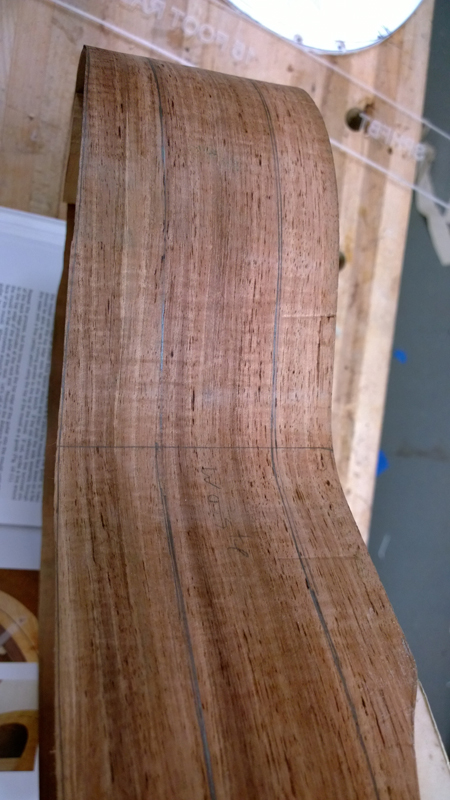

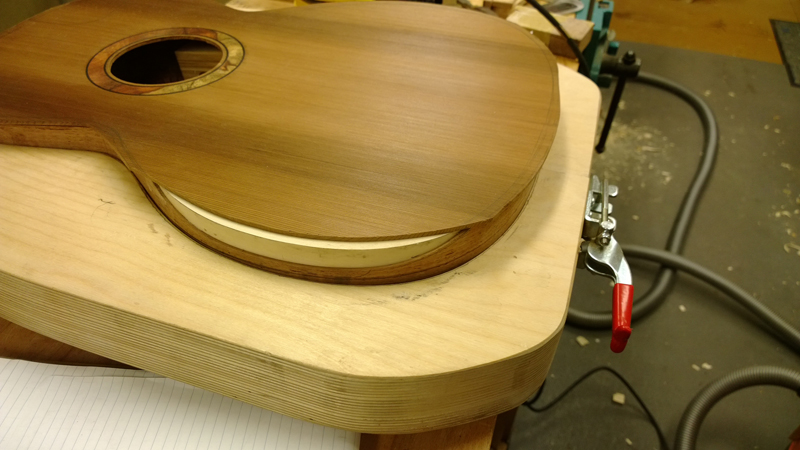

This Koa is pretty figured. The back and sides should be wild.

I found a couple of scrap of some sort of wood at the wood working store to use for the head stock and the rosette and other area.

I think the small plank that I resawed was amboyna burl. These faces do not look like it but the side figure did. The color looks right.

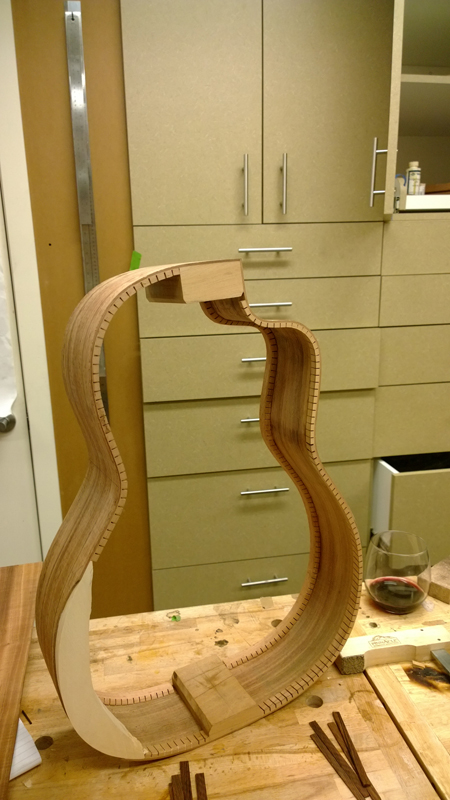

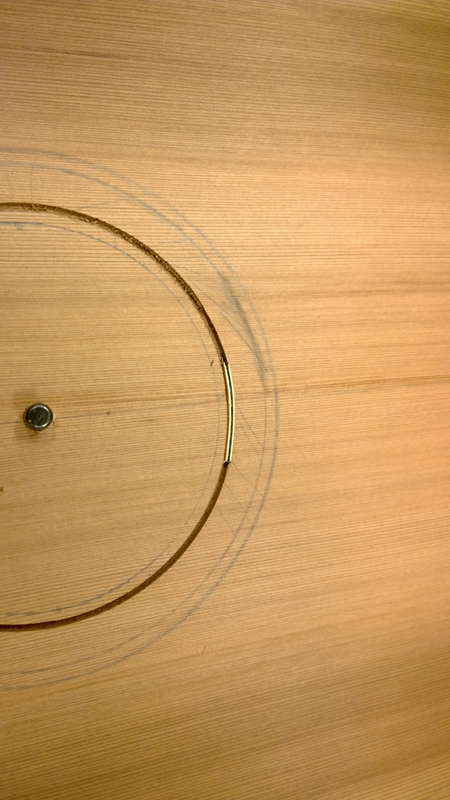

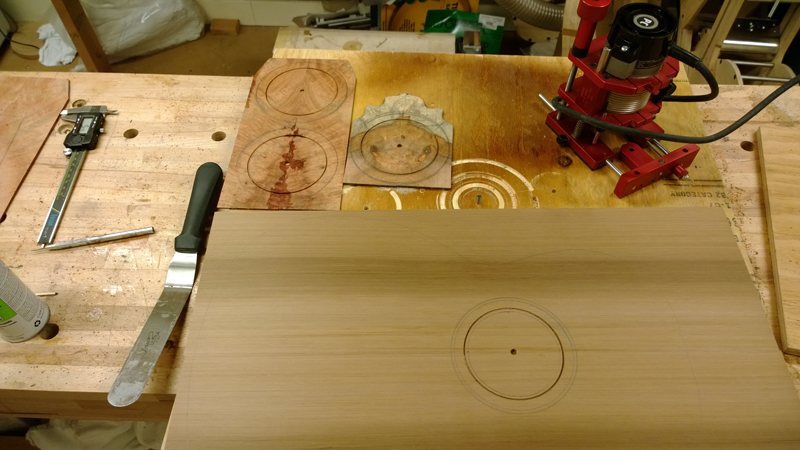

I had another small piece of burl with sap wood that I also resawed and joined for a rosette. I had three choices for rosettes, so I cut them all out the same

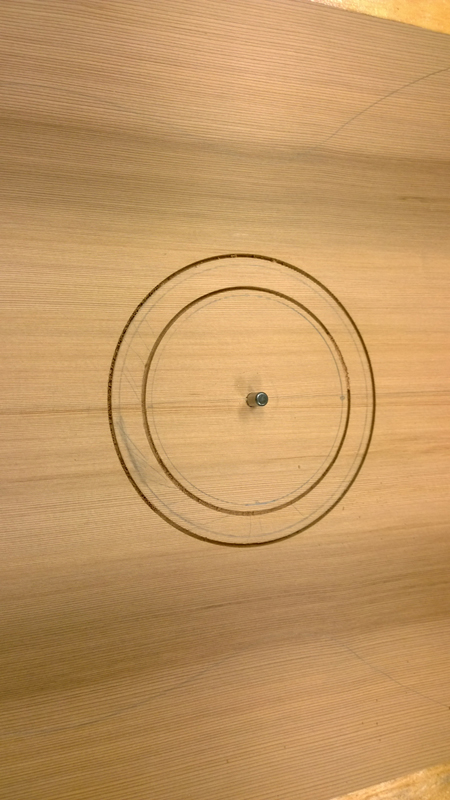

I plan for this rosette to have either bwb or all b bbb purfling inside and out.

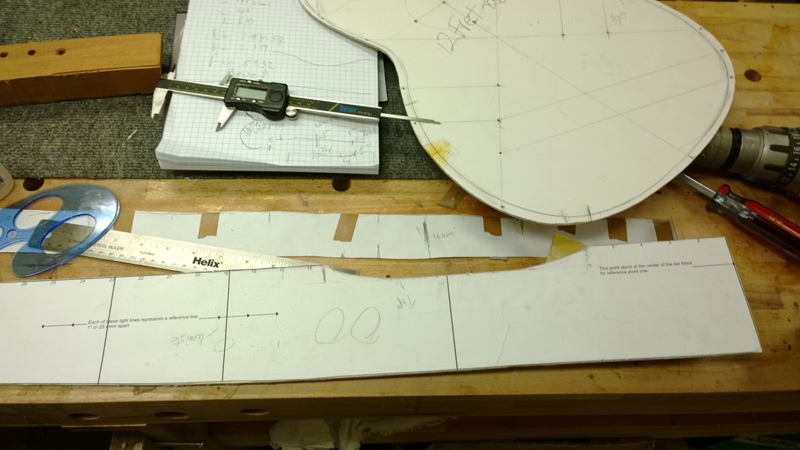

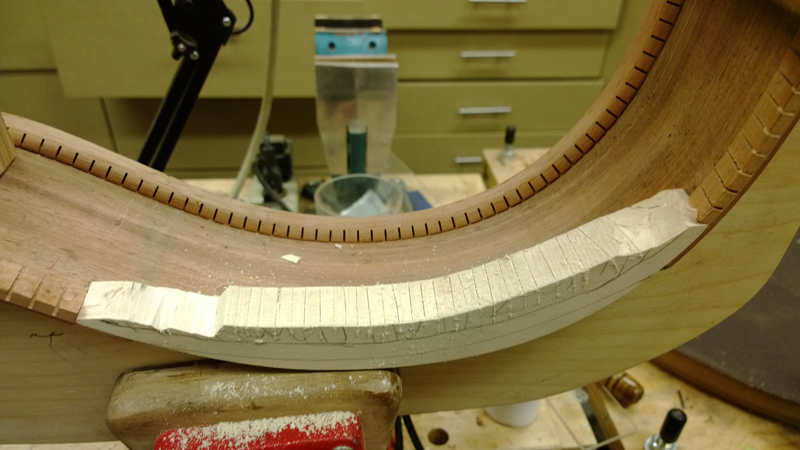

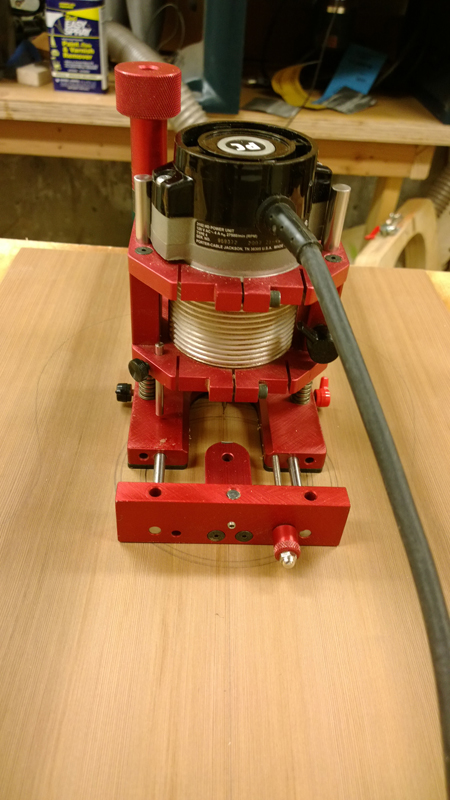

When cutting out the rosette I learned the technique, maybe from Kevin of using a router bit the right diameter for the purfling I want to use. The result is a matching rosette and channel cut in the guitar the correct size for the rosette and the purfling.

First cut a channel where you want the inside or outside purfling on the guitar, leave the router set up exactly and cut the same channel on the rosette stock. I do not cut through the rosette rather I make the rosette the same thickness as the channel is deep. I then cut a channel on the other side on the guitar and again leave the router set up to make the same cut on the rosette stock.

I changed bits on the router and hogged out the center of the channel. I then run the rosettes through the thickness sander back side being sanded till the rosettes drop out (learned this from Rick Davis).

I went with the all black purfling.