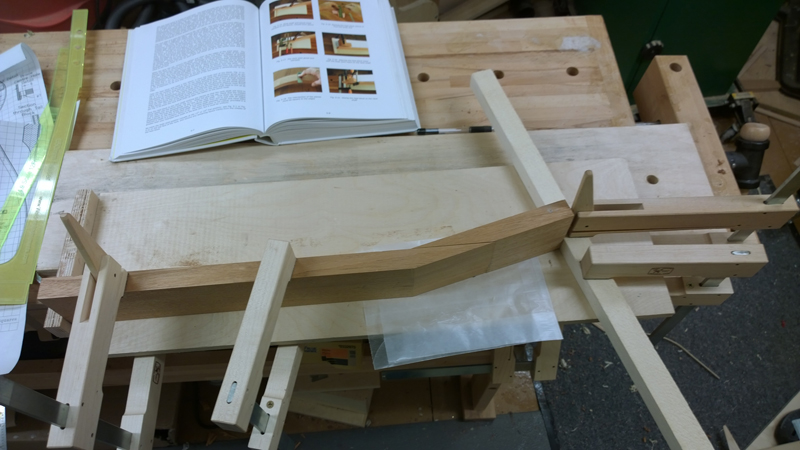

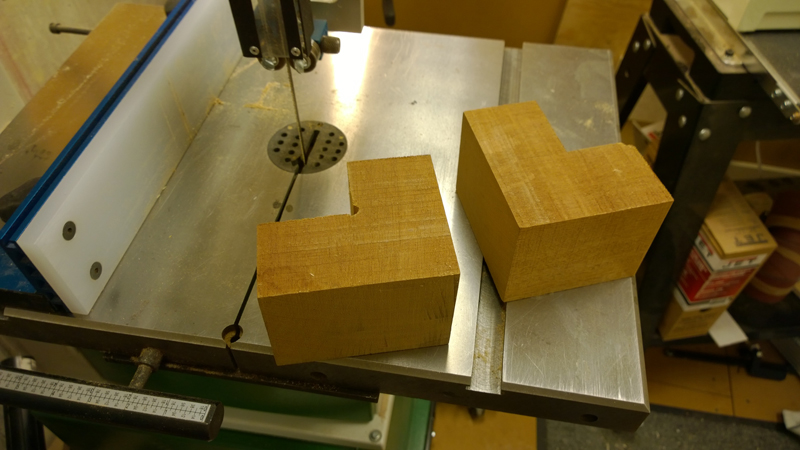

Not sure what I was afraid of the cut when as good as it could on the bandsaw and I just need ot to do a little clean up. I lined up the cut angled pieces and clamp them with a sacrificial piece of MDF, and planed the gluing surface of the joints clean and flat

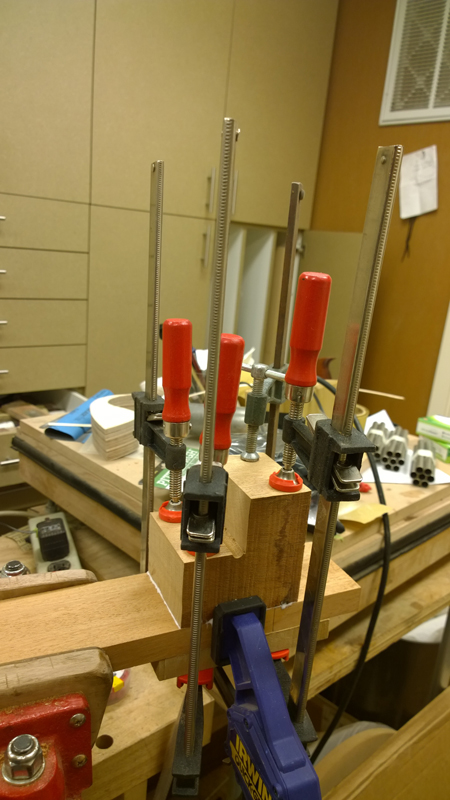

I used my shooting board and some clamps to hold the joint in place and really glued it with some heavy duty clamps.

I had a big block for the heal so I cut it into two heel blanks. Here again I planed the surfaces flat and used some real clamps to glue the heel on the neck.

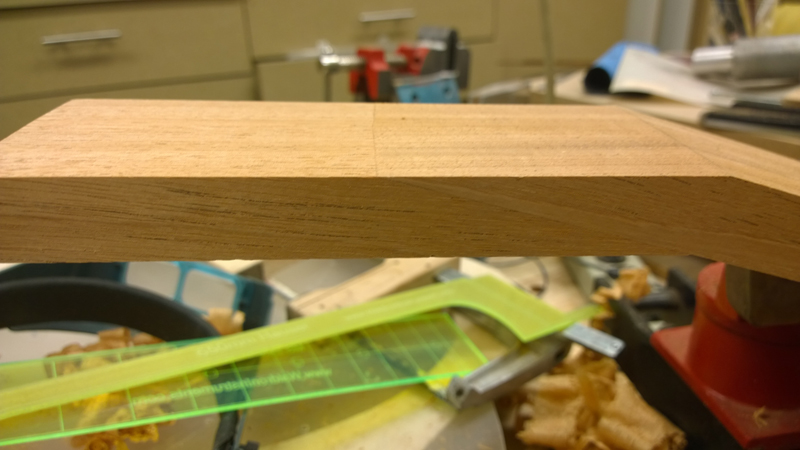

Here is where the bone head maneuver came in to play. I very carefully set up the router table for a truss rod slot right up the center of the neck blank. Then proceed to start the route before tightening the router table fence. Oh well. I cut a strip of mahogany planed it and shaped it to fit in the miss-cut slot. It fit in so nicely that I just wicked in some CA. I reset the table a made a proper slot. No one will see this fix, unless they are changing the fret board in the future for a repair.

.

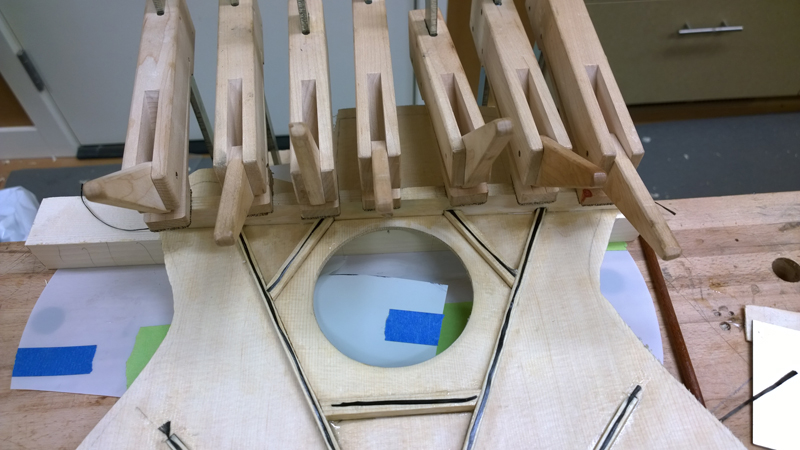

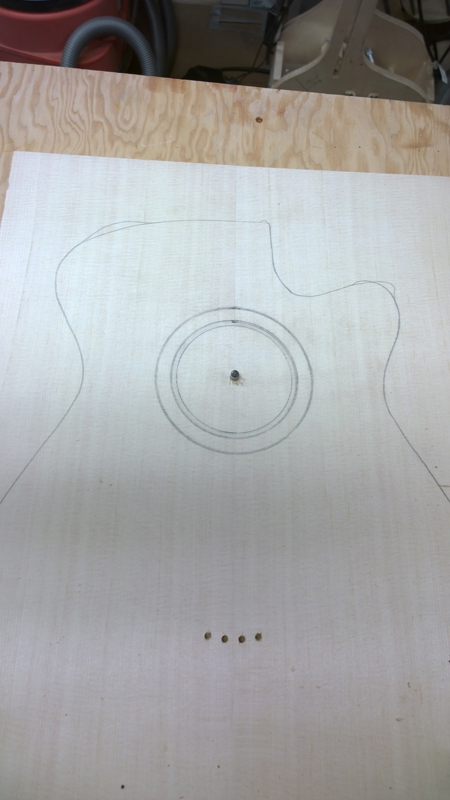

.I also installed an extra amboyna rosette I made as an option for a previous guitar.

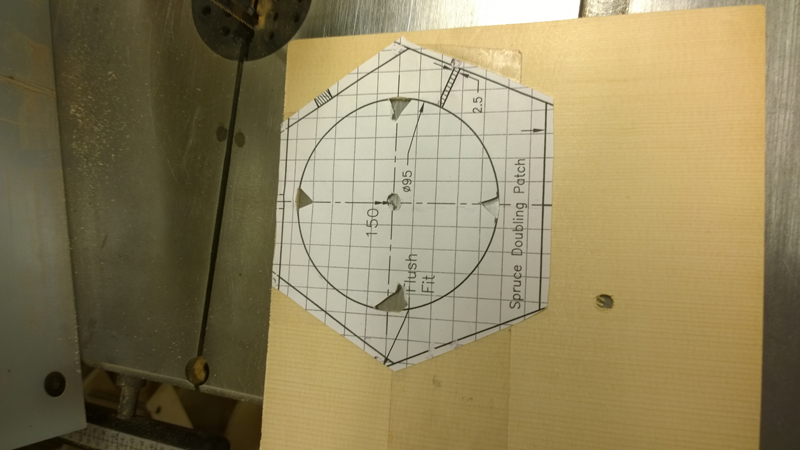

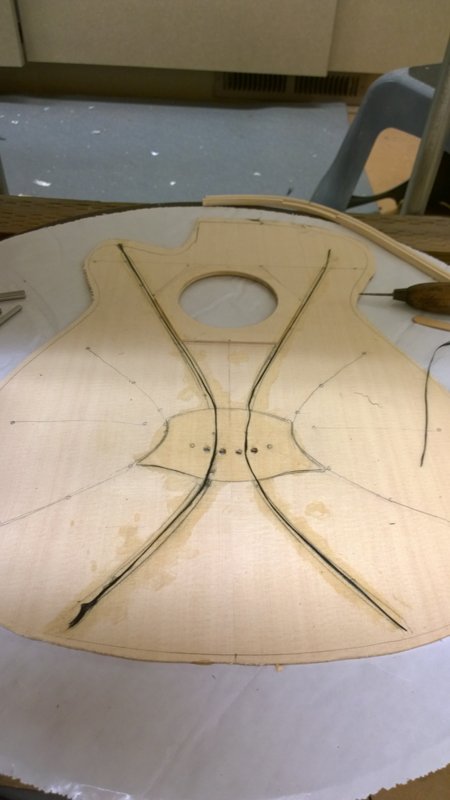

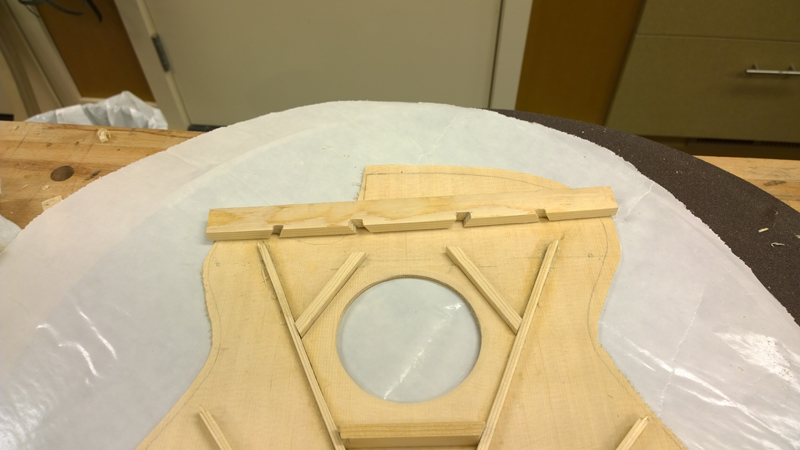

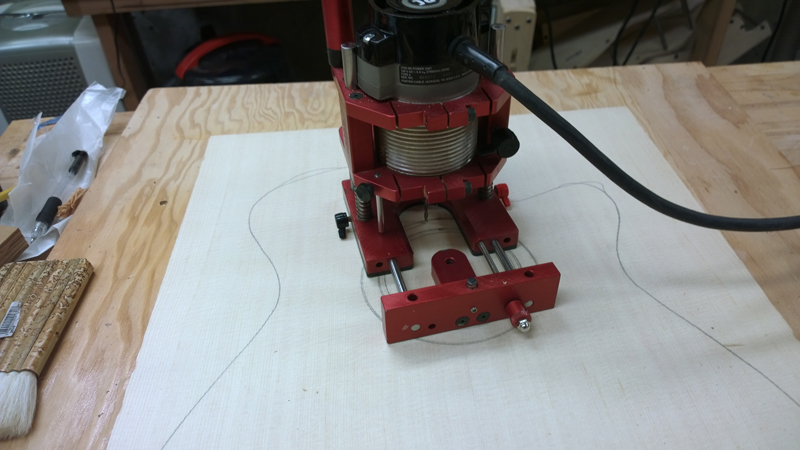

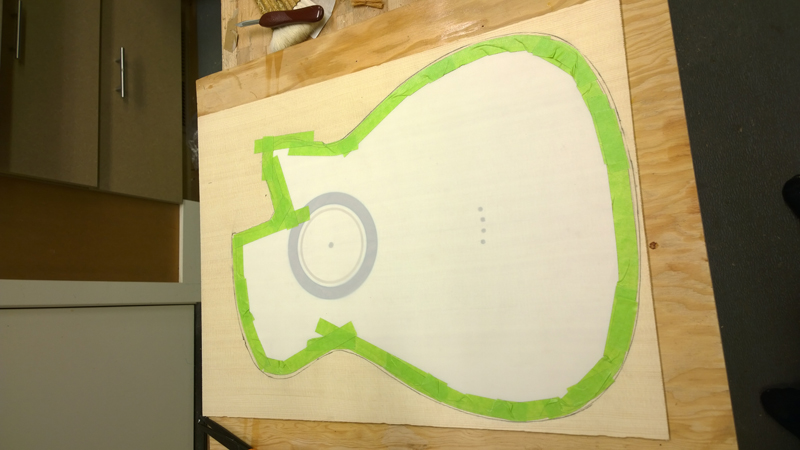

To insure proper bridge and sound hole alignment, and given that I need to drill the peg holes early in the bracing process. I used the template to drill some of the peg holes and the center of the rosette.

I did not do any fancy measurements I just used the router and it fine adjustment to sneak up of the slot I need for the rosette and a couple of thin bwb purflings.

All and all uneventful

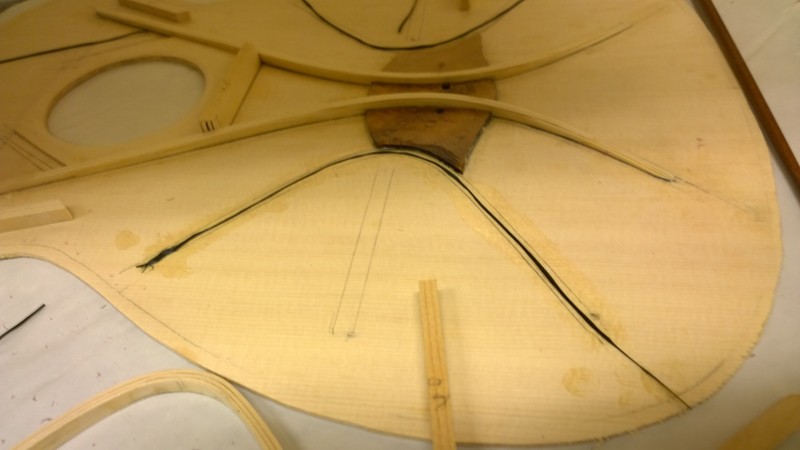

I routed the sound hole such that it should be close to dropping out when the top is the correct thickness.

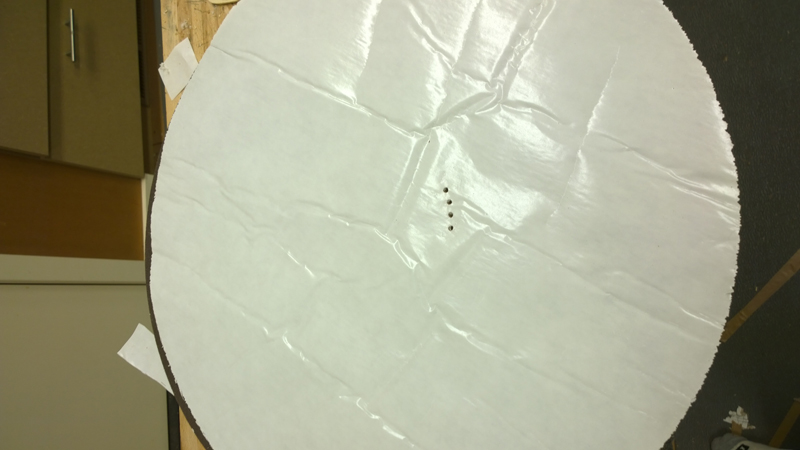

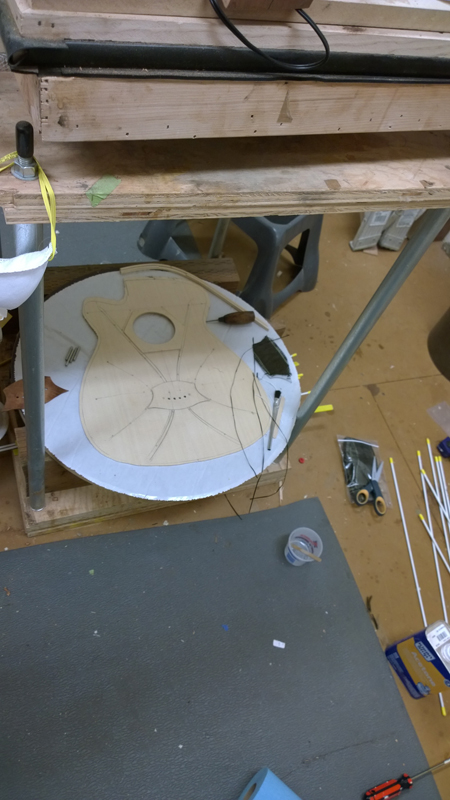

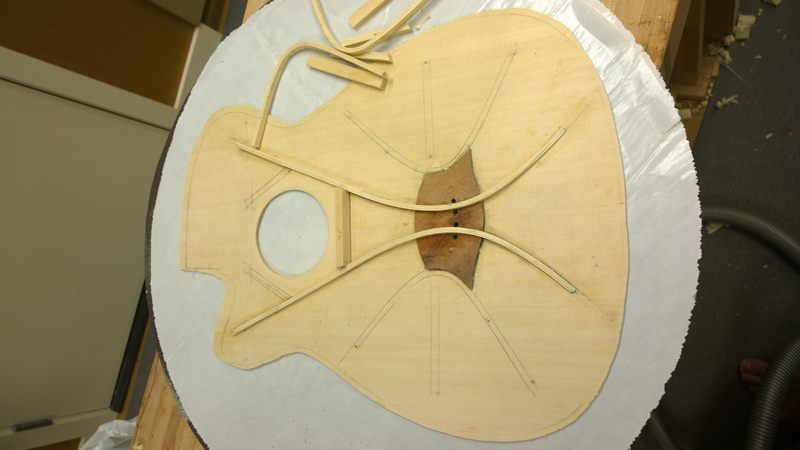

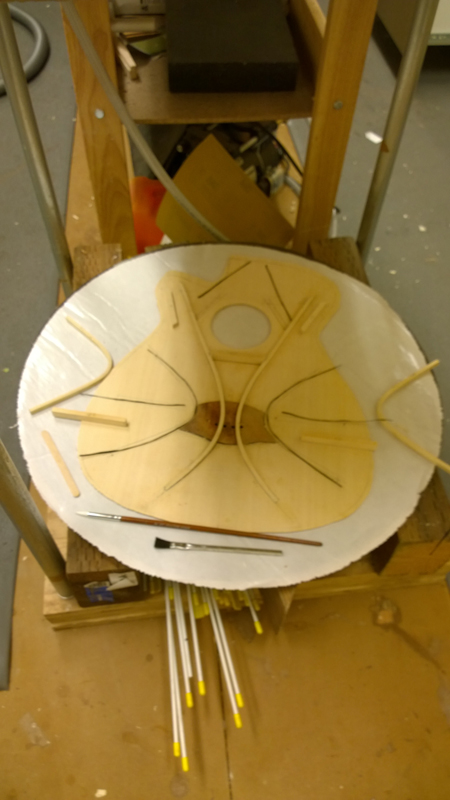

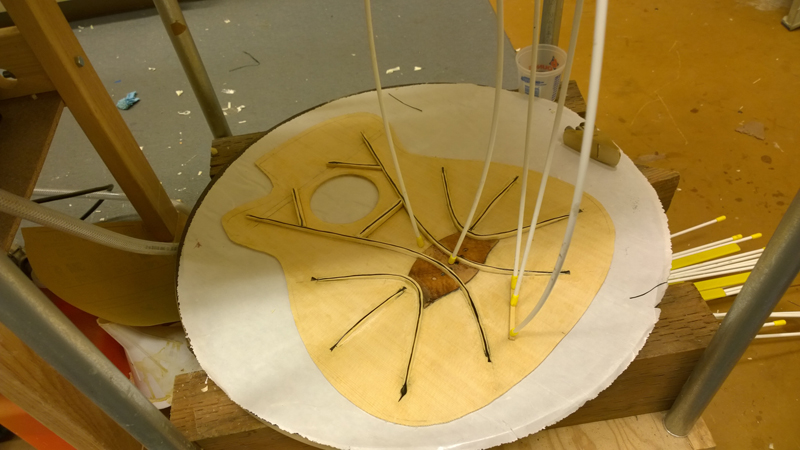

Once very close to the proper thickness I made a 3 mill mylar to cover for the top to protect it during bracing.

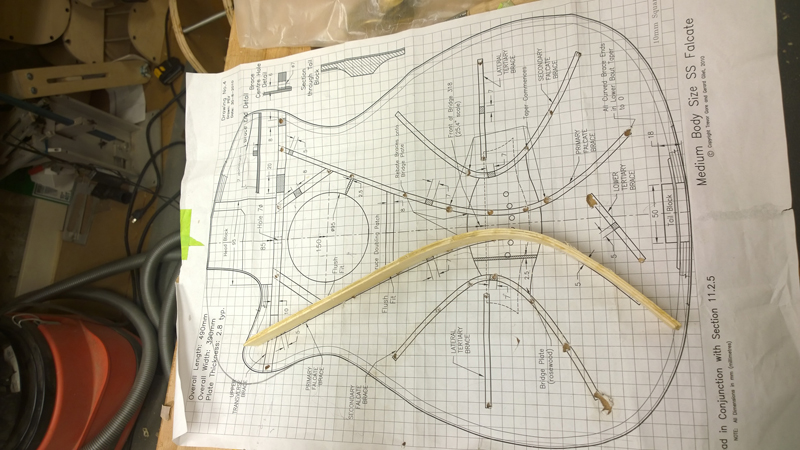

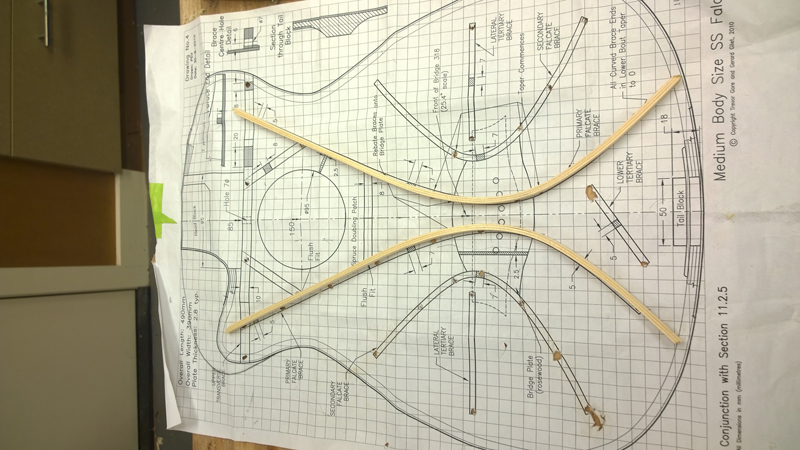

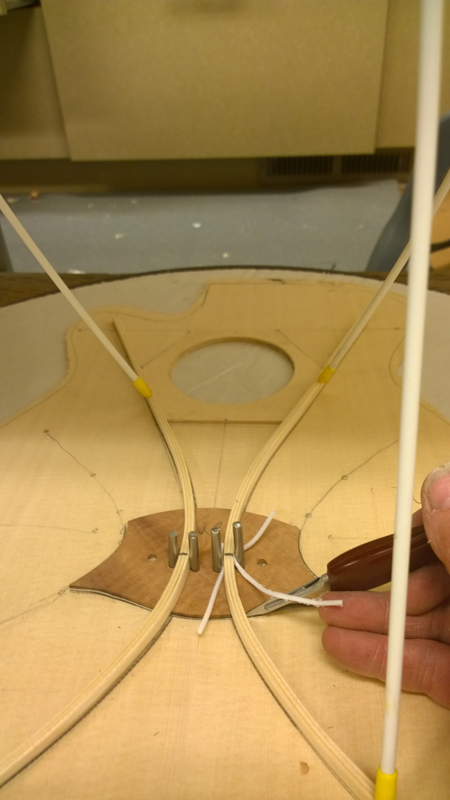

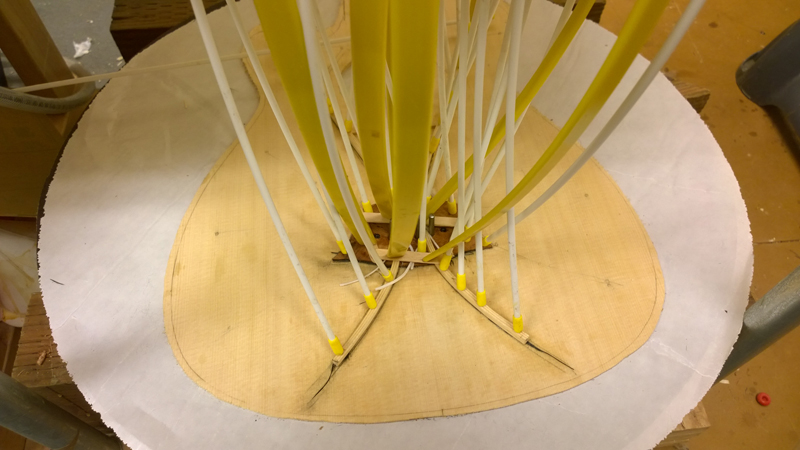

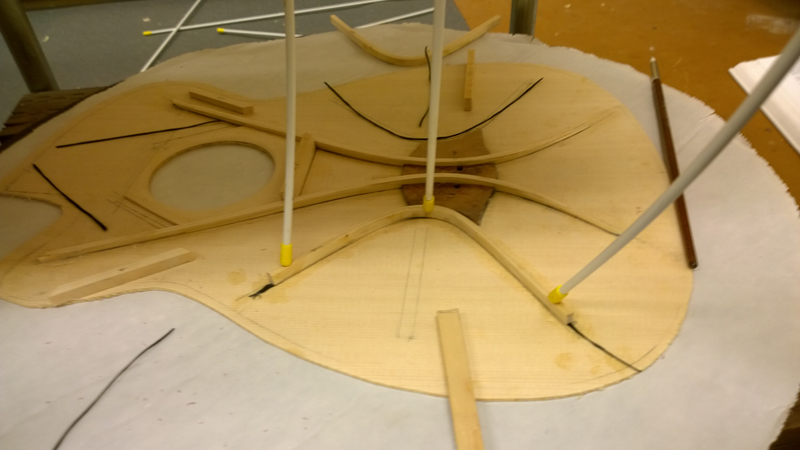

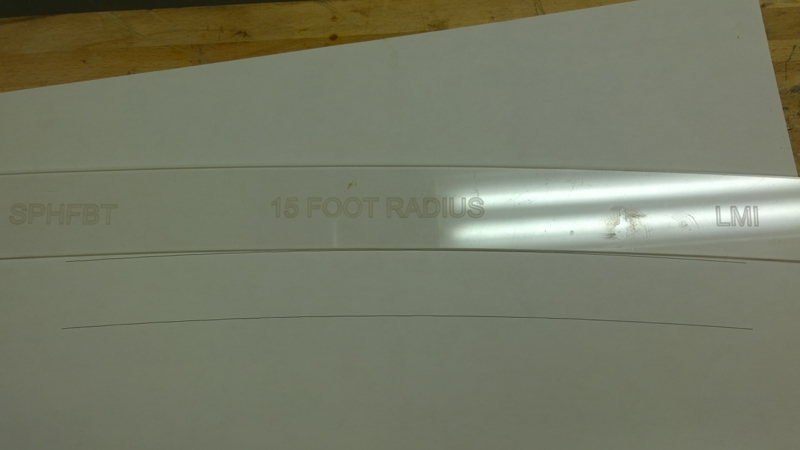

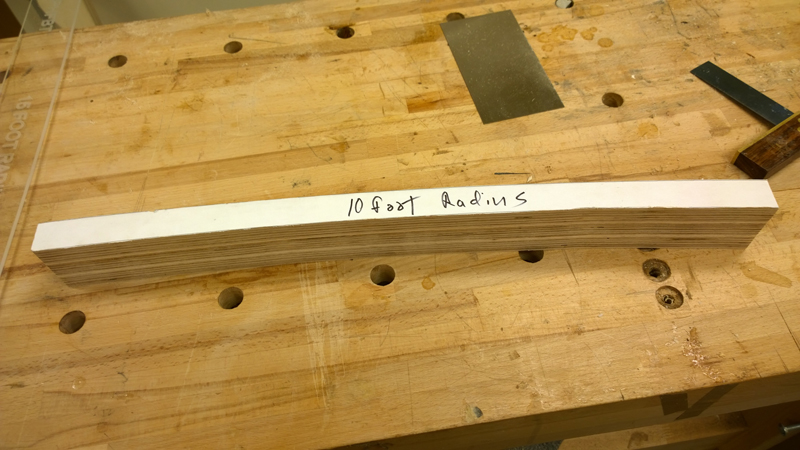

I spent the rest of the weekend preparing to do the top bracing. The last photo shows why I need to drill the peg holes so early; the main braces passes between two peg holes.