Martin 00 cutaway with arm bevel #12 so close

Re: Martin 00 12 Fret - cutaway with arm bevel #12

Nice posting John. Next time you go sailing take me too please:0)

-

Dave Bagwill

- Posts: 5951

- Joined: Tue Dec 13, 2011 7:44 pm

Re: Martin 00 12 Fret - cutaway with arm bevel #12

Really nice, John. It will be a while before I'm ready to tackle the bevel, but I'll use you as a resource! :-)

-Under permanent construction

Re: Martin 00 12 Fret - cutaway with arm bevel #12

Looking good! Iron on veneer great idea.

ken cierp

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

http://www.kennethmichaelguitars.com/

Store Front

http://www.cncguitarproducts.com/

KMG Guitar Kit Information

http://www.kennethmichaelguitars.com/ki ... ckage.html

-

John Parchem

- Posts: 2746

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: Martin 00 12 Fret - cutaway with arm bevel #12

Thanks guys. Lonnie I will keep you in mind. Making iron on veneer is handy, but I need to mention one important safety note: Do not use your wife's iron for this procedure.

I also finished up binding the guitar. Making the bindings for the cut-away is hard. I tried using the fox style bending machine, and bent them ok. But I could not get then out of the unit without the spring steel blowing them up. I tried some tricks to hold the spring steel without success. I finally pulled out my bending iron and did them by hand. Boy those are tight curves. I practiced on the pieces I blew up in the bender. I learned a bunch about using the bending iron. Also by hand I was able to get bindings that matched the curve and held their shape.

I also finished up binding the guitar. Making the bindings for the cut-away is hard. I tried using the fox style bending machine, and bent them ok. But I could not get then out of the unit without the spring steel blowing them up. I tried some tricks to hold the spring steel without success. I finally pulled out my bending iron and did them by hand. Boy those are tight curves. I practiced on the pieces I blew up in the bender. I learned a bunch about using the bending iron. Also by hand I was able to get bindings that matched the curve and held their shape.

-

Kevin in California

- Posts: 2796

- Joined: Mon Dec 19, 2011 4:19 pm

Re: Martin 00 12 Fret - cutaway with arm bevel #12

Good work John, it's going to be sooooooooooooo nice.

Kevin

Kevin

-

John Parchem

- Posts: 2746

- Joined: Fri Dec 23, 2011 8:33 pm

- Location: Seattle

- Contact:

Re: Martin 00 12 Fret - cutaway with arm bevel #12

I mostly got the neck rough carved this weekend.

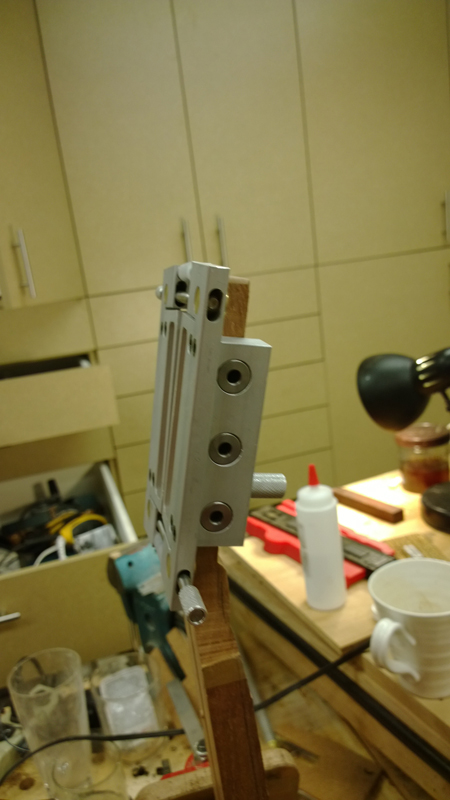

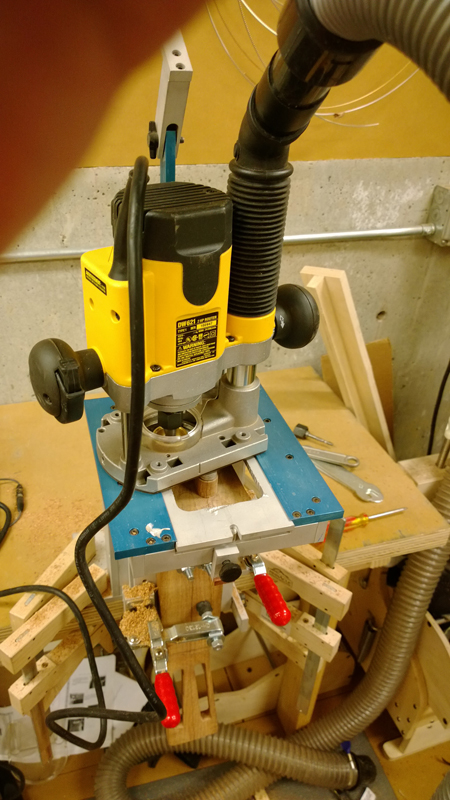

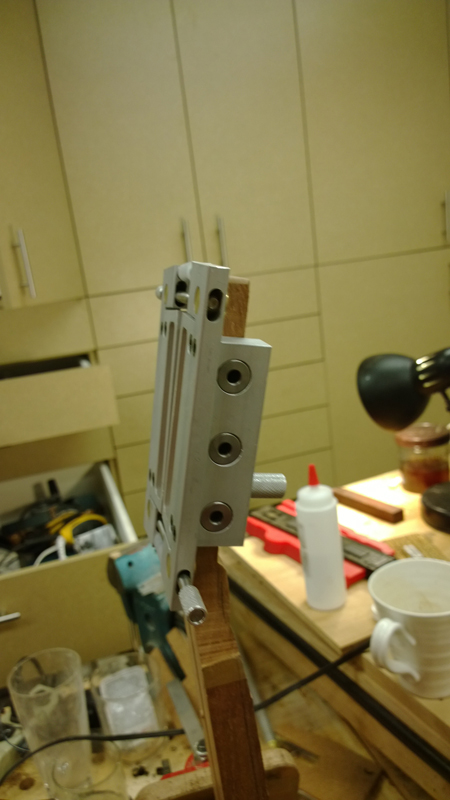

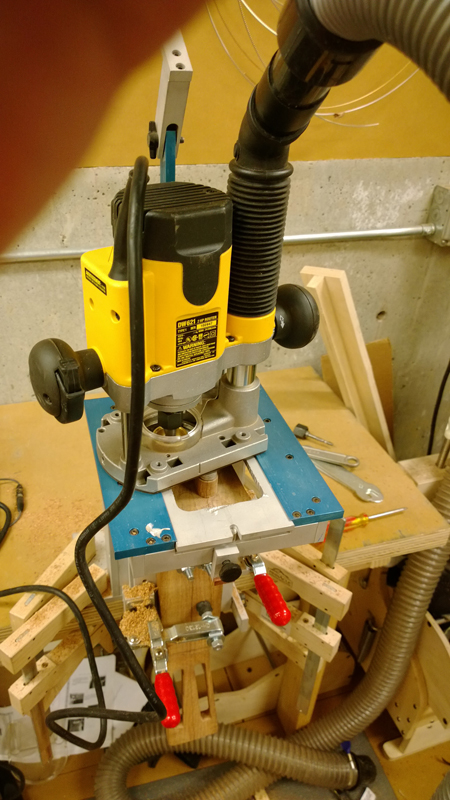

The carving was pretty standard stuff although I did try out my luthier tool slotted head jig for the first time and I have to say that even though it is expensive it does work well. The jig adapts to all most any reasonable shape, I have square end and round end slot templates and drill guide bushings for both classical and steel string tuners. There is little chance of alignment errors with this tool. One the head is in the jig the holes can be drilled and the slots routed without moving the jig.

For this guitar I shaper the head stock by hand with a plane and chisels. I have had enough of using templates against the router. It always seems like it would be faster ... but I am not so sure.

I managed to route the neck angle just right when making the tenon. I changed my procedure slightly. As before I measure and set angle on my neck tenon jig. This time though I routed the bottom of the neck heel block before I routed the tenon. As I route this with the same angle, I can put it on top of the guitar and check the angle and fine tune if necessary.

I still have to do a bunch of fussy stuff to finish the guitar, but it is fun to finally see them at this stage.

The carving was pretty standard stuff although I did try out my luthier tool slotted head jig for the first time and I have to say that even though it is expensive it does work well. The jig adapts to all most any reasonable shape, I have square end and round end slot templates and drill guide bushings for both classical and steel string tuners. There is little chance of alignment errors with this tool. One the head is in the jig the holes can be drilled and the slots routed without moving the jig.

For this guitar I shaper the head stock by hand with a plane and chisels. I have had enough of using templates against the router. It always seems like it would be faster ... but I am not so sure.

I managed to route the neck angle just right when making the tenon. I changed my procedure slightly. As before I measure and set angle on my neck tenon jig. This time though I routed the bottom of the neck heel block before I routed the tenon. As I route this with the same angle, I can put it on top of the guitar and check the angle and fine tune if necessary.

I still have to do a bunch of fussy stuff to finish the guitar, but it is fun to finally see them at this stage.

-

Dave Bagwill

- Posts: 5951

- Joined: Tue Dec 13, 2011 7:44 pm

Re: Martin 00 12 Fret - cutaway with arm bevel #12

Very nice. But it troubles me that I never see any blood on your work, John. It doesn't seem right. :-)

Kidding of course....

Kidding of course....

-Under permanent construction